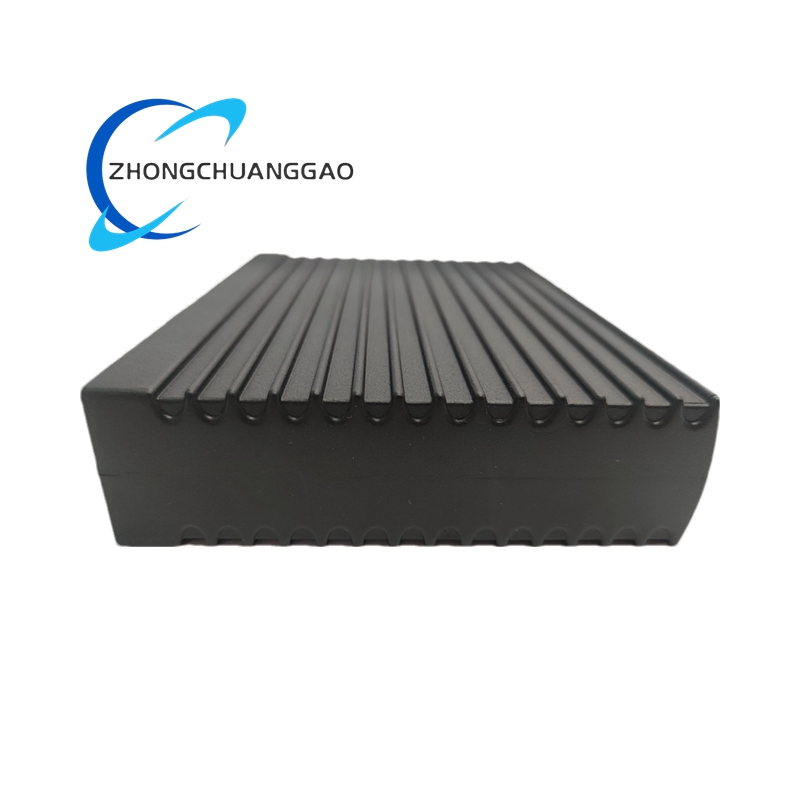

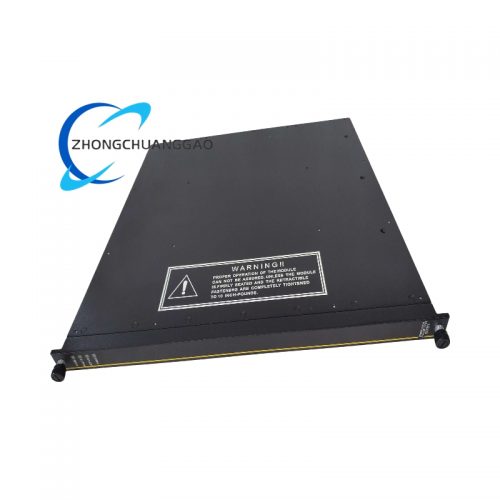

Product Short Description

Technical Specifications

- Communication Parameters

- Supported Protocols: It is compatible with multiple mainstream industrial communication protocols including Modbus TCP/IP, Ethernet/IP, RTU, RS-232 and RS-485, realizing smooth data exchange with different industrial devices and systems.

- Maximum Communication Distance: It can stably connect I/O modules 1000 meters away from the controller, satisfying the connection needs of remote equipment in large industrial sites.

- I/O Channel Capacity: It is configured with 32 individually isolated output channels, and supports the expansion of various I/O types such as digital input, analog input, digital output and analog output.

- Electrical and Physical Parameters

- Power Supply: It uses a 24V DC power supply, with an input voltage range of 18V DC to 32V DC, which is compatible with the power supply system of common industrial control cabinets.

- Power Consumption: Its typical power consumption is less than 8.0W, which has low energy consumption and reduces the overall power load of the control system.

- Installation Method: It is designed for installation in a Triconex chassis and also conforms to DIN rail mounting standards, adapting to standard industrial installation requirements.

- Isolation Performance: It has channel-to-channel and channel-to-system isolation capabilities, which can effectively prevent signal interference between different channels and ensure the accuracy of data transmission.

Description

-

- Environmental Parameters

- Operating Temperature: It can maintain stable operation within the range of -40°C to 70°C, adapting to extreme temperature conditions in both indoor control cabinets and outdoor industrial sites.

- Storage Temperature: The safe storage temperature range is -40°C to 85°C, meeting the requirements of long-term storage and long-distance transportation under various climate conditions.

- Humidity Adaptability: It can work normally under the condition of 10% to 95% relative humidity without condensation, which is suitable for high-humidity environments such as coastal industrial areas and chemical workshops.

- Anti-interference Performance: It has strong resistance to shock and vibration, and can maintain stable performance without being affected by the operation of large industrial machinery.

- Environmental Parameters

- Functional Features

- TMR Architecture for High Reliability: The triple modular redundancy architecture is adopted to ensure that the system can still maintain continuous and normal operation when a single module fails. This design fundamentally avoids safety accidents and production interruptions caused by single-point faults, and meets the high-reliability requirements of critical industrial processes.

- Convenient Hot-swappable Maintenance: It supports hot-swappable operation. When the module needs maintenance or replacement, it can be removed and installed without shutting down the entire control system. This greatly shortens the system downtime and improves the operational availability of the industrial production line.

- Comprehensive Real-time Diagnostic Capabilities: It is equipped with perfect fault diagnosis functions, which can conduct real-time monitoring on the output integrity and the health status of the module itself. It can quickly detect faults such as line virtual connections and disconnections, and feed back fault information to the main control system in a timely manner to facilitate maintenance personnel to locate and solve problems quickly.

- Flexible Configuration and Expansion: Users can customize the output logic according to actual application needs to adapt to different control scenarios. At the same time, it can be flexibly integrated with other Triconex modules, and can expand up to multiple I/O modules, which can meet the I/O expansion needs of control systems of different scales.

- Strong System Compatibility: It can be perfectly integrated with the Triconex safety control system and is also compatible with a variety of industrial control equipment such as mainstream PLCs and HMIs. It can be smoothly connected to existing industrial automation systems without large-scale transformation of the original system.

- Application Scenarios

- Oil and Gas Industry: It is widely used in oilfield exploitation, refineries and natural gas processing plants. It connects the Triconex main control system with remote flowmeters, pressure sensors and pipeline emergency shutdown valves. It realizes real-time transmission of data such as oil extraction volume and natural gas processing pressure, and ensures that the emergency system can quickly respond to pipeline leakage and other dangerous situations.

- Chemical Industry: It is deployed in chemical production lines, chemical mixing workshops and reactor control systems. It connects the central safety controller with remote toxic gas detectors, reaction kettle temperature sensors and material delivery control valves. It monitors the key parameters of the chemical reaction process in real time and triggers corresponding safety interlocking measures immediately when abnormalities occur to avoid explosion and leakage accidents.

- Power Industry: It plays an important role in power plants, substations and power distribution systems. It is responsible for connecting the Triconex safety control system with remote generators, transformers and switchgear monitoring devices. It realizes the real-time monitoring of parameters such as generator load and transformer temperature, and guarantees the safe and stable operation of the power supply system.

- Manufacturing Industry: It is integrated into automated production lines of automobile manufacturing, electronic component processing and other fields. It connects the main control system with remote robotic arms, assembly line conveying devices and product quality inspection sensors. It realizes the precise control of each link of the production line and improves production efficiency while ensuring product quality.

- Transportation Industry: It is applied to rail transit and aerospace ground support equipment. In rail transit systems, it connects the central control system with remote track state sensors and signal devices. It ensures the real-time transmission of signal and track state data, and provides a reliable guarantee for the safe operation of trains.

Be the first to review “Triconex 4211 TMR Remote I/O Extender Module” Cancel reply

Reviews

There are no reviews yet.