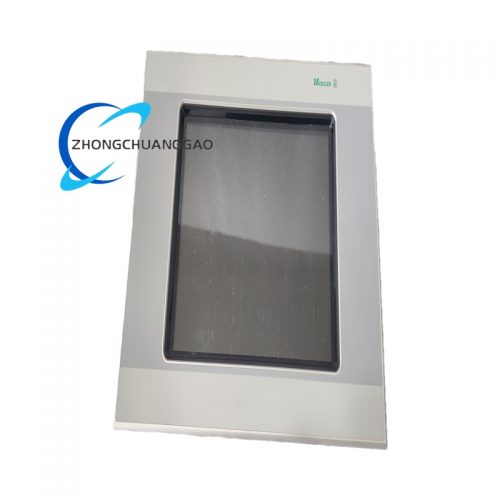

Product Short Description

Technical Specifications

- Electrical Parameters

- Voltage Requirements: It has a stable output voltage of 24VDC and an input voltage range of 18VDC to 30VDC, while also being compatible with a 220V power supply configuration to adapt to different industrial power supply environments.

- Control Inputs: It supports various control input signal types including 24VDC, 0 – 10V and 4 – 20mA, which can match different types of sensors and control signal sources in industrial systems.

- Output and Communication: Its output frequency reaches 30kHz. It is equipped with Ethernet, Profibus and CANopen communication interfaces to realize fast and stable data transmission and signal interaction with other automation equipment.

- Physical Parameters

- Dimensions and Weight: It has dimensions of 16.7cm×14.8cm×5.5cm and a weight of 0.6kg. The lightweight and small size characteristics make it convenient for installation and arrangement without occupying excessive space in the equipment.

- Protection Level: It achieves an IP67 protection level, which can fully prevent the entry of dust and resist the erosion of water immersion in short time or under certain pressure, adapting to complex and harsh on-site working conditions.

Description

-

- Environmental Parameters

- Operating Temperature: It can maintain stable operation within the operating temperature range of -20°C to +60°C, adapting to the temperature changes of indoor and outdoor industrial sites in different regions.

- Storage Temperature: Its storage temperature range is -30°C to +80°C, and it can withstand a non-condensing humidity range of 10% to 95%, which provides great convenience for long-term storage and transportation in different regions.

- Environmental Parameters

-

Function Features

- Accurate Robot Motion Control: The module is specially designed for KUKA robot systems and can precisely control the motion trajectory and posture of robots. It ensures that the robot can complete actions such as grabbing, assembling and transferring with high precision, which lays a foundation for improving the consistency and qualification rate of product processing and assembly.

- Strong Environmental Adaptability: With the IP67 protection level and wide temperature and humidity adaptation ranges, it can operate stably in various harsh industrial environments such as workshops with serious dust pollution, processing sites with frequent water splashing and outdoor operation areas with large temperature differences, without being easily affected by the environment to cause performance degradation.

- Seamless System Integration: It supports multiple mainstream communication protocols including Ethernet, Profibus and CANopen. These abundant communication interfaces enable it to quickly connect with other control modules, sensors, actuators and upper computer systems in the automated production line, realizing seamless integration without large-scale transformation of the original system.

- Efficient and Reliable Operation Performance: The adoption of high-grade electronic components and sophisticated manufacturing processes ensures its long-term reliable operation in high-intensity continuous production. It reduces the failure rate of the robot control system, minimizes the downtime of the production line caused by module faults, and effectively maintains the continuity of industrial production.

-

Application Scenarios

- Automotive Manufacturing Assembly Lines: It is widely used in KUKA robot systems on automotive component assembly lines. It controls robots to complete precise operations such as welding of auto bodies, installation of engines, and assembly of electrical components. It ensures the accuracy and efficiency of each assembly step and promotes the high-speed operation of the automotive assembly line.

- Electronics Production and Processing: In electronic component manufacturing workshops, it controls small and medium-sized KUKA robots to carry out tasks such as chip mounting, circuit board welding and precision component transfer. Its high-precision control capability ensures that fragile electronic components are not damaged during processing and assembly, and improves the production yield of electronic products.

- General Machinery Processing Workshops: It is applied to KUKA robots in machinery processing fields such as metal cutting and stamping. It controls the robot to cooperate with CNC machine tools to complete the loading and unloading of workpieces, the transfer between multiple processes and other operations. It reduces manual intervention, shortens the processing cycle of workpieces and improves the overall production efficiency of the workshop.

- Logistics and Warehousing Automation Systems: In intelligent logistics warehouses, it is integrated into KUKA AGV and handling robot systems. It controls the robots to accurately grab, sort and transport goods, and cooperates with the warehouse management system to realize the automatic operation of the whole process from goods in warehouse to delivery, improving the turnover efficiency of goods in the warehouse.

- Aerospace Component Processing: In the field of aerospace manufacturing, it controls KUKA precision robots to process and assemble high-precision aerospace components. Its high stability and precision control can meet the strict quality requirements of aerospace components, which is crucial to ensuring the safety and reliability of aerospace equipment.

Be the first to review “KUKA DSE-IBS 3.02 High-Precision Industrial Robot Motion Control Module” Cancel reply

-500x500.jpg)

Reviews

There are no reviews yet.