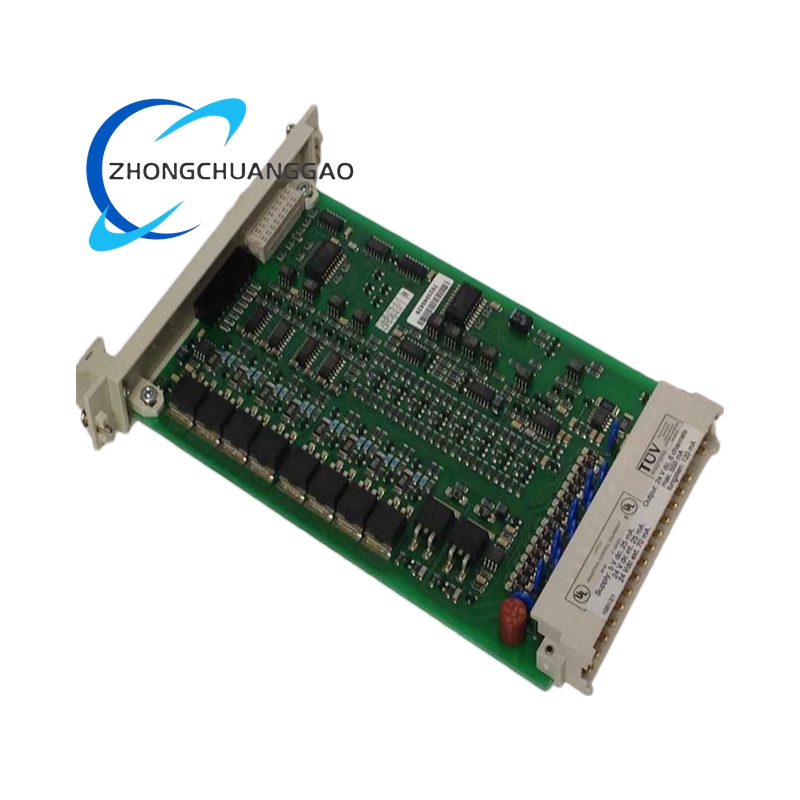

Product Short Description

- Technical Specifications

- Electrical Parameters: It adopts 24VDC nominal input voltage. The minimum on – state current is 2mA, the maximum off – state voltage is 5V, and the maximum off – state current is 1.5mA. The maximum power consumption is 6.1W. The channel – to – channel and user – to – system isolation voltages are both tested at 1500VDC for 1 second. It is compatible with IEC type 1 + input standards.

- Interface and Connection Parameters: It uses a TC – TBN H 36 – position terminal block for wiring. It is equipped with detachable two – level terminals, which can simplify the field wiring operation. The 32 input points are divided into two groups with 16 points per common terminal, realizing reasonable grouping management of input signals.

- Physical Parameters: Its dimensions are 18.4cm × 12cm × 4.7cm, and its weight is 0.28kg, while the shipping weight reaches 2kg. The compact size allows it to be installed in space – limited control cabinet environments without occupying too much space.

- Environmental Parameters: It can work stably in the ambient temperature range of -40°C to 70°C, and the storage temperature range is -40°C to 85°C. It can operate normally in an environment with 5% – 95% relative humidity without condensation, and the protection level is IP20.

Description

- Functional Features

- High – efficiency Multi – point Signal Collection: With 32 input points, it can simultaneously collect digital signals from multiple on – site devices such as limit switches and pushbuttons. The grouping design of 16 points per common terminal makes signal management more orderly, which improves the efficiency of signal collection in industrial automation systems and reduces the number of modules required for system configuration.

- Strong Signal Isolation and Anti – interference: The 1500VDC high isolation voltage between channels and between users and the system can effectively isolate interference signals between different circuits. This design ensures the integrity and accuracy of input signals, avoids signal distortion caused by industrial on – site electromagnetic interference, and ensures the reliable operation of the control system.

- Easy Installation and Maintenance: It adopts detachable terminal blocks for field wiring, which allows maintenance personnel to quickly disconnect and connect wires during installation and maintenance. Its compact structure and vertical mounting design are conducive to heat dissipation in the control cabinet and facilitate wiring from the top or bottom. It also eliminates the need for separate chassis for electronic components, reducing installation complexity.

- Wide System Compatibility: It can be seamlessly integrated with Honeywell’s TDC 2000, TDC 3000 and Plantscape systems. It can also be matched with mainstream PLC systems of many brands, breaking the limitations of single system application. This wide compatibility enables it to be flexibly applied to different industrial control systems and reduces the cost of system transformation and upgrading.

- Application Scenarios

- Petrochemical and Refining Industry: It is used in petrochemical plants and refineries to collect signals from sensors and switches on pipelines and reaction kettles. It monitors the opening and closing status of valves and the operating status of pumps in real time. The stable signal collection ensures the safe operation of the production process and provides data support for the centralized control of the whole production line.

- Power Generation Industry: In thermal power plants and other power generation facilities, it collects digital signals from various auxiliary equipment such as conveyor belts, coal feeders and induced draft fans. It helps the central control system grasp the operating status of each equipment in real time, realize timely adjustment and fault early warning, and ensure the continuous and stable operation of power generation equipment.

- General Manufacturing Production Lines: In manufacturing fields such as textile, printing and rubber and plastic processing, it monitors the status of sensors and switches on production machines. It feeds back the operating information of equipment such as stamping machines and assembly lines to the control system, which helps to realize the automation control of the production line and improve production efficiency and product quality stability.

- Building Automation Systems: It is applied to building automation projects such as large shopping malls and office buildings. It collects signals from sensors of air conditioning systems, lighting systems and access control systems. It realizes centralized monitoring and management of building equipment, optimizes the operation of building energy consumption systems, and creates a comfortable and energy – saving building environment.

Be the first to review “Honeywell TC-IDD321 32-Point 24VDC Digital Input Module” Cancel reply

-500x500.jpg)

Reviews

There are no reviews yet.