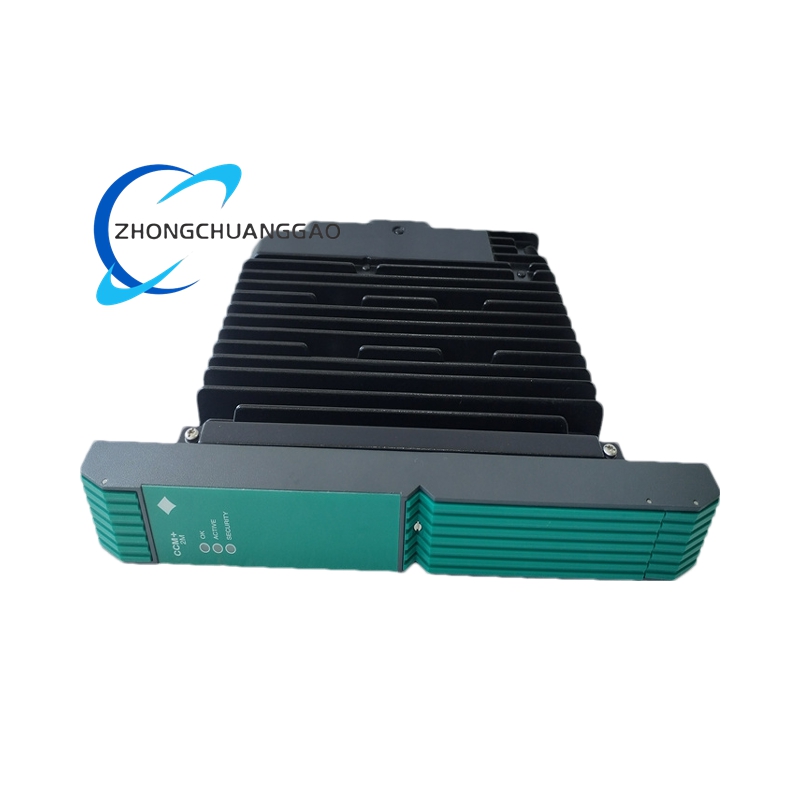

Product Short Description

- Power Supply: 24 VDC, 0.60 A (max)

- Communication Signals: ±15 VDC

- Operating Temperature: Up to 70°C (ambient)

- Certifications: CE, UL compliant; Class I, Division 2, Groups A, B, C & D (hazardous location approval)

- Weight: Approximately 1 kg (1000 g)

- Dimensions: Compact design suitable for DIN rail or panel mounting

- Redundancy Support: Built-in redundancy for fault-tolerant operation

- ROM Version: 3.03

Description

Functional Features

- Advanced Control Strategies:

- Supports PID control, fuzzy logic, and neural network-based algorithms for adaptive process optimization.

- Enables precise tuning of control parameters to match dynamic process conditions.

- High-Speed Processing:

- Delivers millisecond-level response times for rapid safety interlocks and critical action triggering.

- Ensures real-time data acquisition and processing for time-sensitive applications.

- Fault Tolerance and Redundancy:

- Features redundant architecture to maintain operation during component failures.

- Advanced alarm management for proactive fault detection and system recovery.

- Environmental Resilience:

- Designed for harsh industrial environments with temperature ratings up to 70°C.

- Robust construction to withstand vibration, shock, and EMI/RFI interference.

- Safety Certifications:

- Complies with international safety standards for use in hazardous locations (Class I, Div. 2).

- Complies with international safety standards for use in hazardous locations (Class I, Div. 2).

Application Scenarios

- Petrochemical Industry:

- Used in catalytic cracking and hydrocracking units for safety-critical control.

- Triggers emergency shutdowns to prevent explosions or leaks in high-risk processes.

- Power Generation:

- Manages boiler control, turbine synchronization, and grid stability in thermal and renewable energy plants.

- Ensures reliable operation of auxiliary systems in nuclear and fossil fuel power stations.

- Oil & Gas:

- Controls offshore platform operations, including wellhead pressure management and pipeline monitoring.

- Supports distributed control systems (DCS) for remote asset management.

- Pharmaceutical Manufacturing:

- Regulates sterile processing environments and batch reaction control.

- Maintains compliance with cGMP standards through precise parameter tracking.

- Water Treatment:

- Optimizes chemical dosing and aeration processes in wastewater treatment plants.

- Monitors water quality parameters for regulatory adherence.

Key Advantages

- High Reliability: Built-in redundancy and fault tolerance minimize downtime in mission-critical applications.

- Flexibility: Supports multiple control strategies to adapt to diverse process requirements.

- Safety Compliance: Certified for use in hazardous environments, reducing installation complexity.

- Scalability: Integrates seamlessly with Yokogawa’s CENTUM™ DCS and other industrial automation platforms.

- Global Support: Backed by Yokogawa’s worldwide service network for maintenance and technical assistance.

Reviews

There are no reviews yet.