Product Short Description

Technical Specifications

Electrical Parameters

Operating Voltage: It operates on a 220V AC power supply, which matches the power supply specifications of most industrial control cabinets and can be directly integrated into existing power supply systems of industrial sites without additional voltage conversion equipment.

Synchronization Performance: The three processor channels of the triple modular redundancy architecture maintain 0.5ms synchronization, ensuring real-time consistency of data processing across channels and avoiding control errors caused by data asynchrony.

Mechanical Parameters

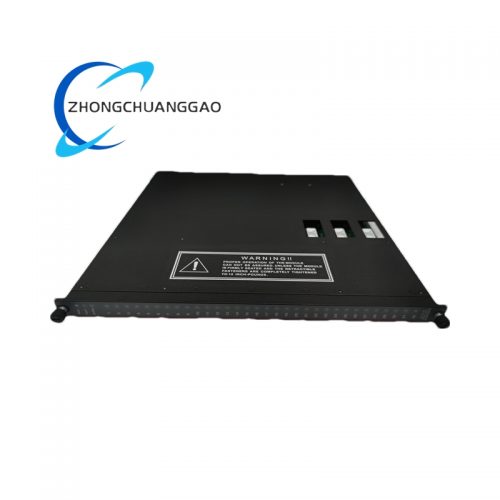

Installation Design: It adopts a 19-inch rack-mount design. This compact structure saves a lot of space in the control panel compared with previous generations of products, facilitating centralized installation and layout with other control modules in the cabinet.

Structural Feature: It has no moving parts in its internal structure, which fundamentally reduces mechanical wear and tear during long-term operation and prolongs the service life of the product.

Reviews

There are no reviews yet.