Product Short Description

Technical Specifications

- Core Hardware:

- Processor: PowerPC 604e @ 333 MHz (industrial-grade RISC architecture) .

- Memory: 512 MB DDR2 SDRAM + 2 GB Flash storage .

- I/O Capacity: Supports 16 analog input channels, 16 analog output channels, and 32 digital I/O points (configurable) .

- Power Requirements: 24 V DC ±10%; Consumption: <50 W .

Description

- Physical & Environmental:

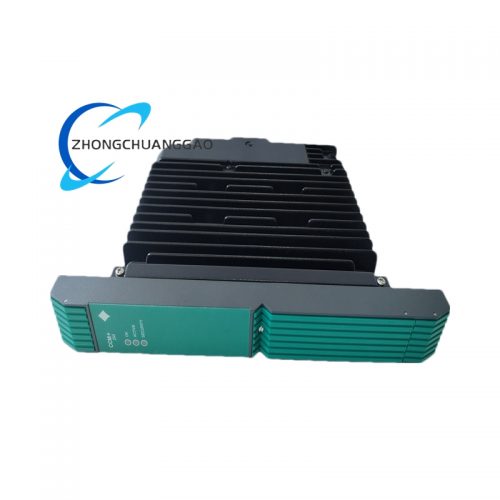

- Dimensions: 230 mm × 130 mm × 65 mm (9.06 in × 5.12 in × 2.56 in) .

- Weight: 1.5 kg (module); 2.0 kg (shipping weight) .

- Operating Temperature: -20°C to +70°C (industrial standard) .

- Protection Rating: IP20 (control cabinet use); IP54/66 variants for harsh environments .

- Communication Interfaces:

- Standard Protocols: PROFIBUS DP, Modbus TCP/IP, Ethernet/IP .

- Ports: Dual RJ-45 Ethernet (100 Mbps), RS-232, RS-485, CAN bus .

- Data Transfer: Real-time reflective memory for deterministic control .

Functional Features

- High-Performance Control:

- Executes IEC 61131-3-compliant logic (ladder, structured text, function blocks) for complex automation .

- Supports motion control protocols (PTP, electronic gearing) for servo-driven systems .

- Robustness & Reliability:

- Modular Hot-Swap: Replace modules without system shutdown .

- Self-Diagnostics: Front-panel LEDs for power, network, and fault status; 10,000+ event logs .

- Conformal Coating: Resists humidity/chemicals in harsh environments .

- Scalability & Integration:

- Expands via CEX-Bus to 128 Fieldbus Modules (FBMs) .

- Compatible with YOKOGAWA CENTUM VP, Experion PKS, and third-party PLCs (e.g., Siemens S7-1500) .

- Security & Compliance:

- SIL 2 functional safety certification .

- Password-protected firmware and encrypted data channels .

Application Scenarios

- Process Industries:

- Oil & Gas: Safety interlocks for refinery valve networks, pipeline pressure control .

- Chemical Plants: Batch reactor temperature/pressure management .

- Power Generation:

- Turbine governor control (integration with GE Mark VIe) .

- Grid load balancing and substation automation .

- Manufacturing Automation:

- Automotive: Robotic welding line synchronization (KUKA/PROFINET) .

- Pharmaceuticals: Precision filling machine control .

- Infrastructure:

- Water treatment plants: Pump station monitoring via Modbus RTU .

Compatibility & Ecosystem

- Hardware Integration:

- Controllers: CENTUM VP FCS, ABB AC 800M .

- I/O Modules: Analog (AAMxxx), Digital (ADMxxx), Fieldbus (FBM) series .

- Software Tools:

- Engineering Suite: CENTUM VP Configuration Tools for logic design .

- Diagnostics: Real-time health monitoring via Experion DCS .

Installation & Maintenance

- Deployment:

- Mounting: DIN rail (EN 60715) with ≥50 mm ventilation clearance .

- Cabling: Shielded twisted pairs; fiber-optic segregation for EMI immunity .

- Preventive Protocols:

- Biannual: Clean connectors, verify firmware updates .

- Annual: Calibrate analog I/O channels; test redundant power inputs .

- Troubleshooting:

- Boot Failure: Validate 24V DC stability; check capacitor health .

- Network Latency: Inspect RS-485 termination (120 Ω) .

Certifications & Support

- Compliance: CE, ATEX (Zone 2), RoHS, IEC 61131-2 .

- Warranty: 12–36 months (extendable) .

- Global Service: YOKOGAWA-certified engineers; 48-hour critical response .

Reviews

There are no reviews yet.