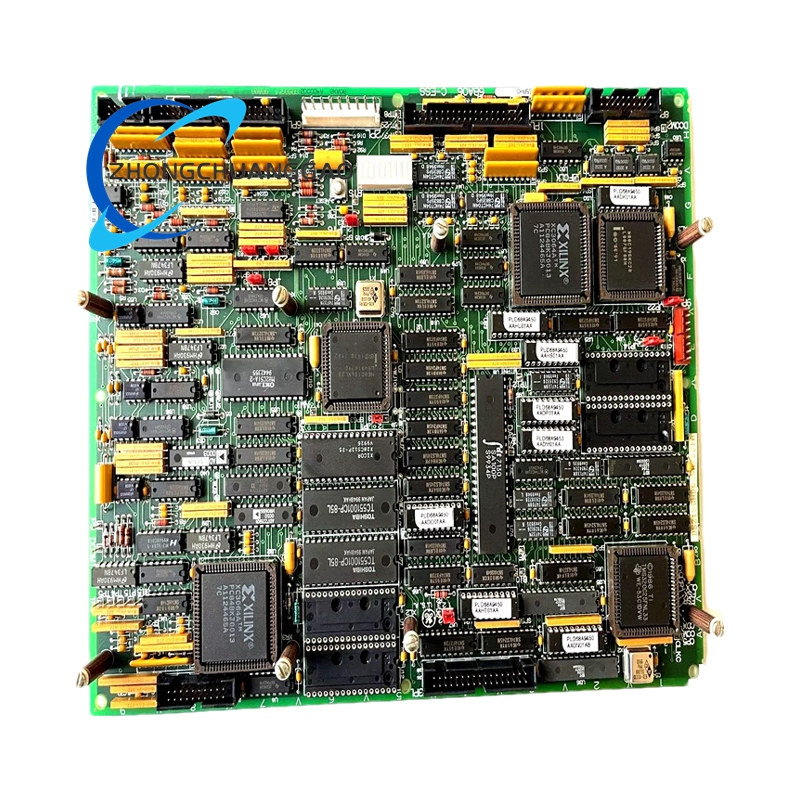

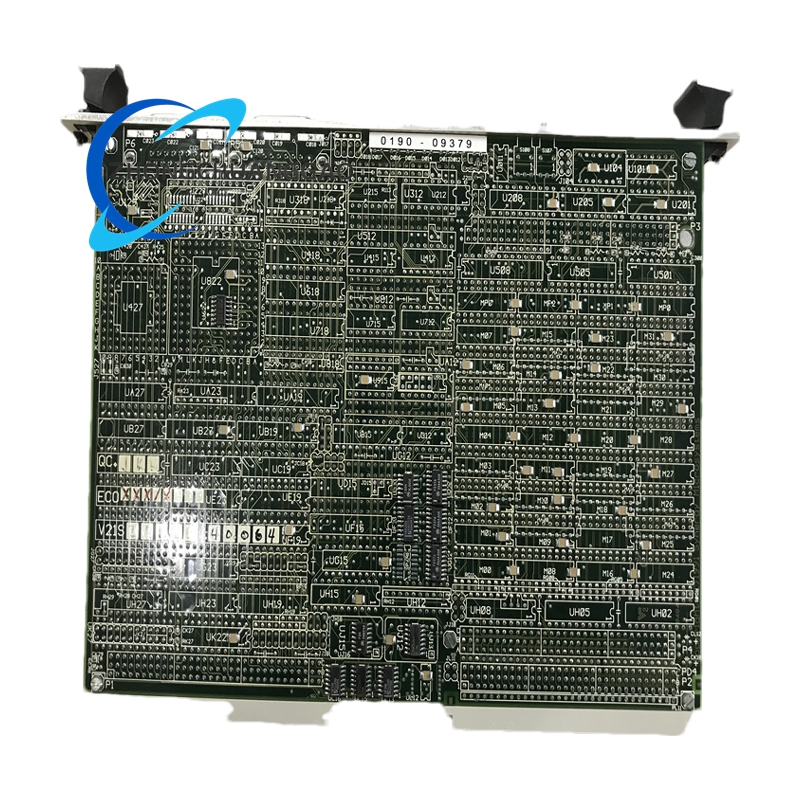

Product Short Description

Technical Specifications

- Power – Related Parameters

- It supports standard input voltages such as DC 24V or AC 110V, which are fully compatible with the power supply standards commonly used in most industrial automation sites.

- It provides stable power output for downstream components, and its internal circuit design suppresses voltage fluctuations, so that the output power can meet the continuous operation requirements of PLC modules, sensors and other equipment.

- The internal circuit is equipped with overload protection components, which can cut off the power supply in time when the load exceeds the rated value to avoid damage to the component itself and connected equipment.

- Physical and Interface Parameters

- It adopts a standard industrial modular size that fits VME or PCI slots, which can be seamlessly installed into standard industrial control cabinets and rack – mounted equipment without additional modification to the installation structure.

- It is equipped with matching interfaces such as VME or PCI, which realize stable connection with the main control unit and peripheral equipment of the industrial control system and ensure smooth data transmission and signal interaction.

- The overall weight is designed to be lightweight, which reduces the burden on the installation rack and facilitates staff to carry and install during maintenance.

Description

- Environmental Adaptability Parameters

- It can operate normally in the industrial common temperature range of -20°C to +60°C, adapting to the temperature changes in workshops, power plants and other on – site environments.

- It has good anti – electromagnetic interference performance, which can resist the electromagnetic signals generated by surrounding high – power equipment and ensure that its own functions are not affected.

- It can withstand a relative humidity of 20% – 85% under non – condensing conditions, and can maintain stable performance in humid environments such as chemical plants and water treatment sites.

Function Features

- Stable Power Supply Guarantee

The component provides stable voltage output that meets industrial standards for the core components of industrial control systems such as CPU modules and I/O modules. It solves the problem of unstable equipment operation caused by on – site power grid fluctuations through internal voltage stabilization and filtering circuits, laying a solid foundation for the continuous and reliable operation of the entire industrial control system.

- Efficient Signal Processing and Conversion

Beyond its power supply function, it undertakes the task of processing and converting industrial on – site signals. It can convert the analog signals collected by sensors (such as temperature, pressure and flow signals) into digital signals that the PLC can recognize and process, and also convert the digital control signals output by the main controller into analog signals that can drive actuators, realizing the effective connection between the perception layer and the execution layer of the industrial control system.

- Strong Compatibility and Interoperability

It is not only perfectly compatible with GE’s own series of industrial automation systems and PLC systems but also can be matched and used with many other brand industrial control equipment through standardized interfaces and communication protocols. This strong compatibility enables it to be flexibly applied to various mixed – brand industrial control system transformation and upgrading projects, reducing the cost of system transformation.

- Convenient Maintenance and Replacement

The modular design is one of its prominent features. When the component fails, staff can quickly remove the faulty component from the slot and replace it with a new one without disassembling the entire control system. This greatly shortens the equipment downtime caused by maintenance and improves the overall operation efficiency of the production line.

- High Reliability and Durability

It is manufactured with high – grade industrial – grade electronic components, and undergoes strict quality testing before leaving the factory. It can resist the harsh conditions such as vibration, electromagnetic interference and temperature change on the industrial site, and has a long service life. This high reliability reduces the frequency of component replacement, lowers the operation and maintenance cost of the enterprise.

Application Scenarios

- Industrial Automation Production Lines

It is widely used in the automatic control systems of various manufacturing production lines, including automobile manufacturing, electronic component production, textile printing and dyeing and plastic molding. It provides power and signal processing support for the PLC systems controlling robotic arms, conveyor belts and automatic processing machines, ensuring the precise coordination of each equipment on the production line and improving production efficiency and product quality consistency.

- Petroleum Industry

It is applied to the automation control systems in oil exploration, drilling and processing links. In oil drilling platforms and refineries, it supplies power to the control components of oil pumps, valves and pipeline pressure detection equipment, and processes the collected pipeline pressure, oil flow and other signals. It can operate stably in the harsh on – site environment with large temperature differences and high humidity, ensuring the safe and efficient operation of the oil production and processing process.

- Energy Industry

It plays an important role in the control systems of energy equipment such as gas turbines and hydropower generators in power plants. It provides stable power for the monitoring and control modules of these large – scale energy equipment, and participates in the processing of key parameters such as the operation speed and output power of the equipment. It helps the central control system to grasp the equipment operation status in real time and ensure the stable output of energy.

- Water Treatment and Environmental Protection Equipment

In the automatic control systems of water treatment plants and environmental protection equipment, this component provides support for the control of water pumps, chemical dosing devices and water quality detection sensors. It processes the water quality index signals collected by the sensors and transmits them to the main control system, and at the same time provides power for the execution components, ensuring the normal operation of water purification, sewage treatment and other processes.

- Legacy Industrial Control System Maintenance

Many old industrial control systems that have been put into operation for a long time still rely on GE’s early – generation PLC and automation equipment. GE 0190 – 09379 serves as a key spare part for these legacy systems. When the original components are aged or faulty, replacing them with this component can avoid the situation that the entire system has to be updated due to the lack of spare parts, which extends the service life of the legacy systems and saves a lot of renovation costs for enterprises.

Reviews

There are no reviews yet.