Product Short Description

Technical Specifications

- Electrical Parameters

- Input Channels: Equipped with 32 independent digital input channels, each channel is designed with a triple modular redundancy structure to ensure signal collection accuracy and fault tolerance.

- Input Voltage: Compatible with the industrial universal 24 VDC voltage, which can perfectly match most digital sensors and switching devices on the market.

- Response Time: The typical response time of the input signal is less than 3 ms, which can quickly capture transient abnormal signals on the industrial site and provide a timely data basis for the safety interlock actions of the system.

- Isolation Performance: The isolation voltage between channels is 1500 VAC, and the isolation voltage between channels and the ground is 2500 VAC, which can effectively isolate electromagnetic interference between different circuits and avoid signal errors caused by interference.

- Power Consumption: Each channel has a typical power consumption of 8 mA under 24 VDC working conditions, and the low-power design reduces the overall energy consumption pressure of the control system.

Description

-

- Physical Parameters

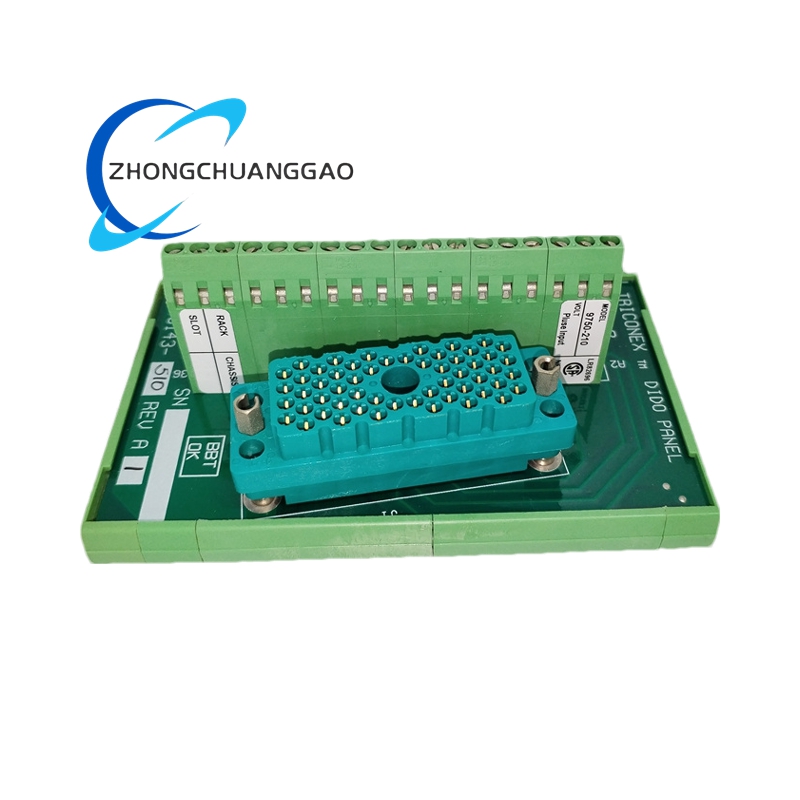

- Dimensions: Adopts a compact design with dimensions of 175 mm × 120 mm × 50 mm, which is fully compatible with Triconex standard system chassis and saves the installation space of the control cabinet.

- Weight: The net weight is about 1.4 kg. The metal shell design enhances the module’s resistance to mechanical impact and ensures structural stability during transportation and installation.

- Connector Type: Equipped with a 50-pin detachable terminal block, which simplifies on-site wiring operations and enables quick disassembly and assembly during later maintenance.

- Environmental Parameters

- Operating Temperature: It can operate stably in the range of -40°C to 70°C, adapting to extreme temperature environments such as indoor control rooms and outdoor oil fields.

- Storage Temperature: The safe storage temperature range is -55°C to 85°C, which can maintain stable performance during long-term storage and long-distance transportation.

- Humidity Resistance: It can work normally in an environment with a relative humidity of 5% – 95% without condensation, which is suitable for humid industrial environments such as coastal chemical plants.

- Vibration Resistance: It can withstand 2 g vibration in the frequency range of 10 Hz – 500 Hz, and can be installed on equipment with continuous vibration such as industrial pumps and compressors.

- Physical Parameters

- Functional Features

- Triple Modular Redundancy Ensures Operational Stability: Three independent circuit paths collect and verify the signals of each input channel at the same time. The upper controller uses a two-out-of-three voting mechanism to determine the final signal state. Even if one or two circuit paths fail, the module can still output accurate signals, completely eliminating the impact of single-point faults on the system.

- Hot-Swap Function Reduces Production Downtime: The module supports hot-swapping operation in the Triconex system. Maintenance personnel can replace the faulty module without shutting down the entire safety system, which greatly shortens the maintenance time, minimizes production losses caused by system shutdown, and improves the availability of the production line.

- Comprehensive Diagnostic Capabilities Simplify Maintenance: Each input channel is equipped with an independent diagnostic circuit, which can monitor the wiring status of the channel and the working status of the connected equipment in real time. When faults such as open circuits and poor contact occur, the fault information will be uploaded to the upper system immediately, and the corresponding indicator lights on the module will light up to help maintenance personnel quickly locate and solve problems.

- Strong Compatibility Realizes Seamless Integration: It can be perfectly compatible with Triconex Tricon and Tricon CX series controllers. During system integration, there is no need to modify the core program of the controller, and plug-and-play can be achieved. It can also be matched with the standard accessories of the Triconex system, which simplifies the system debugging process.

- Fast Signal Response Supports Timely Interlock: The ultra-fast response time of less than 3 ms allows the module to capture abnormal signals such as sudden equipment failures in time. This enables the safety system to trigger emergency measures such as shutdown and alarm quickly, preventing minor faults from evolving into major safety accidents.

- Application Scenarios

- Oil and Gas Industry: Deployed in emergency shutdown systems and fire and gas systems of offshore drilling platforms and onshore oil pipelines. It collects signals from pipeline pressure sensors and gas detectors. When overpressure or gas leakage is detected, it can quickly send signals to the controller to trigger pipeline shutdown and fire-fighting equipment startup, avoiding explosions and other serious accidents.

- Petrochemical Industry: Installed in the safety interlock systems of chemical reactors, distillation towers, and storage tanks. It collects signals from temperature sensors and liquid level switches in the equipment. When the temperature or liquid level exceeds the safe threshold, it can transmit data to the upper system in time to cut off the feeding or heating system and prevent dangerous situations such as material leakage and chemical reactions out of control.

- Power Generation Industry: Applied to the safety control systems of thermal power plants and nuclear power plant auxiliary equipment. It collects signals from steam turbine overspeed sensors and boiler safety valve position switches. When the unit has abnormal operation, it can quickly feed back the fault information, ensuring that the system can adjust the equipment state in time to protect the safety of key power generation equipment.

- Metallurgical Industry: Integrated into the safety control systems of blast furnaces and continuous casting equipment. It collects signals from furnace temperature sensors and cooling water flow switches. When the furnace temperature is too high or the cooling water flow is insufficient, it can immediately send a signal to the controller to adjust the production parameters, avoiding equipment damage caused by overheating.

- Pharmaceutical Industry: Used in automatic production lines such as high-temperature sterilization and precision filling of drugs. It collects signals from photoelectric sensors and pressure switches on the production line. It ensures that each link of drug production meets GMP standards and avoids batch drug quality problems caused by abnormal equipment operation.

Be the first to review “Triconex 4000189-530 32-Channel Triple Modular Redundancy Digital Input Module” Cancel reply

Reviews

There are no reviews yet.