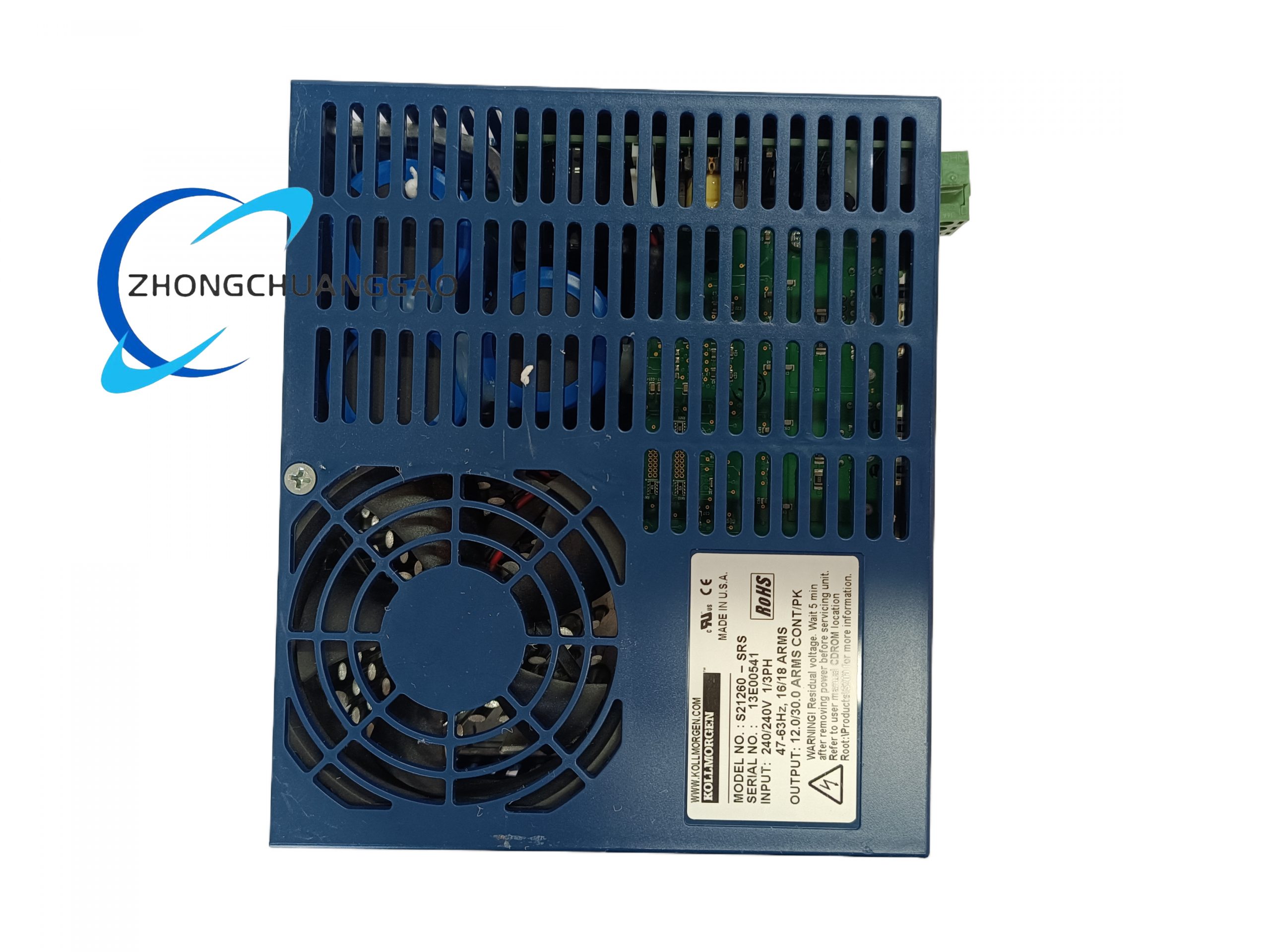

Product Short Description

Technical Specifications

- Input Voltage: Supports 120 VAC or 240 VAC single-phase/three-phase input.

- Continuous Current Rating: 12 ARMS (root mean square).

- Peak Current Rating: 18 ARMS.

- Output Power:

- 10,000 VA for 1 second at 240 VAC (three-phase).

- 8,000 VA for 1 second at 240 VAC (single-phase).

- Speed Loop Bandwidth: Up to 800 Hz for rapid dynamic response.

- Feedback Resolution: 24-bit high-resolution encoder feedback for sub-micron positioning accuracy.

- Communication Interfaces:

- Pre-installed SynqNet option card with standard RJ connectors.

- Optional EtherCAT or CANopen for real-time networking.

- Environmental Rating: IP20 protection for dust and liquid resistance.

- Operating Temperature: Continuous convection rating of 12.0 ARMS at 40°C ambient, 8.0 ARMS at 50°C ambient.

Description

Key Features

- High-Precision Control:

- Advanced servo algorithms ensure precise speed, position, and torque regulation.

- Sub-millisecond response time for dynamic motion profiling.

- Multi-Axis Synchronization:

- Supports independent control of multiple axes, enabling coordinated motion in robotics and CNC systems.

- Flexible Feedback Options:

- Compatible with incremental/absolute encoders and Hall-effect sensors for versatile feedback integration.

- Compact Design:

- Space-saving form factor with integrated power supply and controller circuits.

- Diagnostics & Maintenance:

- Built-in self-test routines and fault logging for quick troubleshooting.

- LED indicators for real-time status monitoring (power, communication, alarms).

- Energy Efficiency:

- Active power factor correction (PFC) reduces harmonic distortion.

- Regenerative braking options to recover energy during deceleration.

Applications

- Robotics: Precision control of robotic joints in pick-and-place, welding, and assembly systems.

- CNC Machinery: High-speed spindle and feed axis control for milling, lathes, and grinding machines.

- Medical Devices: Accurate motion control in surgical robots and imaging systems.

- Semiconductor Manufacturing: Nanometer-level positioning for wafer handling and inspection.

- Packaging: Synchronized motion for labeling, filling, and sealing equipment.

- Electronics Assembly: Fine-pitch component placement and soldering automation.

Additional Capabilities

- Software Integration: Compatible with Kollmorgen’s WorkBench software for configuration, tuning, and diagnostics.

- Scalability: Supports daisy-chaining multiple drives for synchronized multi-axis systems.

- Global Compliance: Meets international standards (UL, CE, IEC 61800-5-2) for global deployment.

-500x500.jpg)

Reviews

There are no reviews yet.