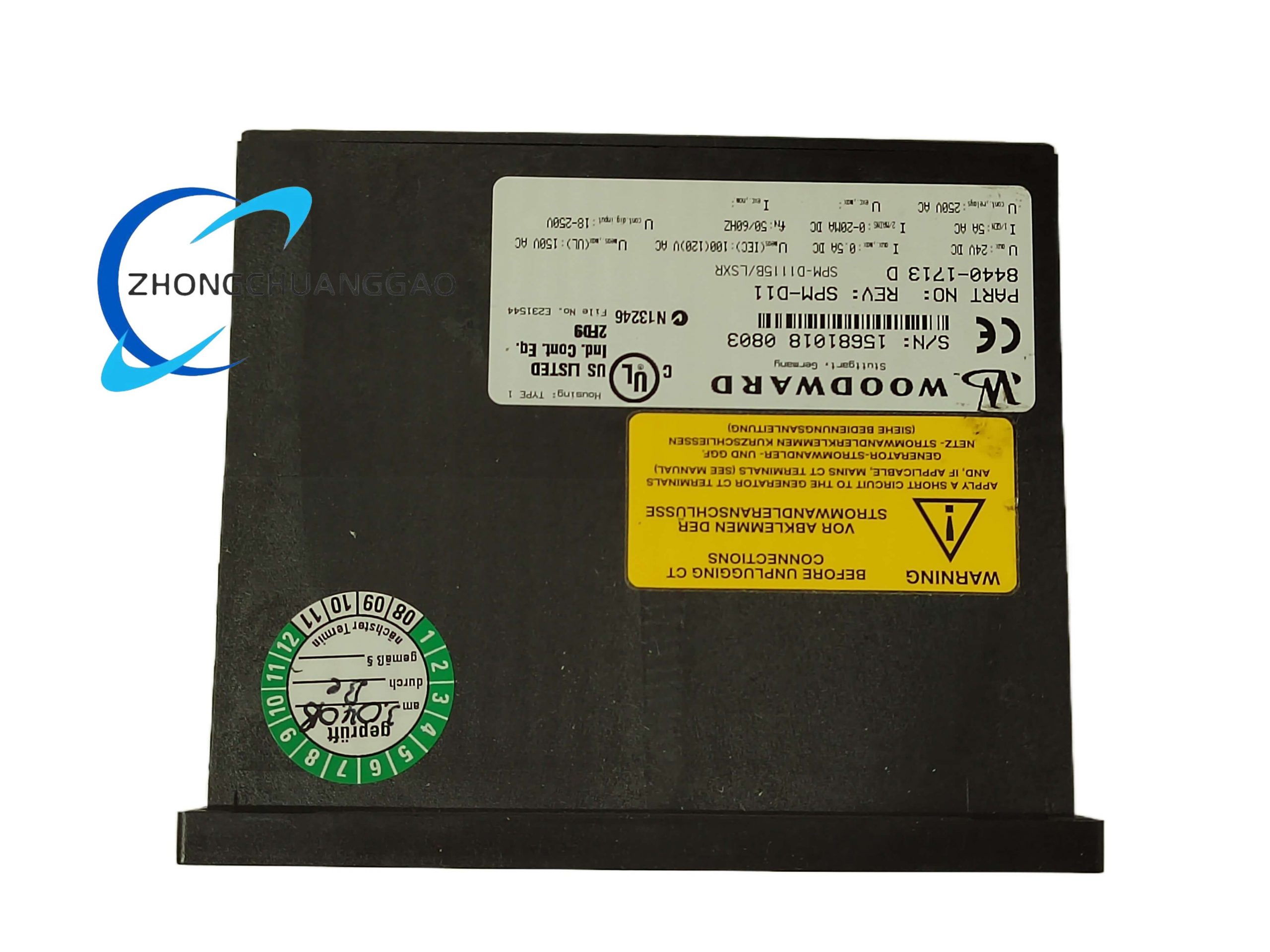

Product Short Description

Technical Specifications

- Dimensions: 140 mm (W) × 100 mm (H) × 80 mm (D)

- Weight: Approximately 0.5 kg

- Power Supply: 24 VDC (compatible with GE IC695ACC302 power modules)

- Power Consumption: 8 W (0.33 A at 24 VDC)

- Input Signals:

- 2 analog inputs (0–10 V/4–20 mA) for speed reference or sensor feedback

- 3 digital inputs for mode selection and emergency stop

- 1 RS485 port (Modbus RTU protocol)

- Output Signals:

- 1 analog output (0–10 V/4–20 mA) for driving actuators (e.g., fuel valves)

- 2 relay outputs for start/stop control and fault alarms

- 1 pulse output (1024 PPR encoder support) for speed feedback

Description

- Speed Range: 0–10,000 RPM (expandable to 50,000 RPM via parameter settings)

- Operating Temperature: -40°C to +70°C (storage: -55°C to +90°C)

- Humidity Tolerance: 5%–95% non-condensing

- Protection Class: IP40 (front panel)

- EMI Compliance: EN 61000-6-3

Key Features

- Multi-Mode Control:

- Closed-Loop Control: Uses PID algorithms with encoder feedback (1024 PPR) to achieve ±1.5 RPM accuracy at 1500 RPM, ideal for precision applications like medical equipment and test benches.

- Open-Loop Control: Relies on external speed signals (4–20 mA) for simpler systems like conveyors and fans, with ±0.5% accuracy.

- Load Adaptation: Detects sudden load changes (e.g., motor current spikes) and adjusts output within 50 ms to prevent speed drops (≤5 RPM deviation at 1500 RPM).

- Multi-Device Synergy: Seamlessly integrates with Siemens 6SE6440-2UD25-5CA1 inverters, Anchuan JAMSC-B2702V analog modules, and GE IC695ACC302 power supplies via Modbus RTU and RS485 interfaces.

- Diagnostics & Logging: Stores up to 50 fault events and 20 over-speed records with real-time timestamps for troubleshooting.

- Hot-Swappable Design: Modules can be replaced without powering down the system, reducing downtime.

Functional Highlights

- Speed Governance: Maintains stable generator speeds under fluctuating loads in power plants.

- Synchronization: Aligns phase and frequency for grid-connected or island microgrids.

- Startup Sequencing: Manages timed activation of auxiliary systems (e.g., lubrication pumps) during engine startups.

- Emergency Protection: Triggers fuel cutoff and mechanical braking within milliseconds upon detecting critical faults.

- Data Acquisition: Captures waveform data and trends for predictive maintenance.

Application Scenarios

- Power Generation: Controls generator speeds in thermal power plants, cogeneration units, and renewable energy systems (e.g., biomass, geothermal).

- Oil & Gas: Regulates centrifugal compressors and pump stations in production and transportation pipelines.

- Marine Propulsion: Manages main engine and auxiliary generator speeds on ships and offshore platforms.

- Industrial Automation: Optimizes motor speeds in manufacturing lines, mining equipment, and chemical processing plants.

- Transportation: Adjusts locomotive or generator set speeds for safe and efficient rail operations.

Advantages

- High Reliability: Designed for 24/7 operation in extreme conditions (vibration, shock, EMI).

- Scalability: Supports standalone systems or large-scale networks with hundreds of nodes.

- Ease of Integration: Compatible with third-party devices via Modbus RTU, reducing deployment complexity.

- Cost Efficiency: Minimizes downtime through proactive fault detection and remote diagnostics.

- Compliance: Meets international standards such as IEC 61508 SIL-2 and ATEX/IECEx for hazardous environments.

.jpg)

Reviews

There are no reviews yet.