Product Short Description

Technical Specifications

-

- Processor and Storage Parameters

- It integrates a LAN Control Processor that specializes in processing Ethernet protocol operations and data forwarding tasks to ensure smooth data interaction between the host drive and the upper-level system.

- It is configured with two removable EPROM cartridges to achieve program redundancy, which prevents system failure caused by a single storage component malfunction.

- It is equipped with a dual-port RAM that enables high-speed data communication between the LAN Control Processor and the host drive’s drive control processor without transmission delays.

- Electrical and Communication Parameters

- The standard power supply is 24V DC, and some models support 120 – 240V AC input. The internal power module has overvoltage and overcurrent protection functions to avoid damage caused by power fluctuations.

- It is equipped with a 10/100 Mbps Ethernet interface with an RJ – 45 connector for stable connection to the enterprise local area network.

- It supports matching with the communication protocols of Mark V and Mark VIe systems to realize seamless connection with the upper – level control system.

- Processor and Storage Parameters

Description

- Physical and Environmental Parameters

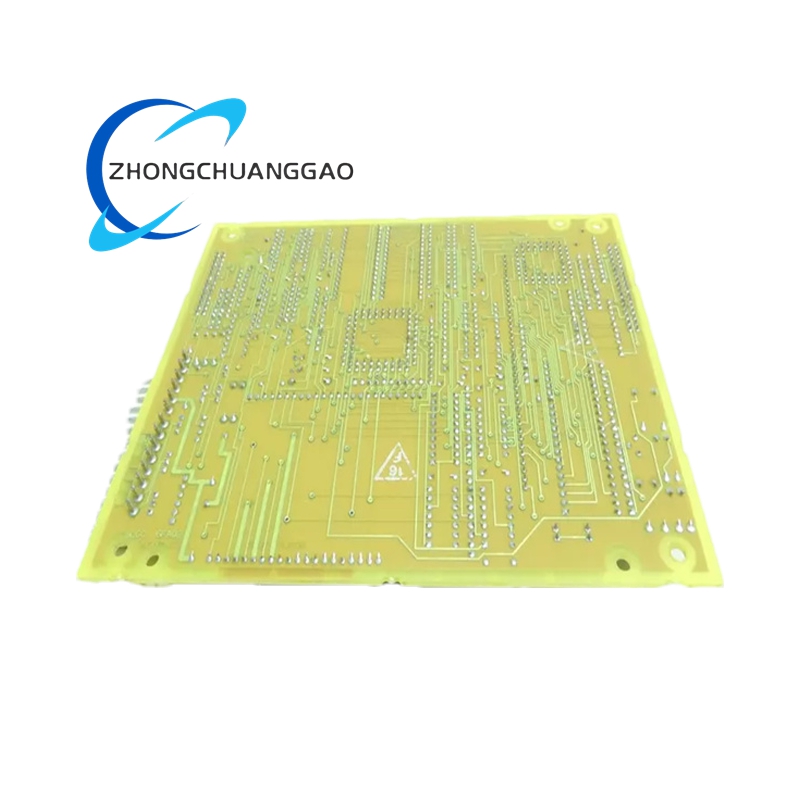

- The PCB adopts a normal coating, with functional revisions A and C, and an artwork revision C, which enhances the anti – interference performance of the board.

- It has an operating temperature range of -20°C to +60°C and can maintain stable performance in harsh industrial temperature environments.

- It weighs about 2.5 kilograms, with dimensions of 20cm×25cm×30cm, conforming to the standard module size of the Mark V system cabinet for direct installation.

Function Features

- Dual Storage Redundancy for High Reliability

The two EPROM cartridges on the card form a program redundancy structure. When one cartridge fails to read or write data normally, the system can automatically switch to the other intact cartridge to run the program. This design avoids system downtime caused by single – point storage failures and greatly improves the continuous operation capability of the control system.

- Dual Circuit Options for Strong Adaptability

It provides both isolated and non – isolated circuit versions for users to choose from according to on – site safety requirements. The isolated version can effectively isolate external electrical interference and protect the internal components of the card and the connected equipment. The non – isolated version is suitable for stable internal environments with low interference, meeting the diverse needs of different application scenarios.

- Convenient On – site Diagnosis and Maintenance

It is equipped with a programming keyboard interface. Technicians can directly connect a programming keyboard to read system diagnostic information and quickly locate fault points such as communication interruptions or EPROM errors. During firmware upgrades, users only need to write the new firmware into the EPROM cartridge and insert it into the slot, and the system will automatically switch to the new version, simplifying the upgrade process.

- Plug – and – Play and Hot – Swap Support

The modular design allows the card to be directly installed into the corresponding slot of the Mark V system cabinet. It supports hot – swapping, enabling technicians to quickly replace faulty cards without shutting down the entire system, which shortens equipment maintenance time and reduces production losses caused by shutdowns.

- Strong Compatibility with Multiple Systems

It is fully compatible with various GE drives and exciters. It can not only work stably with the Mark V control system but also be seamlessly connected to the Mark VIe series controllers. This cross – series compatibility makes it applicable to the upgrading and maintenance of multiple generations of GE control systems.

Application Scenarios

- Turbine Control Systems in Power Plants

It is widely used in the Mark V control systems of gas turbines and steam turbines in thermal power plants and industrial power stations. It realizes data transmission between the turbine drive system and the upper – level monitoring platform, such as transmitting fuel flow, exhaust temperature and other signals to the control center, and receiving control instructions from the center to adjust the turbine operation state. It ensures the stable output of the turbine and the safe operation of the power generation system.

- Petrochemical Process Automation Equipment

In petrochemical refineries and natural gas processing plants, this card is integrated into the control systems of turbines driving compressors and transfer pumps. It transmits process signals such as pressure and flow during oil and gas processing through the local area network, and coordinates the operation of various equipment. It ensures the stability of the oil and gas transmission and processing links and avoids production interruptions caused by communication failures.

- Heavy Industry Production Lines

In papermaking and steel mills, it is applied to the control systems of various production – supporting motors and drives. In steelmaking blast furnace systems, it can transmit air supply pressure and temperature signals to adjust the operation of turbine – driven blowers. In papermaking production lines, it coordinates the speed of each section of the paper machine by transmitting data, ensuring the continuity and stability of the production process.

- Large – scale Pumping Stations and Compressor Drives

For large – scale water supply pumping stations and industrial compressor stations, the card is used to connect the drive control system of the pumping station and compressor to the central control room. It realizes remote monitoring and control of equipment operation parameters, adjusts the rotational speed of pumps and compressors according to actual demand, and improves energy utilization efficiency while ensuring stable water supply and gas supply.

- Legacy Mark V System Maintenance

It is an essential spare part for industrial enterprises that are still using the Mark V control system. When the original communication board fails and leads to blocked data transmission between the system and equipment, replacing it with the DS200SLCCG3ACC can quickly restore the communication function. It avoids the huge cost of replacing the entire control system and effectively extends the service life of the legacy equipment.

Reviews

There are no reviews yet.