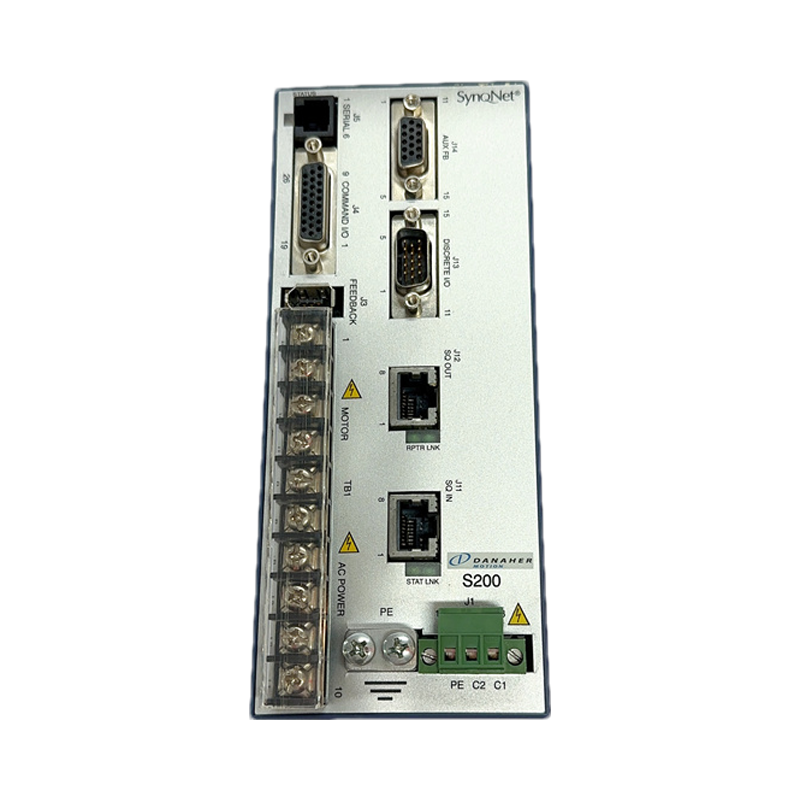

Product Short Description

Technical Specifications

- Input Voltage: 120 VAC or 240 VAC (single – phase / three – phase), with a wide – range voltage fluctuation tolerance of ±15%.

- Continuous Current Rating: 12 A.

- Peak Current Rating: 18 A (for 3 seconds).

- Speed Loop Bandwidth: Up to 800 Hz.

- Current Loop Bandwidth: 5 kHz.

- Feedback Resolution: 24 – bit.

Description

- Communication Interface: Pre – installed SynqNet (RJ45), supporting protocols such as Modbus, CAN bus, and EnDat.

- Control Modes: Position, speed, and torque modes.

- Operating Temperature: – 40°C to + 70°C (operating), – 40°C to + 85°C (storage).

- Protection Level: IP20 (needs to be installed in the control cabinet), with an optional IP67 protection shell.

Function Characteristics

- High – performance Motion Control

- Precise Response: With an 800 Hz speed loop bandwidth and a 5 kHz current loop bandwidth, it can achieve a positioning accuracy of ±1μm in semiconductor wafer transfer equipment, meeting nanometer – level processing requirements.

- Multi – mode Control: Supports flexible switching between position, speed, and torque modes. For example, in medical CT scanners, torque control is used to achieve the flexible movement of the robotic arm to avoid damaging patients.

- Intelligent Integration and Simplified Debugging

- Plug – and – Play: SFD technology automatically recognizes motor parameters without manual configuration. In electronic assembly lines, the single – axis debugging time is reduced from 2 hours to 15 minutes.

- Multi – protocol Compatibility: The SynqNet interface supports high – speed synchronous motion control. In packaging machinery, it can coordinate 20 servo motors to achieve microsecond – level synchronization of processes such as labeling and filling.

- Industrial – grade Reliability Design

- Wide Temperature Adaptation: With an operating range of – 40°C to + 70°C, it can operate continuously for 5 years without failure in the extreme environment of oil drilling platforms.

- Multiple Protections: It has over – current, over – voltage, and over – heat protection functions, combined with opto – isolated input / output, ensuring stable operation in strong electromagnetic interference environments such as metallurgical electric furnaces.

- Compact Design and Flexible Expansion

- Space – saving: With a compact size of 50mm × 50mm, it can be directly installed at the robot joint, reducing wiring complexity. For example, in surgical robots, the integrated design of the drive and motor saves 30% of the control cabinet space.

- Modular Expansion: Supports S200 series expansion modules, such as analog input / output cards, which can easily adapt to the needs of different industries.

Application Scenarios

- Industrial Automation: Such as robots, packaging machinery, and printing machinery.

- Semiconductor Manufacturing: Used for the precise control of wafer transfer platforms and semiconductor equipment.

- Medical Equipment: For the control of precision instruments, such as surgical robots and medical CT scanners.

- Textile Machinery: Such as the automation control of looms and knitting machines.

Be the first to review “KOLLMORGEN S21260-SRS” Cancel reply

Reviews

There are no reviews yet.