Product Short Description

- Technical Specifications

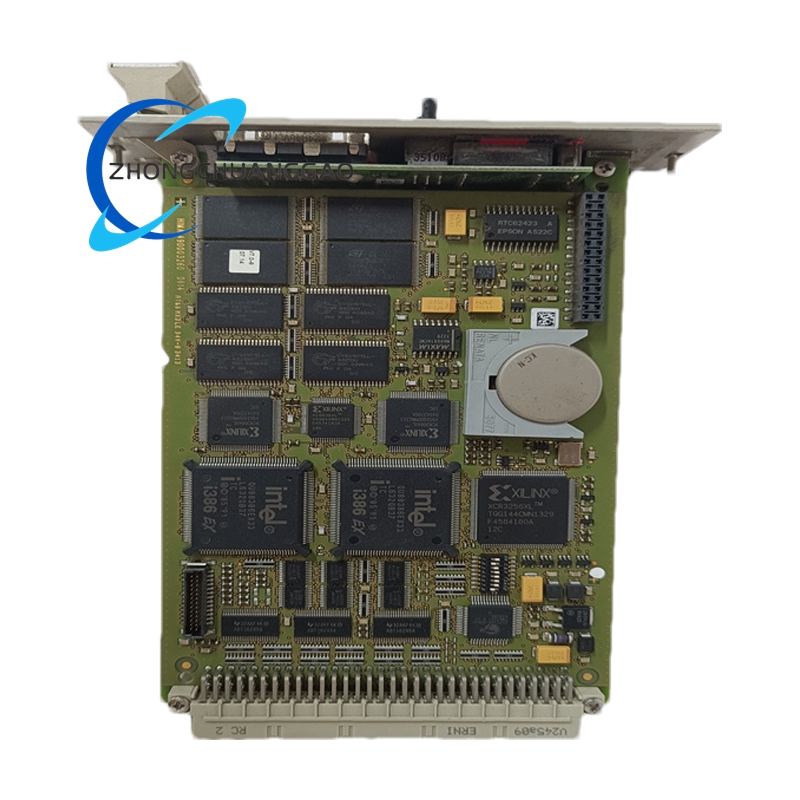

- Processor and Memory: It adopts dual Intel 386EX 32 – bit microprocessors with a synchronized processing frequency of 25 MHz. It is configured with 1MB of total memory, including 512KB flash – EPROM for user programs, 256KB SRAM for data storage with battery backup, and 1MB flash – EPROM for the operating system per processor. The flash – EPROM can withstand no less than 100,000 write cycles.

- Power Supply Parameters: It relies on the F7130A 24V DC/5V DC clock – controlled power module to obtain 5V DC power, with a maximum current of 2000mA and a maximum power consumption of 10W under full load. It uses a CR2477N lithium battery for backup, which can maintain the operation of critical data and the hardware clock during power outages, lasting 1000 days at 25°C and 200 days at 60°C.

- Communication Interfaces: It is equipped with two electrically isolated RS485 interfaces with 1500V RMS isolation on the communication lines. The baud rate can be programmed between 9.6 kbps and 115.2 kbps, and it also supports hardware switch settings of 9600 bps and 57600 bps, with software settings taking priority. It is compatible with the backplane bus system for connecting I/O modules and communication modules.

- Physical and Environmental Indicators: It occupies 8 TE space and consists of two European standard printed circuit boards. The operating temperature range is 0°C to 60°C, the storage temperature range is -40°C to 85°C, and it can work normally in an environment with 5% – 95% non – condensing humidity. It can resist 2g vibration during operation and 10g vibration when not in operation.

- Diagnostic Display: It is equipped with a four – digit alphanumeric display, two LED indicators for CPU and I/O status, two toggle switches for querying detailed error information, and an ACK reset button to eliminate error prompts.

Description

- Functional Features

- Dual – Processor Redundant Protection: The two synchronized microprocessors work in coordination. One processes real data and programs, while the other processes reversed data and programs. A testable hardware comparator monitors external access in real time. When a fault is detected, it immediately triggers the watchdog, switches the system to a safe state, and reports the fault status.

- Reliable Power Supply and Data Backup: The sub – rack is configured with two parallel power modules for mutual backup. The system monitors the 5V DC output voltage in real time and sends fault messages promptly when a power module malfunctions. The backup battery ensures that the SRAM data is not lost during power outages, and the battery needs to be replaced within 6 years or 3 months after the low – battery prompt appears.

- Strong Interface Protection and Stability: All communication ports are equipped with surge and ESD protection functions, and the communication lines have 1500V RMS isolation. It also has automatic current – limiting short – circuit protection, which can effectively resist interference from external electrical signals and prevent module damage caused by circuit faults.

- Convenient Fault Diagnosis: Through the four – digit alphanumeric display and LED indicators, it can intuitively display the system operating status. The toggle switches can be used to retrieve detailed error information, and the ACK button can reset error prompts. The rich error code library helps maintenance personnel quickly locate and solve problems.

- Flexible Station Number Setting: For the serial interface, the bus station number can be set from 1 to 31. In the Ethernet network, with additional switch settings, the bus station number can be expanded to 1 – 99, and the maximum number of communication partners in a single network is limited to 64.

- Application Scenarios

- Oil and Gas Industry: It is applied to the safety control systems of offshore oil platforms and onshore gas processing plants. It controls the operation of pipeline pressure monitoring equipment and gas leakage detection devices. It can quickly process abnormal data and trigger emergency shutdown procedures, avoiding large – scale leakage and explosion accidents caused by equipment failure or pipeline damage.

- Chemical Industry: It is integrated into the safety control systems of chemical reaction workshops. It processes parameters such as temperature, pressure, and reagent proportion in the chemical reaction process in real time. When parameters exceed the safe range, it can immediately issue control instructions to adjust the equipment or stop the reaction, preventing dangerous accidents such as out – of – control reactions.

- Power Industry: It is used in the control systems of thermal power plants and nuclear power plants. It manages the operating data of generator sets, transformers, and power transmission equipment. It monitors parameters such as current, voltage, and temperature in real time. It can quickly activate protective measures when abnormalities occur, avoiding equipment burnout and large – area power outages.

- Manufacturing Industry: It is deployed in automated production lines, especially in automobile manufacturing and electronic component production. It controls the operation of assembly equipment, quality inspection modules, and transportation systems. It ensures the accuracy and safety of each production process, reduces production errors, and improves the qualification rate of products while preventing equipment collision and personnel safety accidents.

- Traffic Tunnel Safety Systems: It is used to control the environmental monitoring and emergency equipment in traffic tunnels. It processes data from gas concentration sensors, temperature sensors, and smoke detectors. It can trigger ventilation equipment and fire – fighting systems in time when potential safety hazards are detected, and coordinate traffic signal changes to ensure the safe passage of vehicles.

Be the first to review “Hima F8652X 984865265 Safety-Related Central CPU Module” Cancel reply

Reviews

There are no reviews yet.