Product Short Description

Technical Specifications

- Electrical Parameters

- It adopts a 24V DC power supply, with a power consumption ranging from 8.5W to 10W, which is compatible with the universal power configuration of industrial control systems.

- It is equipped with 16 analog input channels, supporting input signal ranges of -10V to +10V for voltage and -20mA to 20mA for current, and provides a standard 4 – 20mA DC analog output signal.

- It has a signal resolution of 16 bits and a signal accuracy of up to ±0.1%, with a signal update cycle of 250ms, ensuring high-precision and real-time signal collection and transmission.

- It is configured with 16MB SDRAM and 32MB Flash memory, which can store a large amount of collected signal data and basic control program codes.

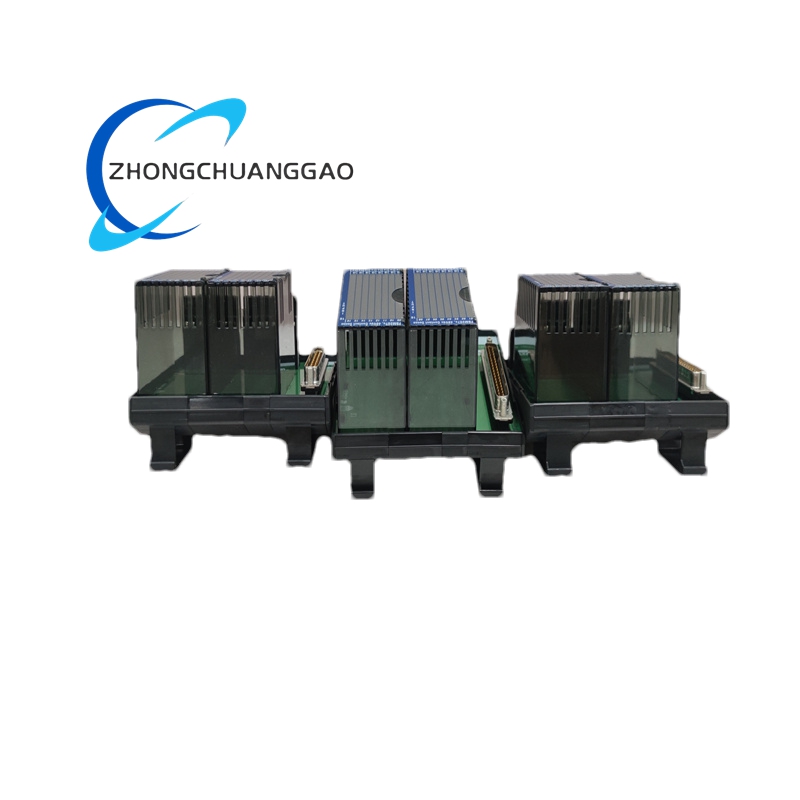

- Physical Parameters

- It has ultra-compact dimensions of 35mm × 25mm × 15mm, which occupies minimal space and facilitates dense installation in control cabinets alongside other modules.

- It features an IP66 protection level, which effectively isolates dust and prevents the intrusion of splashing water, protecting internal electronic components from damage in harsh on-site environments.

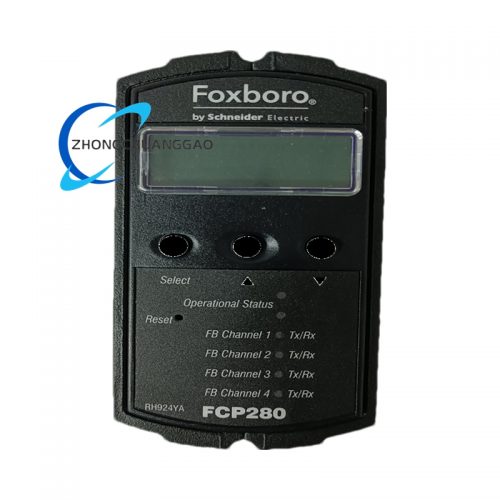

Description

Function Features

- Multi-type Signal Adaptability

The module supports multiple types of analog input signals including voltage and current. It can be flexibly matched with various common industrial sensors such as temperature transmitters and pressure sensors. This eliminates the need for additional signal conversion accessories, simplifying the system configuration and reducing equipment deployment costs while meeting diverse signal collection needs of different industrial processes.

- High-precision and Real-time Data Processing

With 16-bit resolution and an accuracy of up to ±0.1%, the module can capture subtle changes in on-site process parameters. The 250ms signal update cycle ensures that the upper-level control system can obtain the latest on-site data in a timely manner. This high-precision and real-time performance is critical for production processes that require strict parameter control, such as pharmaceutical preparation and chemical reactions.

- Easy Integration and Expansion

It adopts a modular design that is highly compatible with Foxboro’s I/A Series DCS and other industrial automation equipment. It can be quickly integrated into existing control systems without major modifications to the original system. Additionally, the modular structure allows users to increase or decrease the number of modules according to production scale expansion or process adjustments, enhancing the scalability of the entire control system.

- Strong Environmental Adaptability

The combination of IP66 protection level and a wide temperature and humidity operating range enables the module to resist the impact of harsh factors such as dust, humidity, and temperature fluctuations on-site. It maintains consistent performance in various complex industrial environments, reducing the frequency of module failures and the maintenance workload for on-site personnel.

Application Scenarios

- Petrochemical Industry

It is installed in oil refineries, natural gas processing plants, and pipeline transportation systems. It collects analog signals from pressure sensors on oil and gas pipelines, flow sensors in distillation towers, and temperature sensors in storage tanks. It transmits the processed signals to the I/A Series DCS, allowing the central control system to accurately monitor the entire process of oil refining and gas transmission and regulate relevant equipment in a timely manner to avoid safety risks such as pipeline overpressure and material leakage.

- Pharmaceutical Industry

It is applied in automated pharmaceutical production lines, connecting with sensors that monitor parameters such as mixing speed of pharmaceutical raw materials, temperature of sterilization equipment, and filling flow rate of finished products. It ensures that all key parameters in the production process are accurately collected and fed back to the control system. This enables the system to adjust equipment operation parameters in real time, ensuring that each production link complies with pharmaceutical quality standards and improving the qualification rate of pharmaceutical products.

- Power Industry

It is deployed in thermal power and hydropower plants, responsible for collecting signals from temperature sensors of boilers, pressure sensors of steam turbines, and flow sensors of water supply systems. It converts these signals into standardized data and transmits them to the central control platform. The platform relies on these data to adjust fuel injection volume, water supply flow, and other parameters, maintaining the stable operation of power generation equipment and ensuring the continuous and reliable supply of power to the power grid.

- Food Processing Industry

It is used in food production lines such as beverage filling and dairy processing. It connects with sensors that monitor the temperature of food cooking equipment, the concentration of ingredients, and the flow rate of filling pipelines. It ensures that parameters such as heating temperature and ingredient proportion meet process requirements during food production. This helps maintain the uniform taste and quality of food products and complies with food safety production specifications.

- Water Treatment Industry

It is installed in urban sewage treatment plants and industrial wastewater treatment systems. It collects signals from pollutant concentration sensors in sedimentation tanks, flow sensors in filtration equipment, and pH value sensors in dosing systems. It transmits the data to the central control system, which then precisely regulates the operation of dosing pumps and filtration equipment according to the data, ensuring that the treated water meets environmental discharge standards and improving the efficiency of water purification.

Reviews

There are no reviews yet.