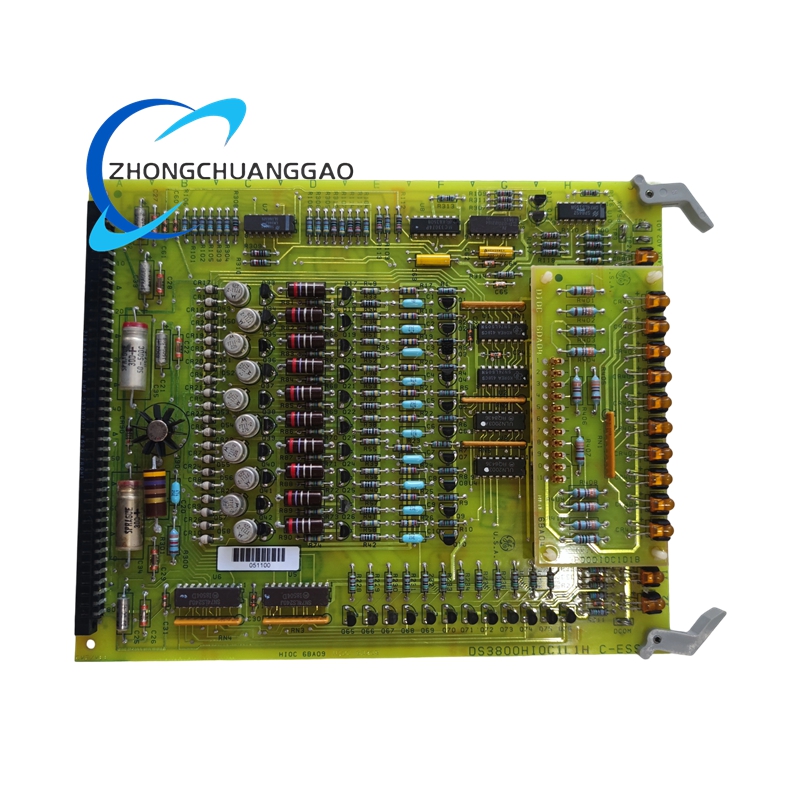

Product Short Description

Technical Specifications

- Electrical Parameters

- It has a rated voltage of 120V AC and an input voltage range of 110V – 240V, which enables it to adapt to different power supply environments in various industrial sites.

- It has an output voltage of 32V and an output current range of 0 – 20mA, which can meet the signal transmission needs of subsequent connected control components.

- It operates at a frequency of 47 – 63Hz and a speed of 150MHz, and its power consumption is only 2.6W, which achieves efficient voltage monitoring while maintaining low energy consumption.

- Communication and Hardware Parameters

- It is equipped with an RS485 communication interface, which supports stable data interaction between the board and other control modules in the industrial control system and ensures the timely transmission of voltage monitoring data.

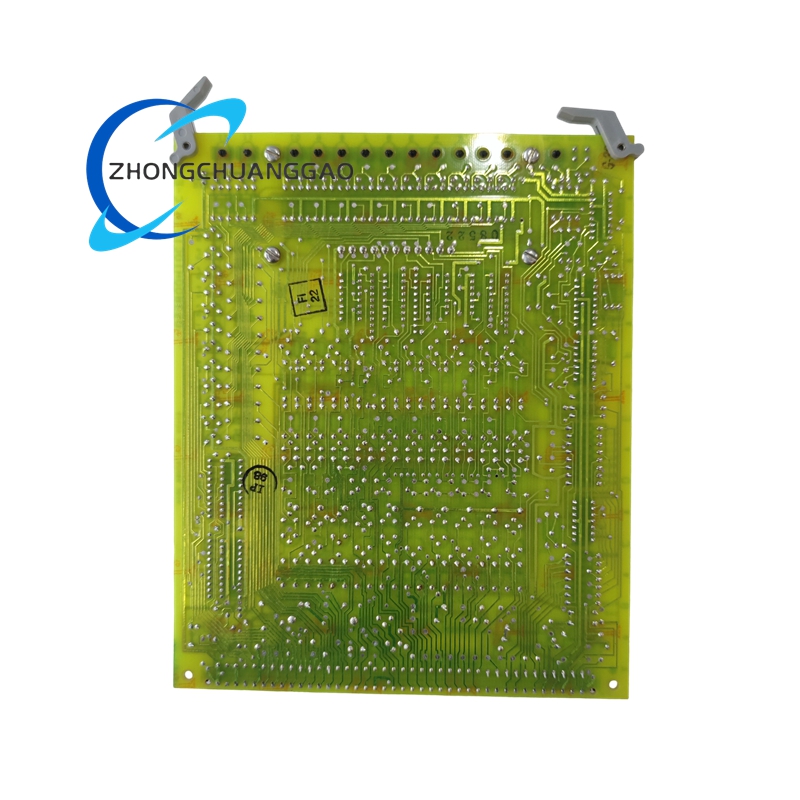

- It adopts a compact structural design with dimensions of 120mm x 80mm x 40mm, which is convenient for installation in limited space inside industrial control cabinets.

Description

- Physical and Environmental Parameters

- It weighs 0.13kg, which is lightweight and does not add excessive load to the system rack or installation platform.

- It can work stably in a temperature range of -40°C to 85°C, which can withstand extreme temperature conditions in both indoor industrial workshops and outdoor equipment sites.

- It holds CE certification, which indicates that it meets strict European industrial product safety and quality standards.

Function Features

- High – Precision Voltage Monitoring

The board is designed with high – precision voltage detection circuits that can accurately capture tiny changes in the voltage of monitored equipment. It provides reliable and real – time voltage data for the upper – level control system. This high precision ensures that the control system can promptly detect abnormal voltage phenomena such as over – voltage and under – voltage, which lays a foundation for timely protective measures.

- Strong Anti – Interference and Operational Stability

The adoption of industrial – grade electronic components enhances the board’s ability to resist electromagnetic interference. In industrial environments with numerous high – power equipment and complex electromagnetic fields, it can avoid signal distortion caused by interference. It maintains stable operation and ensures the continuity and accuracy of voltage monitoring data without being affected by external environmental factors.

- Integrated Alarm and Data Recording Functions

In addition to basic monitoring, the board integrates alarm and data recording functions. When the monitored voltage exceeds the preset safe range, it immediately triggers an alarm signal to remind operators to handle the problem. At the same time, it automatically records voltage data and abnormal events. These recorded data can be used for subsequent system maintenance analysis and fault tracing.

- Easy Integration with Various Industrial Systems

The board follows universal industrial interface standards and has a compact size. It can be seamlessly integrated into industrial automation systems, power control systems, robot control systems and other different types of industrial control systems. It does not require large – scale transformation of the original system structure, which reduces the difficulty and cost of system upgrading and transformation.

Application Scenarios

- Voltage Monitoring in Industrial Automation Production Lines

In automobile manufacturing, electronic component assembly and other industrial automation production lines, this board monitors the voltage of key equipment such as robotic arms, conveyor belts and automated processing machines. It triggers alarms in case of voltage abnormalities and records related data. This prevents production interruptions or product quality defects caused by voltage fluctuations and ensures the continuous and stable operation of the production line.

- Stability Guarantee for Power System Equipment

In thermal power plants, hydropower stations and other power systems, the board is installed in the control systems of generators, transformers and power distribution cabinets. It monitors the voltage of these core power equipment in real time. It helps the power dispatch system adjust parameters in a timely manner when voltage deviations occur, which avoids equipment damage caused by unstable voltage and ensures the safe and reliable supply of electric energy.

- Voltage Protection for Robot Systems

Modern industrial robots are highly dependent on stable voltage supply. The DS3800HIOC is integrated into robot control systems to monitor the voltage of the robot’s power supply module and drive module. It ensures that each movement joint and execution component of the robot receives stable voltage support, which prevents robot malfunctions or movement inaccuracies caused by voltage problems and improves the operation accuracy and reliability of robots.

- Voltage Supervision in Manufacturing Equipment

In refineries and chemical plants, the board monitors the voltage of mixing machines, reactors and other production equipment. The harsh production environments in these fields have high requirements for equipment stability. The board’s anti – interference and wide temperature adaptability enable it to stably monitor voltage, which avoids safety accidents such as equipment leakage or material reaction failures caused by voltage abnormalities.

- Voltage Monitoring in Building Automation Systems

In large commercial buildings and industrial workshops with building automation systems, the board is used to monitor the voltage of central air – conditioning systems, lighting systems and elevator operation systems. It ensures that these public facilities operate within a stable voltage range, which reduces equipment maintenance costs and improves the comfort and safety of building use.

Reviews

There are no reviews yet.