Product Short Description

Technical Specifications

- Physical Parameters

The weight of the module without packaging is 353 grams, and the weight including packaging reaches 493 grams. Its compact size matches the standard rack structure of Triconex systems. It can be installed in the control cabinet without occupying excessive space, and facilitates flexible combination with other modules in the system.

- System Compatibility

It achieves full compatibility with the entire series of Triconex control systems. It can form a complete signal transmission and control loop with the system’s logic solvers, I/O modules and other components. It also adapts to the connection requirements of third – party industrial devices, and only needs to comply with the safety specifications and warning instructions of third – party manufacturers during use.

- Certification and Compliance

It has obtained CE and ISO certifications, meeting strict international industrial product quality and safety standards. It is compatible with the safety design requirements of Triconex safety instrumented systems, and helps the overall system meet the operational standards of safety – related industrial scenarios.

Description

-

- Installation Standards

It follows standardized industrial installation guidelines. The installation process must comply with the specified installation instructions to ensure the stability of its connection with the system and field devices. The terminal interface design matches the common wiring specifications in industrial fields, which simplifies the on – site wiring operation.

- Installation Standards

- Functional Features

- Dual – role Integration

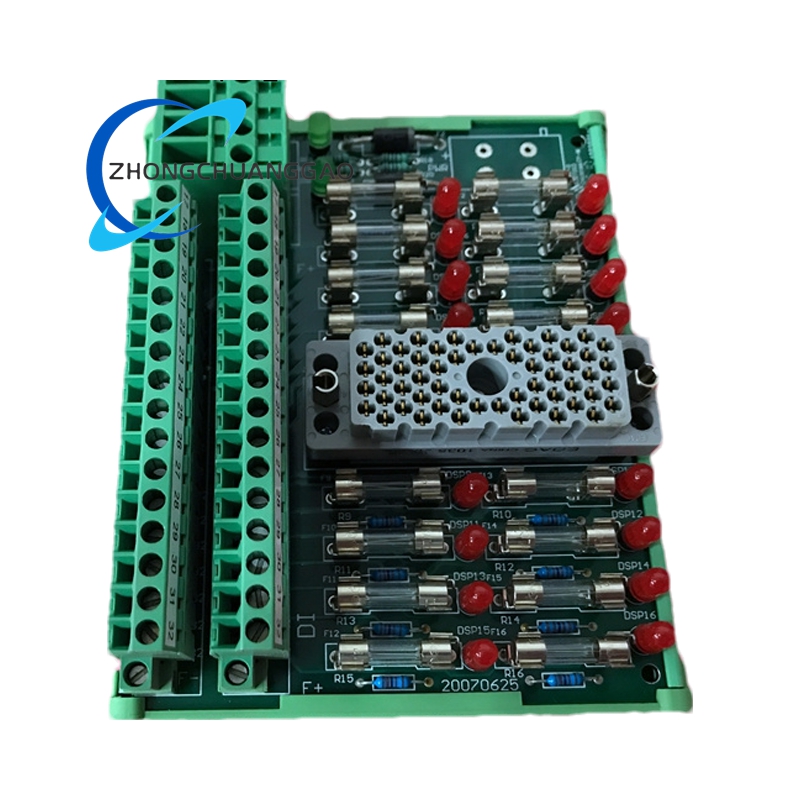

It combines the functions of a contact termination board and an interface module. It not only provides stable physical wiring terminals for field devices to avoid poor contact and other problems, but also realizes smooth communication and data exchange between different devices in the industrial automation system. It integrates two key functions and reduces the need for additional connecting components.

- Fault – tolerant Collaboration

It works with the Triconex system’s triple modular redundancy architecture. When individual minor connection or signal transmission problems occur, it can cooperate with the system’s fault – tolerant mechanism to maintain normal data transmission and control functions. It avoids overall system downtime caused by local small faults and improves the reliability of the entire system.

- Simplified System Maintenance

Its standardized structural design and clear terminal identification facilitate maintenance personnel to quickly locate the wiring position during daily inspection. When the system needs to be maintained or modified, it can be disassembled and assembled quickly without affecting the normal operation of other core modules, which shortens the maintenance time.

- Stable Signal Transmission

The Phoenix contact design adopted by the module ensures tight connection with wires. It reduces signal loss and interference during transmission. It ensures that the on – site equipment status signals can be accurately transmitted to the main control system, and the control instructions issued by the main control system can be efficiently executed by the on – site equipment.

- Dual – role Integration

- Application Scenarios

- Oil and Gas Industry

It is widely used in oil drilling platforms and natural gas pipeline stations. It connects the signal lines of on – site pressure sensors, flow meters and emergency shut-off valves to the Triconex emergency shutdown system. It ensures that the system can receive abnormal signals in a timely manner and trigger corresponding protective measures to prevent safety accidents such as pipeline leakage and explosion.

- Petrochemical Industry

In petrochemical plants, it is deployed in the safety control systems of devices such as reaction kettles and distillation towers. It undertakes the wiring and signal transmission tasks between temperature and concentration sensors on the equipment and the Triconex DCS system. It ensures the stable transmission of process parameters and helps the system adjust process indicators in real time to avoid fire and explosion caused by abnormal parameters.

- Power Generation Industry

It is applied to the safety control systems of thermal power and nuclear power plants. It connects the signal lines of boiler water level sensors, steam pressure detectors and turbine speed monitors to the Triconex safety system. It ensures that the system can quickly respond to equipment abnormalities and implement load reduction or emergency shutdown measures to protect the safe operation of power generation equipment.

- Mining Industry

It is used in the automatic control systems of mining sites. It connects the signal lines of equipment such as mining machinery operation status detectors and underground gas concentration sensors to the Triconex control system. It realizes real – time monitoring of the operation status of mining equipment and the underground environment. It ensures that relevant personnel can take shutdown and evacuation measures in time when dangerous situations occur.

- Oil and Gas Industry

Reviews

There are no reviews yet.