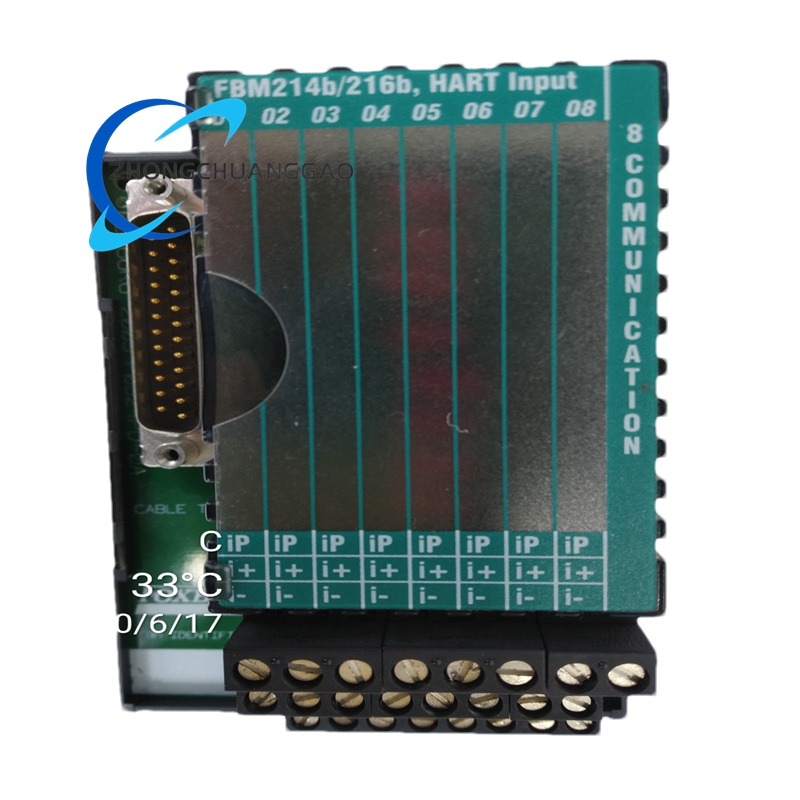

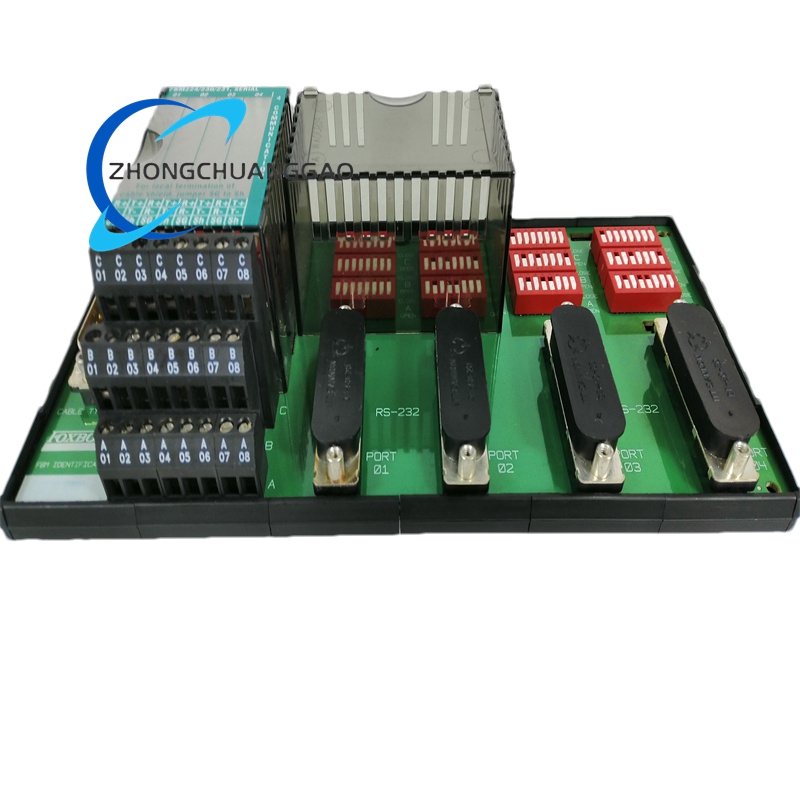

Product Short Description

Technical Specifications

-

- Electrical Parameters

- It supports a wide power supply range of 12 – 48V DC, which is compatible with various power configurations in industrial control systems and enhances its versatility in different application scenarios.

- It is equipped with multiple analog and digital input channels, provides a standard 4 – 20mA DC output signal, and achieves a measurement accuracy of ±0.1% full scale to ensure the precision of signal conversion and transmission.

- It has a maximum output frequency of up to 10kHz and can complete high-speed signal collection and processing, meeting the requirements of high-response industrial control scenarios.

- It supports multiple communication protocols including Modbus RTU, Ethernet, and Profibus, enabling seamless data exchange with different types of industrial control equipment and systems.

- Physical Parameters

- It has compact dimensions of 120mm × 60mm × 30mm and a light weight of 0.2kg, which takes up little space and facilitates dense installation in control cabinets along with other modules.

- It has an IP66 protection level, which can effectively prevent dust intrusion and splashing water damage, protecting internal electronic components from harsh on-site environmental factors.

- Electrical Parameters

Description

- Environmental Parameters

- Its operating temperature range extends from -40°C to 85°C, allowing it to operate normally in extreme cold or high-temperature industrial sites such as outdoor oil and gas pipelines and high-temperature chemical workshops.

- It can work stably in an environment with a relative humidity of 5% – 95% without condensation, adapting to humid working conditions like water treatment plants.

Function Features

- Dual Signal Compatibility and High – Precision Processing

The module supports both analog and digital input signals, which can be matched with various on-site sensors and switch devices. It conducts filtering and linearization processing on the collected signals to remove noise and signal distortion caused by on-site interference. With a measurement accuracy of ±0.1% full scale, it ensures that the data transmitted to the upper-level system truly reflects the operating status of on-site equipment and processes.

- Multi – Protocol Communication and Flexible Interconnection

By supporting multiple mainstream industrial communication protocols such as Modbus RTU, Ethernet, and Profibus, the module breaks the compatibility barriers between different brands and types of control equipment. It can be quickly integrated into existing industrial control systems without major modifications to the original system, realizing efficient data sharing and collaborative operation between devices.

- Fault Detection and Easy Maintenance

It is equipped with a dedicated fault detection function. When signal collection errors, communication interruptions, or internal component malfunctions occur, the module can immediately send out alarm signals to notify operators. Some configurations of the module support hot – swapping, allowing operators to replace or add modules while the system is running, which reduces system downtime and simplifies maintenance work.

- Scalable Design for System Expansion

The module can be flexibly expanded according to the scale of the control system. When the number of on-site devices increases and the original module configuration cannot meet the signal collection needs, it can be expanded through expansion modules. If expansion still fails to meet the requirements, it can also adopt a network structure to expand the overall capacity of the system, adapting to the expansion of production scale and changes in process requirements.

Application Scenarios

- Oil and Gas Industry

It is deployed in oil drilling platforms, refineries, and long-distance gas transmission pipelines. It collects signals from pressure sensors on pipelines, temperature sensors in oil storage tanks, and flow sensors in transmission pumps. It transmits the processed data to the central control system, which adjusts the operation of valves and pumps in a timely manner to prevent risks such as pipeline overpressure, oil leakage, and ensure the safety and efficiency of oil and gas extraction, refining, and transportation.

- Chemical Industry

It is installed in chemical production workshops, connecting with sensors that monitor parameters such as reaction temperature in reactors, material concentration in mixing tanks, and pressure in distillation equipment. It accurately collects and transmits these key process signals to the DCS. The system relies on these data to regulate the feeding speed and reaction time, ensuring that chemical reactions proceed as preset and avoiding safety accidents caused by parameter deviations.

- Manufacturing Industry

It is applied in automated production lines such as automobile manufacturing and electronic component processing. It matches with servo mechanisms on robotic arms, position sensors on assembly lines, and speed sensors on conveying equipment. It achieves precise control of the movement trajectory of robotic arms and the conveying speed of production lines by interacting with servo systems. It improves the coordination and accuracy of each link in the production line and enhances overall production efficiency and product quality.

- Power Industry

It is used in thermal power plants and hydropower stations, responsible for collecting signals from temperature sensors of boiler furnaces, pressure sensors of steam turbines, and flow sensors of cooling water systems. It transmits standardized data to the central control platform, which adjusts fuel injection volume and cooling water flow according to the data to maintain the stable operation of power generation equipment and ensure the continuous and reliable supply of power to the power grid.

- Food and Beverage Industry

It is integrated into food and beverage production lines such as dairy processing and beverage filling. It collects signals from temperature sensors in pasteurization equipment, concentration sensors in ingredient mixing tanks, and flow sensors in filling pipelines. It ensures that parameters such as sterilization temperature and filling volume meet process standards. It helps maintain the uniform taste and quality of products and complies with strict food safety production regulations.

Reviews

There are no reviews yet.