Product Short Description

- Technical Specifications

- Electrical Parameters

- Operating Voltage: It adopts a 24VDC power supply, which is consistent with the power supply specifications of most industrial field devices and ensures stable power input for its operation.

- Output Configuration: It is equipped with 16 commoned digital output points, which can meet the wiring connection needs of multi-channel digital output devices in general industrial scenarios.

- Electrical Protection: It is designed with electrical isolation performance, which can prevent electrical noise and external interference from affecting the stability of signal transmission between the module and field devices.

- Physical and Environmental Parameters

- Dimensions: The overall dimensions are 14.9cm × 5.3cm × 6.8cm, and its compact size allows it to be installed in control cabinets with limited space.

- Weight: It weighs approximately 0.56kg, which is lightweight and does not add excessive load to the installation structure.

- Operating Temperature Range: It can maintain normal operation within the range of -40°C to 85°C, adapting to the large temperature fluctuations of indoor and outdoor industrial sites.

- Installation Method: It adopts a panel-mounted installation design, which can be quickly fixed on the designated position of the industrial control panel to realize rapid deployment.

- Electrical Parameters

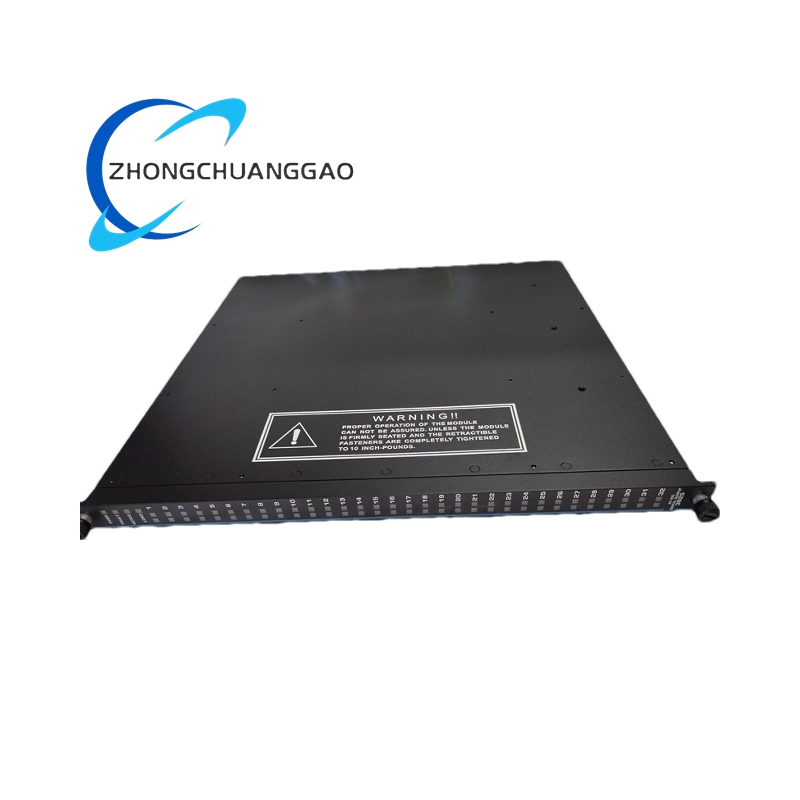

Description

- Functional Features

- Secure and Orderly Wiring Management: It provides a centralized termination point for field wiring of Triconex digital output modules. The clear terminal markings allow operators to connect wires accurately, avoid confusion caused by scattered wiring, and effectively reduce wiring errors during system installation.

- Strong System Compatibility: It achieves seamless compatibility with Tricon V9-V10 systems and various Triconex digital output modules. This compatibility enables it to be flexibly integrated into existing Triconex safety control systems without the need for additional adaptation accessories.

- Durable and Stable Structural Design: It adopts industrial-grade materials for its shell and internal components. The rugged structure can resist the erosion of dust, oil mist and other pollutants in industrial environments, and maintain stable performance during long-term continuous operation.

- Simplified Maintenance Operations: In addition to simplifying the initial wiring work, its standardized interface and clear marking also facilitate maintenance personnel to quickly locate the corresponding wiring points during later troubleshooting. It shortens the time for checking and replacing wires and reduces the downtime of the entire control system.

- Application Scenarios

- Oil and Gas Industry: It is widely used in oil drilling platforms and natural gas gathering and transportation stations. It is connected to the digital output modules of the Triconex safety system and field devices such as pipeline valves and pressure switches. It ensures the stable transmission of control signals between the system and the devices, and guarantees the reliable operation of emergency shutdown and other safety control functions when pipeline leakage or pressure abnormalities occur.

- Chemical Industry: It is deployed in chemical production workshops, especially in the control systems of chemical reactors and storage tanks. It connects the digital output signals of temperature, pressure and other detection equipment with the Triconex safety system. When the process parameters exceed the safety threshold, it ensures that the system can send control signals to the actuators smoothly to trigger protective measures such as feeding interruption.

- Power Generation Industry: It is applied to the safety control systems of thermal power plants and hydropower stations. It is used in the wiring connection between the digital output modules of the generator, turbine and other key equipment control systems and the on-site executive components. It ensures the timely transmission of start-stop, speed regulation and other control signals, and maintains the stable operation of the power generation equipment.

- Petrochemical Industry: It is integrated into the refining process control system of refineries. It cooperates with Triconex digital output modules to connect with various valves, pumps and other equipment on the refining production line. It ensures the accurate transmission of control signals in each refining link, and avoids production accidents caused by signal transmission failures.

- Pharmaceutical Industry: It is used in the automated production lines of pharmaceutical factories that adopt Triconex safety systems. It is involved in the wiring connection of digital output signals of equipment such as pharmaceutical reaction kettles and sterile conveying devices. It ensures the stable operation of the production process and meets the strict safety and hygiene standards of the pharmaceutical industry.

Be the first to review “Triconex 9662-810 Digital Output Termination Panel” Cancel reply

Reviews

There are no reviews yet.