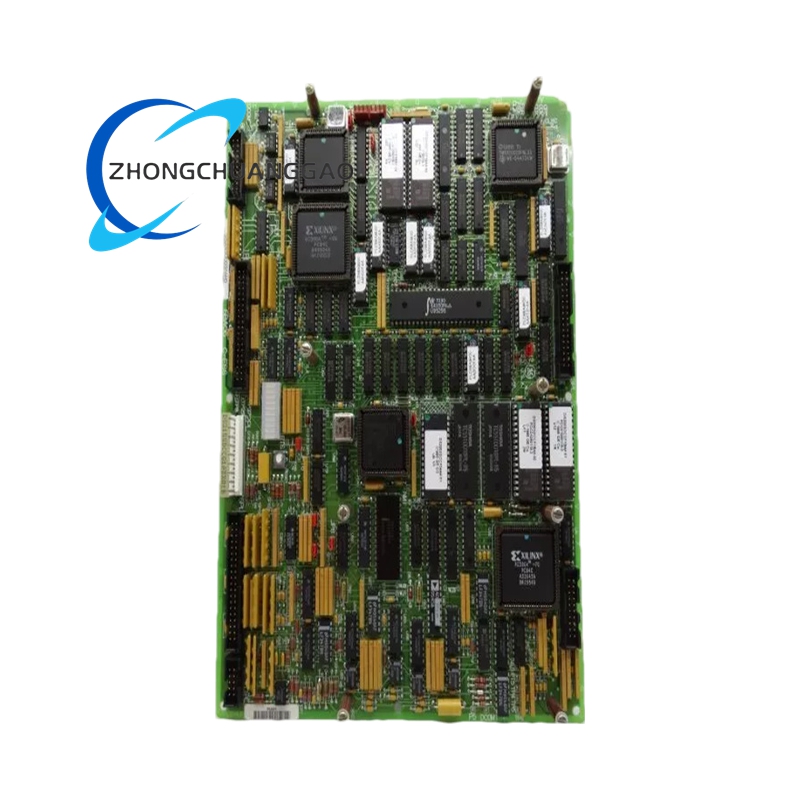

Product Short Description

Technical Specifications

- Processor and Memory Parameters

- It is equipped with three independent microprocessors, which separately undertake drive control, motor control, and math-intensive computing tasks to achieve refined division of labor in processing operations.

- It is configured with shared RAM that allows simultaneous access by multiple microprocessors, ensuring efficient data sharing and collaborative work between different processing units.

- Power and Interface Parameters

- It obtains power through the 2PL card interface, supporting +5VDC, +15VDC, and +24VDC input voltages supplied by the power supply/interface board to meet the power requirements of different functional modules.

- It supports installation of auxiliary boards including DS215SLCC or 531X306LCC LAN communication cards, 531X309SPC signal processor cards, and DS200SPCB multibridge signal processor cards for functional expansion.

- It is equipped with Ethernet and RS485 communication interfaces to realize stable data transmission with other system components.

Description

- Physical and Environmental Parameters

- The net weight of the card is 495 grams, with a compact structure that fits the standardized card rack of the Mark V system for easy installation and disassembly.

- Its printed circuit board adopts a normal coating process and can operate stably in the temperature range of -40°C to +70°C, adapting to the harsh environmental conditions of industrial sites.

Function Features

- Refined and Efficient Multi-Task Processing

The three microprocessors on the card perform their respective duties. One focuses on executing drive control commands such as start, stop, acceleration, and deceleration, while the other two are dedicated to motor control work, with one specifically responsible for complex mathematical operations. This division of labor reduces mutual interference between tasks and significantly improves the speed and accuracy of control command execution and data processing.

- Flexible Functional Expansion and Compatibility

The card supports the installation of multiple types of auxiliary boards such as LAN communication cards and signal processor cards. The optional LAN communication card is equipped with a serial connector, which can be connected to a laptop through a serial cable for configuration parameter modification and file uploading. It is highly compatible with GE’s AC2000, DC2000, and EX2000 drive systems and can be seamlessly integrated into the Mark V series control architecture without additional adaptive modifications.

- Comprehensive Signal Processing and System Coordination

It can comprehensively process various signals from drives and control systems, including speed, current, temperature, and torque signals. After filtering and analyzing these signals, it converts them into usable data and transmits them to other control modules through communication interfaces. This realizes the overall coordinated control of the system and ensures that each component of the turbine and drive system operates in a unified and synchronized manner.

- Proactive Fault Diagnosis and Safe Maintenance

The card is equipped with advanced self-diagnostic functions that can real-time monitor its own operating status and the signals of connected components. It quickly detects abnormal conditions such as signal anomalies and communication interruptions. When configuring or maintaining the card, users only need to follow standardized steps to connect the laptop and install configuration software to complete parameter adjustment and file updates. It also reminds users to turn off the drive before disconnecting the serial cable to avoid safety hazards caused by contact with high-energy currents.

Application Scenarios

- Gas and Steam Turbine Control Systems

It is widely used in the control systems of gas and steam turbines in thermal power plants and industrial parks. It controls the start and operation of turbines, processes key signals such as turbine speed and exhaust temperature, and adjusts operating parameters in real time. It ensures the stable output of turbine power and prevents equipment damage due to parameter deviations, laying a foundation for the safe and efficient operation of power generation equipment.

- Wind Turbine Power Generation Systems

In wind power generation projects, this control card is integrated into the drive control system of wind turbines. It copes with the instability of wind energy by precisely regulating the speed and torque of wind turbine generators. It processes wind speed and generator load signals in a timely manner, controls the start and stop of the generator and the adjustment of the fan angle, and maximizes the conversion efficiency of wind energy while ensuring the stable operation of the generator.

- Industrial Drive System Applications

It is applied to DC2000 and AC2000 drives in various industrial fields such as metallurgy and papermaking. It is used to control the drive equipment of key production machinery such as conveyor belts, mixers, and pulp machines. It realizes precise control of the speed and torque of the equipment, ensuring the stability of the production line. For example, in papermaking workshops, it can adjust the operation speed of papermaking rollers to ensure uniform thickness of paper products.

- Energy and Power Supply Support Systems

It plays a role in UPS power systems and electric vehicle charging stations. In UPS systems, it monitors and adjusts the power conversion process to ensure the continuous and stable output of electric energy and avoid power outages affecting the operation of key equipment. In electric vehicle charging stations, it controls the charging current and voltage, ensuring safe and efficient charging of electric vehicles while protecting the charging equipment from damage caused by current and voltage fluctuations.

- Industrial Water Treatment and Environmental Protection Equipment

In water supply and sewage treatment plants, this control card is used to control the drive systems of water pumps, blowers, and other equipment. It adjusts the operating power of the equipment according to the water level, water quality, and flow signals collected on site. It ensures the stability of water supply pressure and the efficiency of sewage treatment processes, and helps to improve the automation level and operational efficiency of environmental protection equipment.

Reviews

There are no reviews yet.