Product Short Description

Technical Specifications

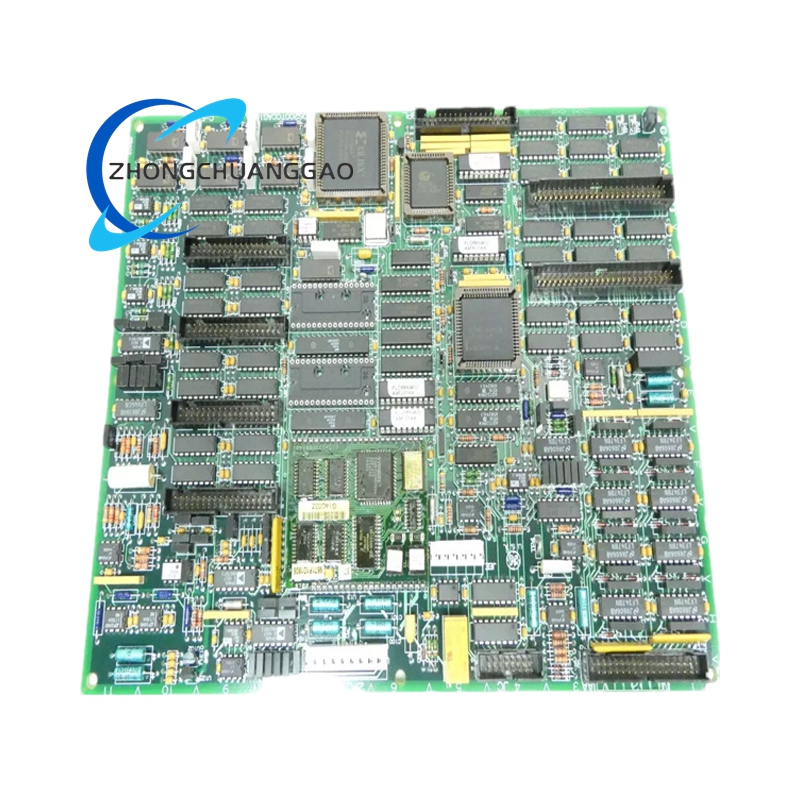

- Processor and Storage Parameters

- It integrates an 80196 microprocessor that efficiently manages analog signal processing tasks such as signal filtering, amplification and conversion, ensuring rapid and accurate processing of various industrial control signals.

- It is equipped with multiple programmable read – only memory modules that store instructions and firmware required for the operation of the microprocessor and programmable logic devices. The stored content can be erased and updated to adapt to different system operation requirements.

- It is fitted with a single LED that provides visual indication of the board’s operating status, enabling technicians to quickly judge basic working conditions.

- Electrical and Communication Parameters

- It handles a variety of signal types, covering LVDT position inputs, servo valve drive outputs, thermocouple temperature inputs, 4 – 20mA current signals, ±10V DC voltage inputs and vibration signals, which meets the diverse signal processing needs of turbine systems.

- It is configured with two 50 – pin connectors labeled JCC and JDD, which realize connections with external sensors, actuators and other internal boards of the system. It communicates with the STCA board via the 3PL connector and exchanges generator and line signals with the TCQC board through the JE connector.

- Hardware jumpers are set for functional configuration. Jumpers are used to select the milliamp output circuit and configure the milliamp output current range between 20mA and 200mA, and one specific jumper is used for card testing via the RS232 port.

Description

- Physical and Environmental Parameters

- It adopts a normal PCB coating with clear functional and artwork revisions, and the LED can be seen from the side of the board for easy status checking.

- It has a weight of 2.5 kilograms and dimensions of 20cm×25cm×30cm, which is consistent with the standard module size of the Mark V system, enabling direct installation into the corresponding slots of the system cabinet.

- It adopts a rugged design that adapts to the harsh operating environments of industrial sites, and can maintain stable performance in the temperature and humidity ranges required for turbine control system operation.

Function Features

- Comprehensive Analog Signal Processing Capability

The board can complete multiple processes such as collection, filtering, amplification, isolation and conversion of analog signals. It scales and conditions 4 – 20mA input signals like compressor stall detection signals and fuel flow pressure signals. It also processes special signals such as thermocouple inputs with cold – end compensation, ensuring that all signals meet the requirements of the Mark V system for subsequent processing and analysis.

- Flexible Configuration and Upgradability

The multiple PROM modules on the board support flexible programming and customization. Technicians can update the firmware and instructions stored in the PROM modules according to changes in system control requirements, without replacing the entire board. This flexibility greatly improves the adaptability of the board to different turbine operation scenarios and control strategies.

- Flexible Configuration and Upgradability

- Clear Fault Diagnosis and Status Monitoring

The LED status indicator on the board provides intuitive visual feedback. It displays different states according to the board’s power supply, signal processing and communication conditions. When a fault occurs such as signal loss or communication interruption, the LED will show a corresponding alarm state, helping technicians quickly locate problems during maintenance and shorten troubleshooting time.

- Stable Inter – board Collaboration and Signal Transmission

It realizes standardized connections and data transmission with STCA, TCQC and other boards through dedicated connectors such as 3PL and JE. The defined connector functions ensure that signals such as generator line signals, trip signals and servo valve outputs are accurately transmitted between different modules of the system, forming a complete signal transmission chain and guaranteeing the coordinated operation of the entire turbine control system.

Application Scenarios

- Gas and Steam Turbine Control in Power Plants

It is widely used in the Mark V control systems of gas and steam turbines in thermal power plants and industrial power stations. It processes real – time signals such as turbine bearing vibration, fuel flow pressure and exhaust temperature. It converts these analog signals into digital signals that the system can recognize and transmits them to the central controller. It also sends control signals to servo valves and other actuators to adjust the turbine’s operating parameters, ensuring stable power output and safe operation of the turbine.

- Wind Turbine Control Systems

In wind power generation projects, this board is integrated into the Mark V – based wind turbine control systems. It processes analog signals from wind speed sensors, blade angle sensors and generator temperature sensors. It helps the system adjust the blade angle and generator operating state according to changes in wind conditions, maximizing wind energy utilization while protecting the wind turbine from damage caused by extreme wind speeds.

- Petrochemical Turbine – Driven Equipment

In petrochemical refineries and natural gas processing plants, it is applied to the control systems of turbines that drive compressors and transfer pumps. It processes pressure and flow signals in oil and gas pipelines and adjusts the turbine’s output power according to the process requirements. It ensures the stability of oil and gas compression, transportation and processing processes, and prevents production accidents caused by unstable equipment operation due to signal processing failures.

- Hydroelectric Power Plant Supporting Control

In hydroelectric power plants, this board is used in the Mark V control systems of water turbines. It processes signals such as water flow rate, water pressure and turbine speed. It coordinates the operation of the water turbine and the generator by transmitting and conditioning these signals, ensuring the efficient conversion of water energy into electrical energy and realizing the stable operation of the hydroelectric power generation unit.

- Maintenance of Legacy Mark V Control Systems

It serves as a key spare part for industries such as energy, manufacturing and heavy industry that still rely on the Mark V series control systems. When the original analog I/O board malfunctions and leads to distorted signal processing or interrupted system communication, replacing it with the DS200TCCAG1BAA can quickly restore the normal operation of the control system. It avoids the huge cost of replacing the entire control system and effectively extends the service life of the legacy equipment.

Reviews

There are no reviews yet.