Product Short Description

Technical Specifications

- Electrical Parameters

- It operates on a 28VDC power supply that matches the power supply standard of the Mark V series control system and ensures stable power support for analog signal processing and component operation.

- It supports analog input signals from multiple types of sensors such as thermocouples and thermistors, and can process and transmit these signals to achieve high-precision measurement and control of parameters like temperature.

- It integrates over-temperature protection and short-circuit protection circuits that cut off relevant circuits promptly when electrical anomalies occur to avoid board damage.

- Hardware and Interface Parameters

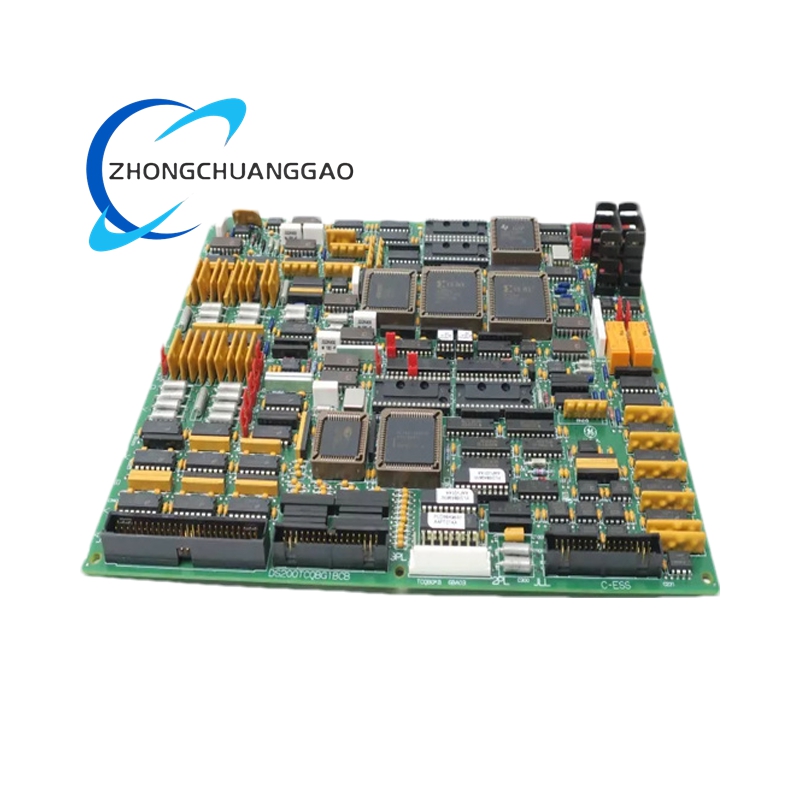

- It is equipped with a 50-pin connector labeled JKK and 34-pin connectors. These connectors realize stable connection with other modules in the Mark V system and transmit analog signals and control instructions efficiently.

- It is configured with 15 jumpers that allow technicians to adjust hardware settings to customize the board for different application requirements and ensure compatibility with various sensors and matching modules.

- It is built with a programmable logic device and a dedicated slot for an EPROM module, which together execute and store the logic programs required for analog signal processing.

Description

- Physical and Environmental Parameters

- It has a weight of 0.35 kilograms and dimensions of 12cm×21cm×2.5cm, with a compact structure that fits perfectly into the standard slot of the Mark V system cabinet.

- It adopts a standard ordinary PCB protective coating and can maintain stable performance in an operating temperature range of -30°C to 65°C, adapting to large temperature fluctuations in various industrial environments.

Function Features

- Expanded Analog Signal Processing Capacity

The core function of this board is to expand the analog I/O capability of the Mark V turbine control system. It can connect to multiple industrial sensors simultaneously and receive a large number of analog signals related to turbine operation, such as temperature, pressure and flow. By processing these signals uniformly, it enables the Mark V system to monitor more operational parameters of turbines, which lays the foundation for precise control of turbine operation.

- Customizable Configuration via Jumpers

The 15 jumpers on the board provide flexible hardware configuration options. Technicians can adjust the jumpers according to the type of connected sensors, signal transmission standards and system control requirements. This customizable design allows the board to adapt to different turbine models and industrial application scenarios without the need for replacing the entire board or modifying the core system program.

- Intuitive Operational Status Monitoring

The board is equipped with a side-visible OK LED indicator. The indicator lights up when the board is powered on and operating normally. It stays off or displays abnormal status when malfunctions such as circuit faults or poor signal connections occur. This visual prompt allows maintenance personnel to quickly confirm the board’s working condition and shorten the time required for fault location without disassembling the entire control cabinet.

- Intuitive Operational Status Monitoring

- Flexible Compatibility with EPROM Matching

It relies on an EPROM module to store firmware and program instructions for the programmable logic device. The design that separates the board and the EPROM module allows users to reuse the EPROM module from the old board. This not only reduces replacement costs but also ensures the consistency of control logic before and after the board replacement, avoiding system operation exceptions caused by program inconsistencies.

Application Scenarios

- Thermal Power Plant Steam Turbine Monitoring

It is widely used in the Mark V control systems of steam turbines in thermal power plants. It connects to temperature sensors on turbine casings and pressure sensors in steam pipelines. It processes the collected analog signals and transmits them to the system’s main control unit. The unit then adjusts the steam intake volume and turbine speed based on the signals, ensuring stable power output and preventing equipment damage due to excessive temperature or pressure.

- Oil and Gas Refinery Turbine Control

Oil and gas refineries use gas turbines to drive large compressors and transfer pumps. This board integrates into the supporting Mark V control systems. It receives analog signals from flow sensors in oil and gas pipelines and pressure sensors in compression chambers. It processes these signals to coordinate the operation of turbines and compressors, ensuring the stability of oil and gas compression and transportation processes and maintaining the continuity of the refining production line.

- Wind Power Farm Turbine Parameter Regulation

In wind power farms using Mark V control systems, this board connects to wind speed sensors, blade angle sensors and temperature sensors inside wind turbines. It processes the analog signals of these sensors and feeds data such as real-time wind speed and component temperature back to the central control system. The system adjusts the blade angle and turbine operating status accordingly to maximize wind energy utilization while protecting the turbine from damage caused by extreme wind speeds or overheating.

- Metallurgical Plant Thermal Equipment Temperature Control

Many metallurgical plants use turbines to power high-temperature smelting equipment and rely on the Mark V system for control. This board functions as a temperature measurement and control module in the system. It collects analog signals from thermocouples in blast furnaces and smelting furnaces, processes and converts the signals into control commands. These commands regulate the heating intensity of the equipment, ensuring that the smelting temperature meets process requirements and improving the quality of metal products.

- Legacy Mark V System Maintenance in Heavy Industry

For heavy industrial fields such as chemical engineering and mining that still operate legacy Mark V turbine control systems, this board serves as a critical maintenance spare part. When the original analog I/O board malfunctions and causes signal transmission interruptions or parameter measurement inaccuracies, replacing it with the DS200TCQBG1BCB can quickly restore the system’s analog signal processing capability, minimize production downtime and reduce economic losses caused by equipment outages.

Reviews

There are no reviews yet.