Product Short Description

Technical Specifications

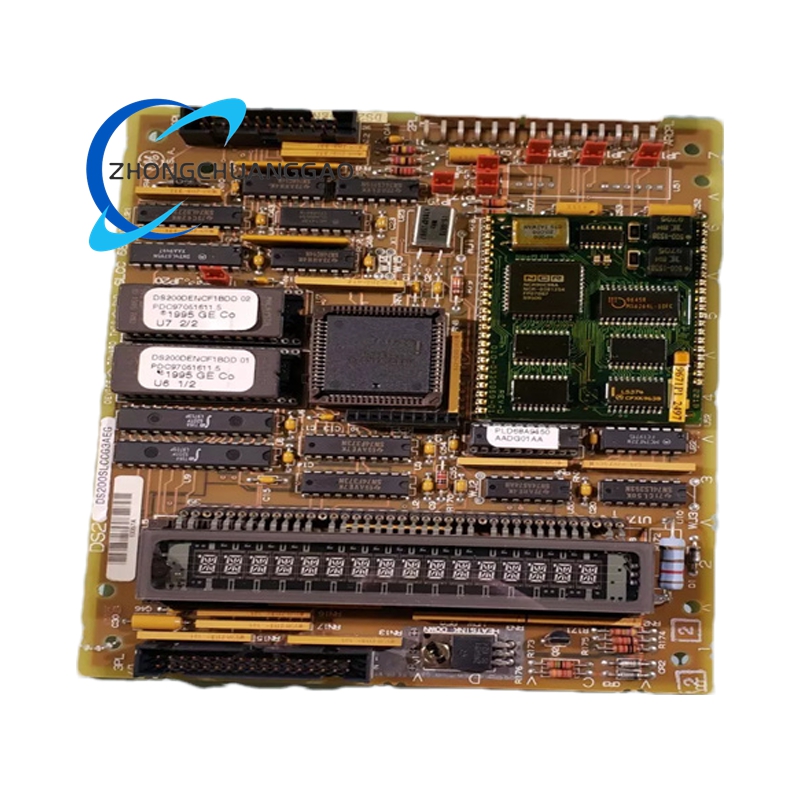

- Processor and Storage Parameters

- It is equipped with a LAN control processor that undertakes the core task of filtering and processing all incoming and outgoing signals of the card to ensure the accuracy and validity of signal transmission.

- It is configured with two detachable EPROM memory cartridges for program storage, allowing for easy program updates or replacements without modifying the entire card’s hardware.

- It features dual – port RAM that realizes high – speed data exchange between the LAN control processor and the host drive control card, ensuring no delays in key control data transmission.

- Circuit and Communication Parameters

- It provides both isolated and non – isolated communication circuits to meet the signal transmission needs of different industrial environments and equipment connection requirements.

- It supports multiple LAN protocols including TCP/IP, Ethernet, and Modbus, enabling seamless integration with various industrial control network architectures.

- It establishes a high – speed data link with the host system, which guarantees efficient data transmission and avoids bottlenecks in data communication during peak operation of the control system.

Description

- Physical and Manufacturing Parameters

- Its printed circuit board adopts a normal coating process, which enhances the board’s resistance to dust and mild corrosion, adapting to general industrial site environments.

- It has a functional revision of 1A and belongs to the DS200 product line of the Mark V series, with a standardized design that matches the slot specifications of the Mark V and EX2000 system cabinets.

- It supports connection with an attachable alphanumeric programmer keypad, which provides a convenient manual operation interface for on – site debugging and parameter configuration.

Function Features

- Dual – Circuit Design for Stable Communication

The integration of both isolated and non – isolated communication circuits on the card adapts to different industrial scenarios. Isolated circuits prevent interference from external voltage fluctuations or electromagnetic signals from affecting the card’s internal components and signal accuracy, while non – isolated circuits meet the needs of short – distance, low – interference, and high – efficiency signal transmission. This dual – circuit design ensures stable communication even in complex industrial electromagnetic environments.

- Multi – Protocol Support for Strong Compatibility

The card supports a variety of mainstream LAN communication protocols. This compatibility allows it to be seamlessly connected to different types of industrial control systems and equipment, not just limited to GE’s own Mark V and EX2000 systems. It can integrate into industrial networks using different protocols, reducing the need for additional adapter equipment and lowering the cost of system transformation and expansion for enterprises.

- Convenient Debugging and Diagnostic Functions

The matching alphanumeric programmer keypad enables users to directly access system settings and diagnostic functions on – site. Technicians can quickly adjust parameters, read fault codes, and perform functional tests through the keypad without relying on complex external debugging equipment. Additionally, the card supports multiple diagnostic and monitoring functions, which can real – time feed back its own operating status and communication links, facilitating timely troubleshooting.

- Reliable Data Transmission and Storage

The combination of the LAN control processor and dual – port RAM ensures high – speed and accurate data interaction with the host. The dual – port RAM allows the host drive control card and the LAN control processor to access data simultaneously without conflicts, improving data transmission efficiency. The detachable EPROM memory cartridges not only securely store programs but also allow for quick replacement when program upgrades or repairs are needed, ensuring the card’s long – term stable operation.

- Robustness for Harsh Industrial Environments

With its normal – coated circuit board and rugged structural design, the card can withstand harsh conditions such as dust, temperature changes, and minor vibrations common in industrial sites. It maintains stable performance in the temperature range suitable for industrial control equipment, which is applicable to the harsh operating environments of power plants, petrochemical workshops, and other places, reducing the frequency of card failures and replacement.

Application Scenarios

- Gas and Steam Turbine Control Systems

It is widely used in the Mark V control systems of gas and steam turbines in thermal power plants and industrial parks. It realizes data transmission between the turbine control unit and upper – level management systems. During turbine start – up, load adjustment, and shutdown, it transmits control commands and real – time operating parameters such as speed and temperature. It ensures that the control system can promptly adjust operating strategies, maintaining stable power output and safe operation of the turbines.

- EX2000 Drive System Matching

It is specifically adapted to GE’s EX2000 drive systems, which are widely used in large – scale mechanical equipment such as industrial compressors and fans. The card enables the EX2000 drive to communicate with the central control room through the LAN. It transmits drive status signals and receives adjustment instructions, ensuring that the drive can accurately adjust speed and torque according to production needs and improving the operational efficiency of the associated mechanical equipment.

- Petrochemical Process Automation

In petrochemical refineries and chemical plants, this card is integrated into the control systems of reactors, distillation towers, and pipeline transportation equipment. It is responsible for transmitting data between on – site control modules and the central control system. For example, it sends the temperature, pressure, and flow signals of chemical reaction processes to the central control room, and transmits the adjusted control commands back to the on – site execution components, ensuring the stability and safety of chemical production processes.

- Heavy Industry Production Lines

It plays a role in the automated production lines of industries such as metallurgy and papermaking. In metallurgical plants, it connects the control systems of blast furnaces and rolling mills to the factory’s central network, realizing the coordination of multiple equipment operations. In papermaking workshops, it communicates with the drive control systems of papermaking rollers and pulp conveyors, ensuring that each section of the production line operates in a synchronized manner and maintaining consistent product quality.

- Large – Scale Water Pump and Compressor Systems

It is applied to the control systems of large – scale water pumps in water supply plants and sewage treatment plants, as well as industrial compressors in manufacturing workshops. It transmits the operating data of water pumps and compressors, such as pressure and flow, to the central control platform. The platform then sends adjustment commands through the card to control the equipment’s operating power. It ensures stable water supply pressure and stable air supply for compressors, and improves the energy efficiency of the equipment.

- Legacy Industrial Control System Maintenance

For enterprises still using the obsolete Mark V series control systems, the card serves as a key maintenance spare part. When the original communication card in the system is damaged, replacing it with the DS200SLCCG3A can quickly restore the system’s communication function. It avoids the huge cost and operational interruption caused by replacing the entire control system, helping enterprises extend the service life of their existing equipment.

Reviews

There are no reviews yet.