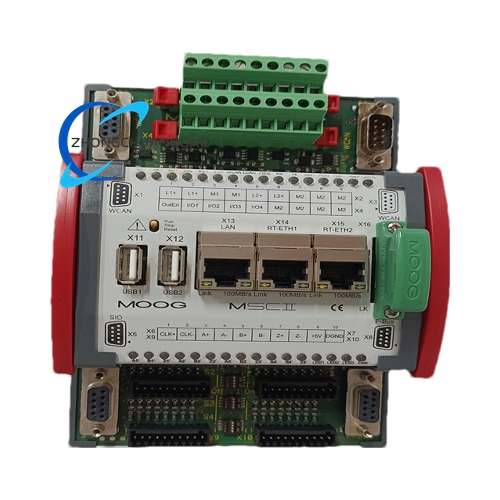

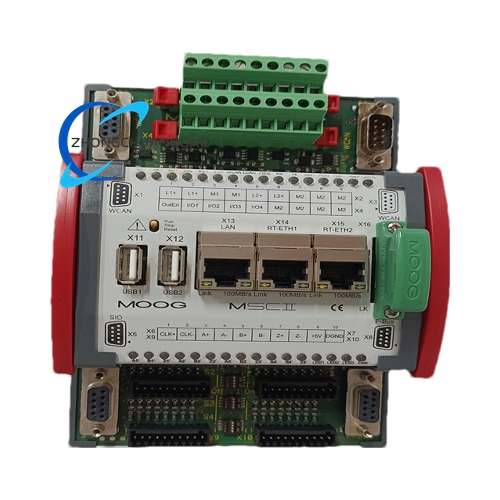

Description

2. Technical Specifications

• Power supply: 24 VDC (18–36 V), SELV/PELV, 0.5 A no-load / 2 A full-load

• Processor: 32-bit PowerPC RISC with FPU, 400 MHz

• Memory: 128 MB SDRAM, 32 MB Flash EEPROM (data retention ≥ 10 years)

• Control cycle: minimum 100 µs base tick, I/O update synchronous with base tick

• Position feedback: 4 × universal encoder interfaces, each configurable for

– Incremental TTL/HTL up to 8 MHz (4-edge evaluation)

– SSI absolute, 8–32 bit, 78 kHz – 5 MHz clock

• On-board I/O:

– 4 × digital I/O, individually configurable as in or out, 24 VDC, 0.5 A per channel, short-circuit proof

– 2 × analog input, ±10 V or 4–20 mA, 16-bit

– 2 × analog output, ±10 V or 4–20 mA, 16-bit

• Communication:

– Ethernet 10/100 Mbit RJ45 for programming, TCP/IP, UDP/IP, remote service

– 2 × CAN/CANopen, 10 kbit/s – 1 Mbit/s

– RS-232 service port (front), RS-485 isolated (side)

– Expansion bus (E-Bus) for up to seven additional modules

– Optional PROFIBUS-DP slave or EtherCAT master/slave via plug-on modules

• Mechanical: 160 × 170 × 85 mm (W×D×H), DIN-rail EN 50022 NS 35/7.5, IP20

• Environment: operating −20 °C to +70 °C, storage −25 °C to +70 °C, 10–95 % RH non-condensing, 2000 m altitude

• Standards: IEC 61131-2, EN 61000-6-2/4, IEC 60068-2-27 shock, IEC 60068-2-6 vibration

• Power supply: 24 VDC (18–36 V), SELV/PELV, 0.5 A no-load / 2 A full-load

• Processor: 32-bit PowerPC RISC with FPU, 400 MHz

• Memory: 128 MB SDRAM, 32 MB Flash EEPROM (data retention ≥ 10 years)

• Control cycle: minimum 100 µs base tick, I/O update synchronous with base tick

• Position feedback: 4 × universal encoder interfaces, each configurable for

– Incremental TTL/HTL up to 8 MHz (4-edge evaluation)

– SSI absolute, 8–32 bit, 78 kHz – 5 MHz clock

• On-board I/O:

– 4 × digital I/O, individually configurable as in or out, 24 VDC, 0.5 A per channel, short-circuit proof

– 2 × analog input, ±10 V or 4–20 mA, 16-bit

– 2 × analog output, ±10 V or 4–20 mA, 16-bit

• Communication:

– Ethernet 10/100 Mbit RJ45 for programming, TCP/IP, UDP/IP, remote service

– 2 × CAN/CANopen, 10 kbit/s – 1 Mbit/s

– RS-232 service port (front), RS-485 isolated (side)

– Expansion bus (E-Bus) for up to seven additional modules

– Optional PROFIBUS-DP slave or EtherCAT master/slave via plug-on modules

• Mechanical: 160 × 170 × 85 mm (W×D×H), DIN-rail EN 50022 NS 35/7.5, IP20

• Environment: operating −20 °C to +70 °C, storage −25 °C to +70 °C, 10–95 % RH non-condensing, 2000 m altitude

• Standards: IEC 61131-2, EN 61000-6-2/4, IEC 60068-2-27 shock, IEC 60068-2-6 vibration

3. Functional Highlights

• IEC 61131-3 programming with Moog Axis Control Software (MACS): ladder, structured text, function block, SFC

• Pre-engineered Moog motion libraries for hydraulic positioning, camming, gearing, force/pressure control

• Integrated PLCopen motion function blocks shorten commissioning time

• Hot-plug CompactFlash for program and data storage; firmware upgrade via Ethernet or USB memory stick

• Watchdog output and comprehensive diagnostics (LED, web server, SNMP)

• Remote debugging and firmware update over Ethernet

• IEC 61131-3 programming with Moog Axis Control Software (MACS): ladder, structured text, function block, SFC

• Pre-engineered Moog motion libraries for hydraulic positioning, camming, gearing, force/pressure control

• Integrated PLCopen motion function blocks shorten commissioning time

• Hot-plug CompactFlash for program and data storage; firmware upgrade via Ethernet or USB memory stick

• Watchdog output and comprehensive diagnostics (LED, web server, SNMP)

• Remote debugging and firmware update over Ethernet

4. Application Scenarios

• Industrial robotics: multi-axis Cartesian, SCARA, delta robots

• Precision machining: CNC feed drives, grinding, honing, broaching machines

• Hydraulic presses and injection molding machines requiring force/position control

• Packaging and converting lines: flying shear, cross-cut, print registration

• Test rigs: automotive component durability, aerospace actuators

• Wind and hydro turbine pitch control systems

• Industrial robotics: multi-axis Cartesian, SCARA, delta robots

• Precision machining: CNC feed drives, grinding, honing, broaching machines

• Hydraulic presses and injection molding machines requiring force/position control

• Packaging and converting lines: flying shear, cross-cut, print registration

• Test rigs: automotive component durability, aerospace actuators

• Wind and hydro turbine pitch control systems

5. Ordering & Expansion

• Standard delivery: D136-002-005 controller, MACS license key, terminal plugs, DIN-rail end clamp

• Expansion modules (snap-on via E-Bus):

– QAIO 16/4-A, QAIO 16/4-V additional analog I/O

– QDIO 16/16-0.5N high-density digital I/O

– QEBUS-CAN gateway for external CAN nodes

• Optional PROFIBUS-DP slave or EtherCAT master/slave cartridges

• MACS software licenses: single seat or team packs; annual maintenance contracts available

• Standard delivery: D136-002-005 controller, MACS license key, terminal plugs, DIN-rail end clamp

• Expansion modules (snap-on via E-Bus):

– QAIO 16/4-A, QAIO 16/4-V additional analog I/O

– QDIO 16/16-0.5N high-density digital I/O

– QEBUS-CAN gateway for external CAN nodes

• Optional PROFIBUS-DP slave or EtherCAT master/slave cartridges

• MACS software licenses: single seat or team packs; annual maintenance contracts available

Reviews

There are no reviews yet.