Product Short Description

Technical Specifications

- Electrical Parameters

- It supports 4 – 20mA input and output signals, and the mA output current range can be configured to 20mA or 200mA through hardware jumpers J5 and J6 to adapt to different signal transmission requirements of external equipment.

- It accepts +/-10V DC input signals, which are mainly used to receive vibration input signals transmitted from the JGR connector of the TBQB terminal board.

- It bears thermocouple input signals and cold – junction compensation signals, and the cold – junction compensation signals are carried by the JA of the TBQA board connector.

- It matches the power supply distributed by the TCPS board through the 2PL connector, which ensures stable power supply for the board’s signal processing and communication operations.

- Interface and Functional Parameters

- It is equipped with multiple specialized connectors including 3PL, JE, JB, JF and JG. The 3PL connector serves as a data bus to connect STCA, TCQA and TCQE boards in the core. The JB connector is responsible for the transmission of 4 – 20mA signals, and the JF connector receives LVDT/LVDR position inputs.

- It is configured with hardware jumpers such as J1, J2, J7 and J8. J1 and J2 are used to select the mA output circuit, J7 is dedicated to card testing through the RS232 port, and J8 is used to start the oscillator.

- It supports data interaction with the COREBUS, and the conditioned signals can be transmitted to the COREBUS through the 3PL connector to realize information sharing with the main control unit of the system.

Description

- Physical and Environmental Parameters

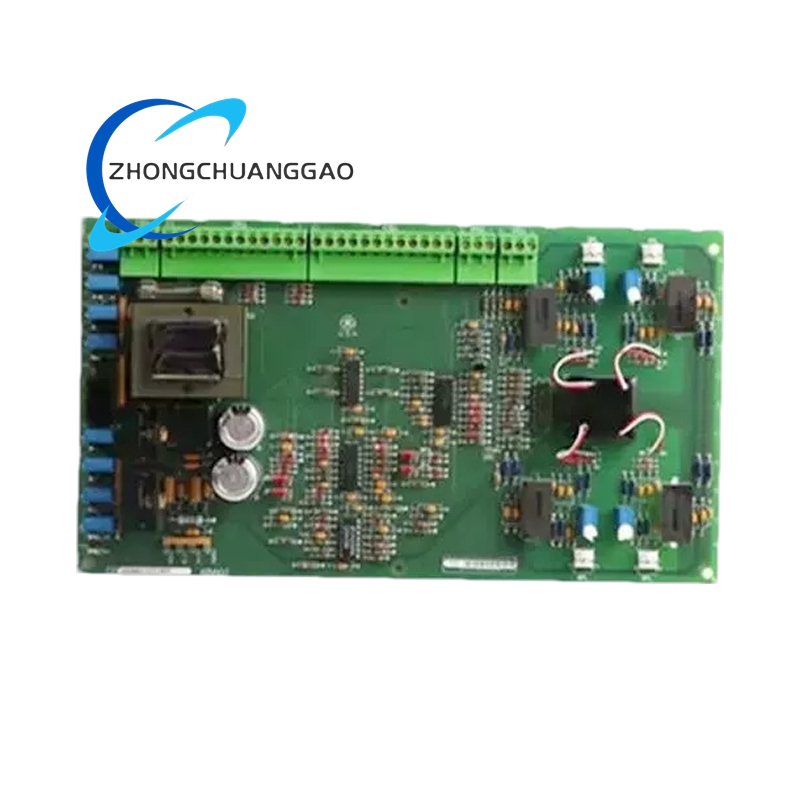

- It weighs 2.5 kilograms and has dimensions of 20cm × 25cm × 30cm, with a compact structure that fits the standard slot of the Mark V system cabinet for easy installation and layout.

- It has an operating temperature range of -40°C to 80°C, which can adapt to the high and low temperature changes of industrial sites. It can operate stably in an environment with a relative humidity of 5% – 95% without condensation.

- The board adopts high-quality electronic components and a sealed circuit design, which has good anti-interference performance and can resist electromagnetic interference in the industrial control environment.

Function Features

- Comprehensive Analog Signal Conditioning

The board can comprehensively scale and condition various analog signals generated during the operation of the gas turbine. It can accurately process special signals such as compressor stall detection signals and fuel flow pressure signals transmitted in the form of 4 – 20mA, converting these signals into standard signals that can be recognized and processed by the system’s main control unit, laying a foundation for the accurate control of the turbine.

- Targeted Connector and Jumper Configuration

The diversified connector configuration realizes the targeted transmission of different types of signals, avoiding signal confusion and interference. The dedicated hardware jumpers allow technicians to flexibly configure the board’s functional parameters according to actual application requirements. The RS232 port corresponding to J7 also provides a convenient way for board testing, ensuring the board’s performance meets the operation standards before installation and use.

- Stable Multi-Board Collaborative Work

Through the 3PL data bus connector, it establishes a stable connection with STCA, TCQE and other boards in the core, realizing efficient transmission and sharing of signals among multiple boards. The JD connector can send trip signals to the TCTG board in the core, forming a complete signal transmission chain, which ensures the coordinated operation of each component in the gas turbine control system and improves the overall stability of the system.

- Strong Adaptability to Industrial Signals

It covers almost all analog signals related to gas turbine operation, whether it is the position signal of mechanical components, the temperature signal detected by thermocouples, or the vibration signal reflecting the operating status of the equipment. It can handle them stably. This strong signal adaptability enables it to fully meet the signal processing needs of gas turbine control systems under different operating conditions.

Application Scenarios

- Gas Turbine Signal Processing in Thermal Power Plants

In thermal power plants equipped with Mark V series control systems, this board is installed in the gas turbine control cabinet. It processes the fuel flow pressure signals and compressor stall detection signals of the turbine. By conditioning these signals and transmitting them to the main control unit, it helps the main control unit accurately adjust the fuel supply volume and the operating state of the compressor, ensuring the stable power output of the gas turbine and improving the efficiency of power generation.

- Oil Refinery Gas Turbine Auxiliary Control

Oil refineries often use gas turbines to drive large – scale compressors and transfer pumps. This board is integrated into the supporting Mark V control system. It processes the vibration signals of the turbine and the position signals of the servo valve. The conditioned signals enable the control system to promptly find abnormal vibrations of the turbine and deviations in the servo valve position, and issue adjustment commands to avoid equipment damage caused by long – term abnormal operation.

- Metallurgical Plant Gas Turbine Status Monitoring

Some metallurgical plants use gas turbines as power sources for smelting auxiliary equipment. This board processes the thermocouple temperature signals and LVDT position signals of the turbine. It converts these analog signals into standardized signals and transmits them to the monitoring platform. The staff can understand the temperature changes of key parts of the turbine and the position status of mechanical components in real time through the monitoring platform, and carry out maintenance in advance when potential risks are found.

- Legacy System Maintenance in Chemical Plants

Many chemical plants still operate gas turbines with Mark V control systems. These turbines are used to drive reactors and material transportation equipment. When the original analog I/O board of the turbine control system fails and leads to signal distortion or transmission interruption, replacing it with the DS200FCRRG1AJD can quickly restore the signal conditioning and transmission function of the system, avoid long – term production suspension caused by equipment failure, and reduce economic losses.

- Marine Gas Turbine Control System Matching

Some large ships use GE Mark V series systems to control marine gas turbines. This board adapts to the harsh marine environment and processes the key signals of the marine gas turbine, such as the rotation speed pulse signal and the pressure signal of the exhaust gas. It ensures the reliable transmission of these signals to the main control system, which is essential for the stable operation of the marine gas turbine during navigation and guarantees the safety of the ship.

Reviews

There are no reviews yet.