Product Short Description

Technical Specifications

- Speed Control Range: 0 to 10,000 RPM (configurable via software for specific prime mover requirements)

- Input Signals:

- Speed input: Accepts magnetic pickup (MPU) signals (100 to 10,000 Hz) or proximity sensor signals

- Analog inputs: 2 x 4-20 mA (for load reference, remote setpoint, or process feedback)

- Digital inputs: 3 x dry contact (for start/stop, mode selection, or fault reset)

- Output Signals:

- Actuator output: 4-20 mA (for controlling fuel injectors, governor valves, or throttle actuators)

- Alarm outputs: 2 x Form C relay contacts (for high/low speed alarm, module fault)

- Accuracy: ±0.1% of set speed (steady-state condition)

Description

- Response Time: < 100 ms (for 90% settling of speed deviation)

- Power Supply: 18 to 32 VDC (regulated), 500 mA maximum current draw

- Operating Temperature: -40 °C to +70 °C

- Storage Temperature: -55 °C to +85 °C

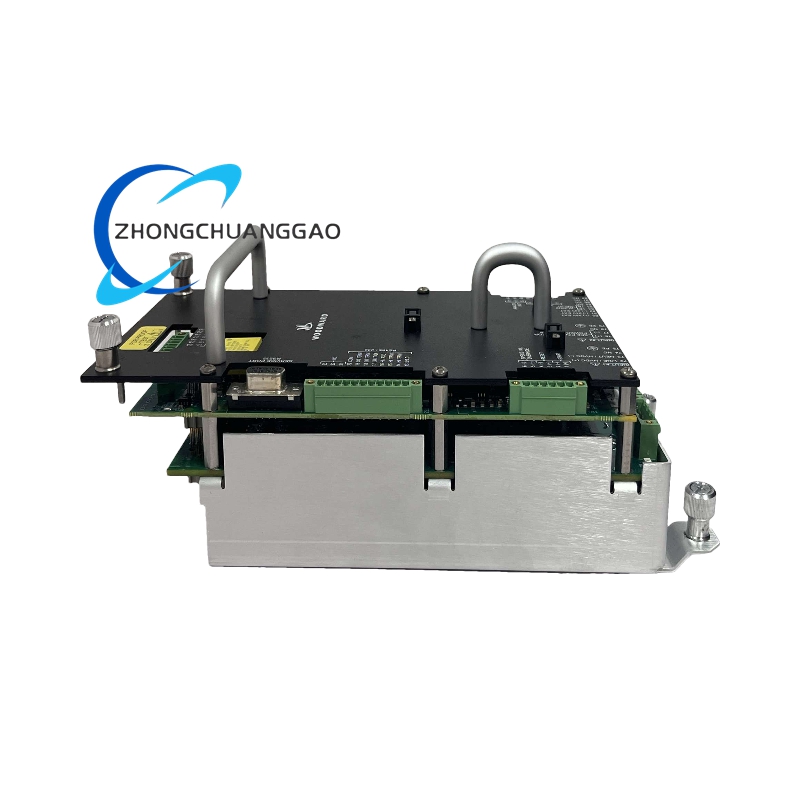

- Environmental Protection: IP20 (panel-mounted configuration); resistant to vibration (10-500 Hz, 2 g peak) and shock (50 g peak, 11 ms duration)

- Communication Protocol: Supports RS-485 (Modbus RTU) for configuration, monitoring, and data logging via Woodward’s dedicated software tool

Functional Features

- Precise Speed Regulation: Employs proportional-integral-derivative (PID) control algorithms with adaptive tuning, eliminating speed droop and maintaining consistent set speed even during sudden load changes (e.g., power grid fluctuations in turbine applications).

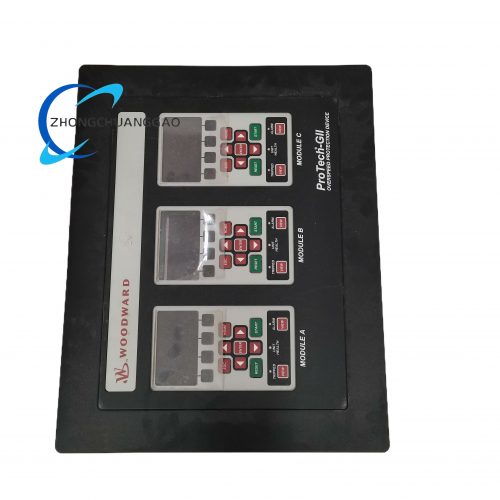

- Dual-Mode Operation: Supports both “Local” and “Remote” control modes. Local mode allows speed adjustment via front-panel potentiometer; Remote mode accepts external setpoint signals from plant DCS or SCADA systems.

- Built-in Protection Functions: Includes over-speed shutdown (programmable threshold), under-speed alarm, actuator current limiting, and module self-diagnostics (e.g., input signal loss, power supply fault) to prevent prime mover damage.

- Configurable Parameters: All critical settings (speed range, alarm thresholds, PID gains, input/output scaling) can be adjusted via software, eliminating the need for hardware modifications and enabling quick adaptation to different machinery.

- Data Logging & Monitoring: Records key operating data (speed, load, actuator position, fault codes) for up to 100 events, facilitating troubleshooting and preventive maintenance.

- Rugged Design: Constructed with industrial-grade components to withstand harsh operating environments (extreme temperatures, vibration, electrical noise) common in power generation, marine, and heavy industrial settings.

Application Scenarios

- Power Generation: Used in diesel generator sets (standby or prime power) and gas/steam turbine generators to maintain stable speed, ensuring consistent electrical output frequency (50/60 Hz) for grid connection or isolated load supply.

- Marine Industry: Integrated into marine diesel engines (main propulsion or auxiliary generators) to regulate speed during vessel navigation, ensuring smooth thrust control and reliable power for on-board systems.

- Oil & Gas Industry: Applied in gas turbine-driven compressors (for pipeline transmission or wellhead pressure control) and diesel-driven pumps (for crude oil transfer), maintaining precise speed to optimize process efficiency and safety.

- Heavy Industry: Utilized in industrial steam turbines (driving fans, pumps, or compressors) in steel, cement, and chemical plants, ensuring stable operation of critical process machinery.

- Locomotive & Off-Highway: Deployed in diesel engines for locomotives, mining trucks, and construction equipment, providing speed control to match load demands and improve fuel efficiency.

Be the first to review “Woodward 5437-1119” Cancel reply

Reviews

There are no reviews yet.