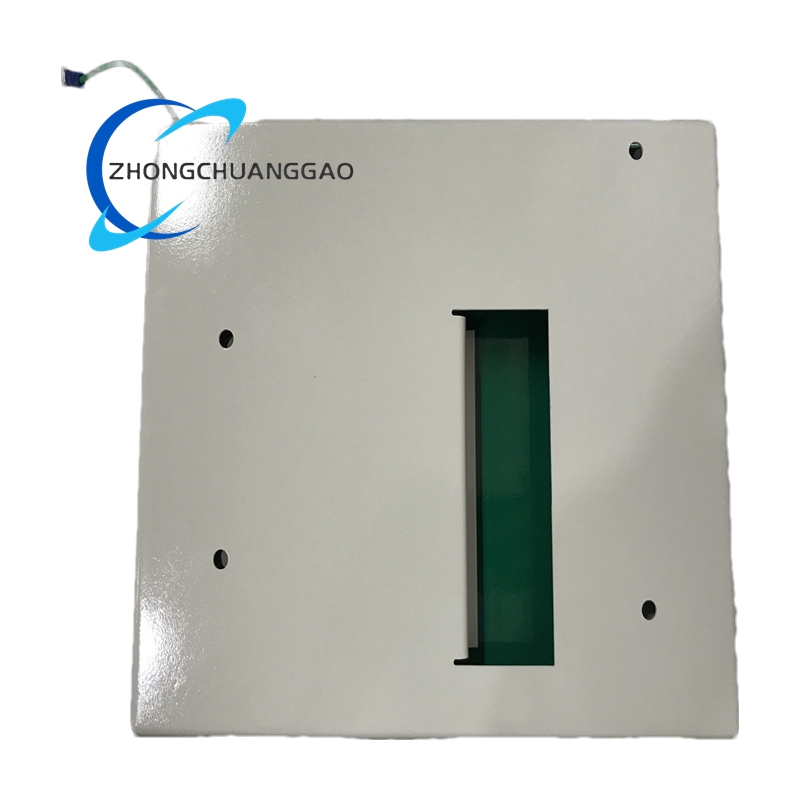

Product Short Description

Technical Specifications

- Mounting and Slot Parameters

- It supports two mounting methods, DIN rail mounting and panel mounting, which fits the installation habits of most industrial control cabinets and on-site equipment.

- It is equipped with 6 module slots to carry multiple I/O modules simultaneously and realize centralized management of multiple functional modules.

- Power and Communication Parameters

- It provides a stable 24 VDC power output with a power rating of 10 A, which is sufficient to supply power to all mounted modules and ensure their simultaneous and stable operation.

- It supports multiple communication protocols and interfaces including DeviceNet, RS-232, RS-485 and Ethernet, which facilitates seamless communication with upper-level control systems and lower-level field devices.

- Physical and Environmental Parameters

- It has a compact size of approximately 89 mm × 38 mm × 32 mm and a weight of only 200 grams, which occupies little space and is convenient for installation and layout in control cabinets.

- Its operating temperature range is from -40°C to 70°C, and the storage temperature range can reach -40°C to 85°C. It can adapt to relative humidity of 5% to 95% under non-condensing conditions.

Description

Function Features

- Flexible Configuration and Expansion

Its modular design and 6 dedicated slots allow users to select and install different types of I/O modules according to actual application needs. When the production scale expands or the control functions change, users can directly add or replace modules without replacing the entire carrier, which reduces transformation costs and improves the adaptability of the control system.

- Dual Configuration Support for High Reliability

It supports both simplex and redundant system configurations. In general industrial scenarios, the simplex configuration can meet the basic control needs with high cost-effectiveness. In key fields where system downtime is not allowed, the redundant configuration can realize mutual backup between modules. Once a fault occurs in one module, the backup module can immediately take over the work to ensure the continuous operation of the entire control system.

- Integrated Power Monitoring

It is equipped with an integrated power monitoring function that can real-time monitor the power supply status of the carrier and the mounted modules. When abnormal conditions such as voltage fluctuation and current overload occur, it can promptly send out alarm signals to remind maintenance personnel to handle the problem. This function effectively prevents equipment damage and system failures caused by power problems.

- Easy Installation and Maintenance

Field terminals can be directly inserted into the carrier without additional connectors or terminal wiring. This design simplifies the on-site installation process and shortens the construction cycle. At the same time, the clear slot division and standardized interface design make it easy for maintenance personnel to quickly locate faulty modules and replace them, which greatly reduces the difficulty and time of later maintenance.

Application Scenarios

- Automotive Manufacturing Industry

It is widely used in automated production lines such as automobile welding and assembly. It carries I/O modules connected to sensors and actuators on the production line. It controls the movement of robotic arms, the operation of conveying belts and the switching of assembly stations through centralized power supply and signal transmission. It ensures the precision and efficiency of each process in automobile manufacturing.

- Petrochemical Industry

It is applied in control systems of chemical reaction kettles, oil pipelines and other equipment in hazardous areas. It is connected with gas concentration sensors, pressure sensors and valve actuators through mounted I/O modules. It realizes real-time collection of on-site data and execution of control instructions. Its rugged structure and safety certification can avoid potential safety hazards caused by harsh on-site environments.

- Food and Beverage Processing Industry

It is integrated into production lines for beverage filling, food packaging and other processes. It carries modules related to temperature and flow control. It regulates the temperature of heating equipment and the speed of filling machines. It ensures that the production process meets food safety and hygiene standards, and maintains the consistency of product quality.

- Water Treatment Industry

It is used in urban sewage treatment plants and industrial wastewater treatment systems. It connects with liquid level sensors in sedimentation tanks, flow meters in water pipelines and dosing pump actuators via I/O modules. It controls the operation of water treatment equipment according to real-time water quality data, and ensures that the treated water meets the discharge standards.

- Energy Management Field

It is applied in HVAC systems and industrial energy monitoring systems. It carries modules responsible for collecting power consumption data and temperature and humidity data. It transmits the collected data to the upper-level energy management platform. It helps managers adjust the operation parameters of energy-consuming equipment in time to achieve the goal of energy conservation and emission reduction.

Reviews

There are no reviews yet.