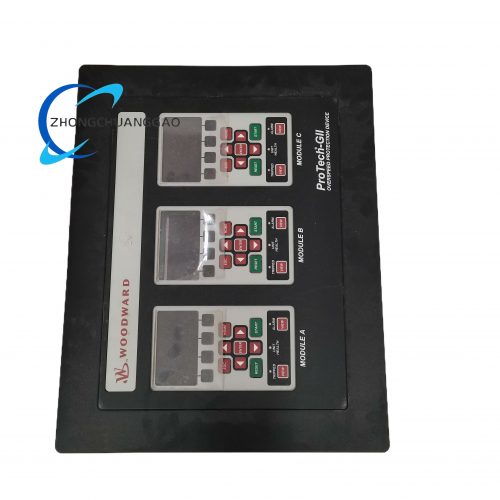

Product Short Description

Technical Specifications

-

Model: PEAK200-HVAC 8200-1501

-

Power Supply: 24 V DC (typical) or 115 / 230 V AC (configurable)

-

Processor: 32-bit microprocessor with real-time OS

-

I/O Points:

-

24 digital/analog inputs (temperature, pressure, speed sensors)

-

16 digital/analog outputs (valves, dampers, heaters)

-

Description

-

Communication:

-

Modbus RTU/TCP

-

BACnet MS/TP or IP

-

Woodward proprietary protocols

-

-

Display: Integrated 4-line graphical LCD or optional touchscreen

-

Enclosure: Panel-mount or bulkhead-mount, IP20 front

-

Dimensions: 26 mm W × 33 mm H × 37 mm D (controller board)

-

Weight: 26 kg (with enclosure and harness)

-

Power Consumption: 2.7 kW max @ 220 V AC, 50/60 Hz

-

Certifications:

-

UL 508

-

CE

-

Class 1 Div 2 / ATEX Zone 22 (explosion-proof variant)

-

Functional Features

-

Precise Speed Control: PID algorithms maintain turbine speed within ±0.1 % of set-point across load changes

-

Comprehensive Safety:

-

Overspeed trip with configurable set-points

-

Overpressure and overtemperature protection

-

Vibration monitoring and alarm

-

-

User-Friendly Interface: Menu-driven setup, real-time trend display, event logger (1000 entries)

-

Remote Monitoring: Web server and encrypted VPN tunnel for off-site diagnostics and tuning

-

Modular Expansion: Add-on I/O cards for extra sensors/actuators; supports redundant CPU for critical applications

Application Scenarios

-

HVAC Systems: Steam-driven chillers, absorption refrigerators, and district-heating turbo-compressors

-

Industrial Facilities: Petrochemical plants, refineries, and paper mills using small steam turbines for process drives

-

Energy & Power: Waste-heat recovery steam generators (HRSG), geothermal plants, and combined-cycle topping turbines

-

OEM Integration: Packaged turbine skids where compact, pre-configured control is required

.jpg)

Reviews

There are no reviews yet.