Product Short Description

Technical Specifications

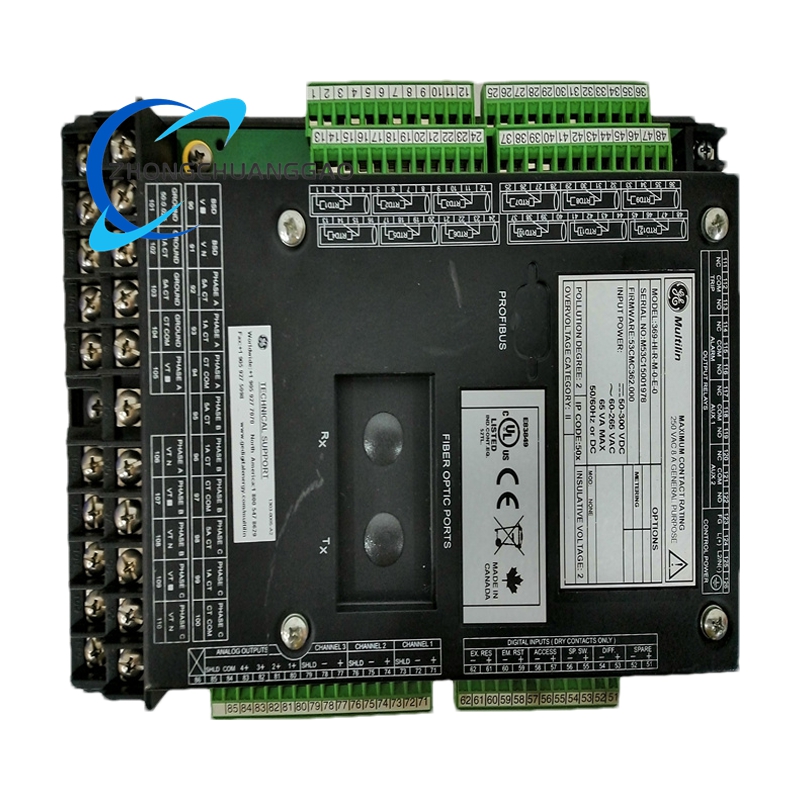

- Electrical Parameters

- The control power input covers 50 – 300V DC and 40 – 265V AC, compatible with 50/60Hz power frequency and adapting to mainstream industrial power supply systems.

- It supports phase current input for medium-sized alternating current motors with a frequency range of 20 – 100Hz, and is applicable to variable frequency drive and two-speed motor systems.

- It is configured with 12 resistance temperature detector inputs that match 100Ω platinum, 100Ω nickel and other types of detectors to monitor stator and bearing temperatures.

- The nominal control power is 20VA, the maximum control power reaches 65VA, and the fuse rating is 3.15A 250V.

- The output current ranges from 0 to 10A, and the output voltage can reach up to 250V AC to meet the control needs of most industrial motors.

- Physical Parameters

- The overall dimensions are approximately 30.5cm × 12.7cm × 20.3cm, and the weight is about 4.5kg, which is convenient for installation and layout in standard control cabinets.

- It adopts a rugged shell design with a protection level of IP65, which can effectively prevent the intrusion of dust and water droplets.

Description

- Environmental Parameters

- The operating temperature range is -20°C to 55°C, and the storage temperature range is -40°C to 85°C, adapting to indoor and outdoor industrial environments.

- It can operate stably in an environment with a non-condensing humidity range of 5% to 95%, avoiding component damage caused by condensation.

Function Features

- Comprehensive and Targeted Motor Protection

It is equipped with an enhanced thermal model that uses resistance temperature detector bias and negative sequence current compensation to prevent rotor heating. It provides overvoltage, undervoltage, overfrequency and underfrequency protection, and the current unbalance protection threshold can be adjusted between 4% – 30%. It can quickly detect locked rotor and mechanical jamming faults and trigger tripping actions immediately, and also provides directional ground overcurrent protection to cover all potential fault points of the motor.

- Precise Metering and Complete Data Recording

It can conduct real-time metering of multiple electrical parameters such as motor current, voltage, power, energy and frequency, and monitor temperature parameters up to 200°C. It can capture 16-cycle oscillographic data when a fault trip occurs or a manual command is issued. It can store the last 512 event records, including motor start-up times, trip causes and thermal capacity usage, providing a full data basis for fault analysis.

- Flexible Communication and Remote Management

It supports multiple communication protocols including Modbus RTU, Modbus TCP/IP and Profibus DP. It is equipped with Ethernet connectivity and RS232/RS485 communication interfaces, and supports 1ms precision IRIG-B time synchronization for event logging. Users can use EnerVista software to remotely configure parameters, update firmware and retrieve data, realizing centralized monitoring and management of motors.

- User-Friendly Operation and Intelligent Diagnosis

It is equipped with a 40-character liquid crystal display and a keypad operation interface, and LED indicators can clearly show the motor’s stop, operation and overload status. It can automatically generate motor health reports, analyze historical operation data to predict maintenance needs, and send early warnings for problems such as broken belts and pump suction loss, reducing troubleshooting time.

Application Scenarios

- Industrial Automation and Manufacturing

It is widely used in motors of production line conveyors, robotic arms, fans and pumps in manufacturing workshops. It is especially suitable for variable frequency drive and two-speed motor systems in discrete manufacturing. It ensures the continuous operation of motors, avoids production line shutdown caused by motor faults, and maintains the stability of the production rhythm.

- Oil and Gas and Petrochemical Industry

It is installed in motor equipment such as compressors, pipeline pumps and injection pumps in oil drilling platforms, refineries and long-distance oil and gas transmission pipelines. Its corrosion-resistant and moisture-proof design can adapt to the harsh offshore and onshore working environments, preventing safety accidents such as oil and gas leakage caused by motor failures.

- Power System and New Energy Field

It is applied to auxiliary motor equipment such as induced draft fans and feed pumps in thermal power plants, as well as motors in wind turbines and solar power generation supporting systems. It protects the stable operation of these motors, ensures the continuous output of electric energy, and can be integrated into the power grid monitoring system to realize unified management.

- Metallurgy and Heavy Industry

It is used to protect motors of key equipment such as cranes, rolling mills and blast furnace air supply fans in metallurgical plants. These equipment bear heavy loads and work continuously for a long time. The relay can quickly respond to faults such as overload and short circuit, avoiding equipment damage and production suspension, and ensuring the smooth progress of metallurgical production processes.

- Building and HVAC Systems

It is applied to motor control in heating, ventilation and air conditioning systems of large commercial buildings, shopping malls and office buildings. It also protects motors of water supply and drainage pumps and elevators in buildings. It ensures the stable operation of these supporting facilities, improves the comfort of the building environment, and guarantees the daily travel and life needs of users.

Reviews

There are no reviews yet.