Product Short Description

Technical Specifications

- Input Performance Parameters

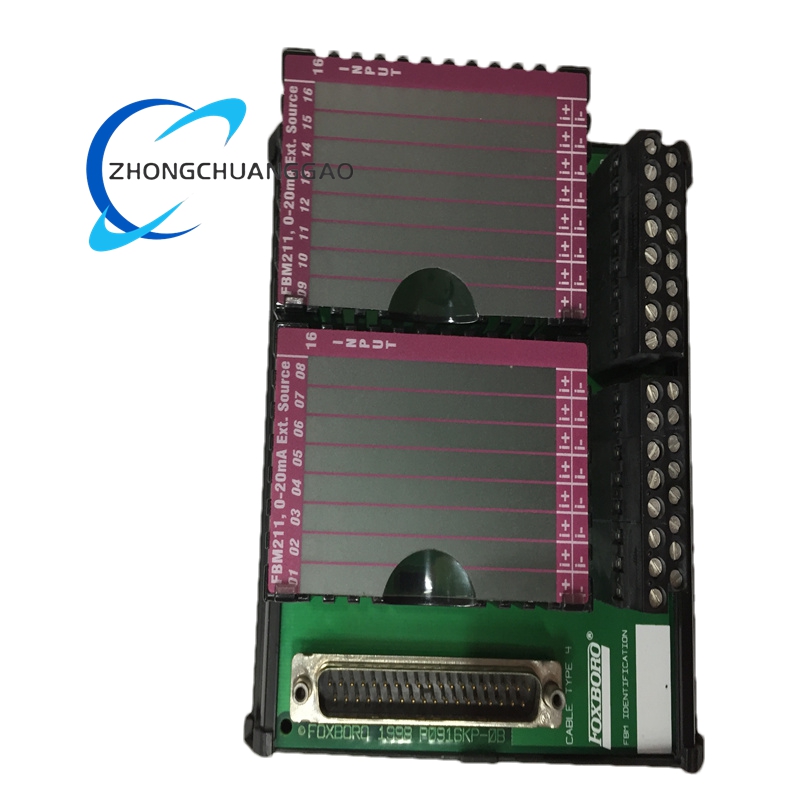

- It is equipped with 16 independent and isolated input channels, and each channel adopts a two-wire connection mode to connect with analog sensors such as 4-20mA transmitters.

- The input current range covers 0 to 20.4mA DC, and each channel is current-limited to a maximum of 33mA to avoid damage caused by excessive current.

- It achieves a measurement accuracy of ±0.03% of span, with an accuracy temperature coefficient of ±50 ppm/°C, and the signal update rate reaches 125ms to ensure real-time data collection.

- It has common mode rejection greater than 100dB at 50 or 60Hz and normal mode rejection greater than 35dB at the same frequency, and the nominal input channel impedance is 61.9Ω.

Description

- Physical & Environmental Specifications

- The shipping weight of the module is 2kg, and its compact size is conducive to installation in control cabinets with limited space.

- The module operates stably at -20°C to +70°C, and its matching PVC termination assembly works at -20°C to +50°C. The storage temperature range is -40°C to +70°C.

- It adapts to 5% – 95% non-condensing humidity environment, and can operate normally at an altitude of -300m to +3000m, and be stored at an altitude of -300m to +12000m. It can resist vibration of 0.75m/s² within the frequency range of 5 – 500Hz.

Function Features

- High-Precision Signal Conversion and Processing

Each channel uses a multiplexed sigma-delta converter for A/D signal conversion, and the integration period of the conversion process can be configured through software. This design ensures that the analog signals collected from the field are converted into digital signals with high precision and low noise, and the ±0.03% span accuracy meets the strict requirements of industrial process for signal measurement accuracy.

- Full Isolation Design for Anti-Interference

All 16 input channels are galvanically isolated from the ground and the module logic. This isolation design completely avoids signal crosstalk between channels and prevents damage to the module circuit caused by external voltage fluctuations or interference. It can effectively suppress electromagnetic interference in complex industrial environments and ensure the stability and purity of input signals.

- Redundant Design Ensures Uninterrupted Operation

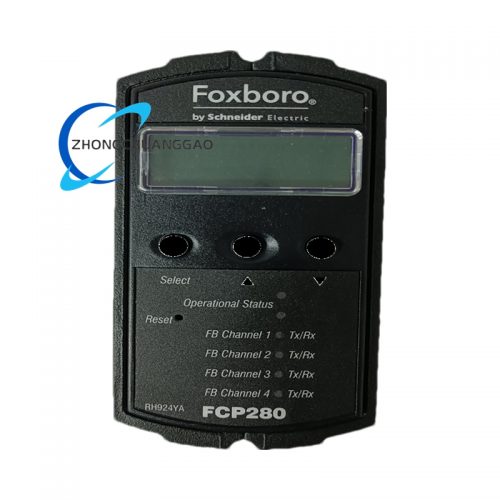

The module adopts redundant power supply and redundant fieldbus communication design. The redundant power supply avoids power failure caused by a single power supply fault, and the redundant communication bus ensures that data transmission will not be interrupted when a single communication path fails. This dual redundancy design greatly improves the reliability of the module and meets the requirements of continuous operation of industrial control systems.

- Flexible Configuration and Easy Operation

It supports configuration of conversion time and rate-of-change limits of analog signals through software, and is compatible with graphical configuration tools. Operators can adjust the module parameters according to different on-site sensor types and control requirements. It also supports real-time update cycle drawing, which is convenient for operators to monitor the signal changes of each channel in real time.

- Strong Environmental Adaptability

It meets the use standards of G3-class harsh environments, and has NEMA 4X protection level. It can resist the influence of dust, humidity and other harsh factors on the industrial site. Its wide operating temperature range and strong vibration resistance enable it to maintain stable performance in extreme working conditions such as cold regions and high-vibration workshops.

Application Scenarios

- Oil and Gas Industry

It is installed in upstream drilling platforms, midstream oil and gas transmission pipelines and downstream refining plants. It connects with pressure and flow transmitters on pipelines and storage tanks to collect 4-20mA signals reflecting oil and gas pressure and flow. The module transmits processed data to the DCS, which adjusts the opening of valves and the speed of pumps in time to ensure the safety and efficiency of oil and gas extraction, transmission and refining processes.

- Chemical Industry

It is deployed on key equipment such as reactors, distillation towers and dosing systems in chemical plants. It collects analog signals from temperature and concentration sensors in the reaction process. The control system adjusts the heating power and dosing amount according to the data transmitted by the module to ensure that chemical reactions proceed according to the preset process, avoid dangerous accidents caused by excessive temperature or unqualified concentration, and ensure the consistency of product quality.

- Power Industry

It is applied to coal-fired, gas-fired and other power plants, and is connected with temperature, pressure and flow sensors on boilers, steam turbines and generators. It monitors parameters such as boiler furnace temperature, steam pressure and generator winding temperature in real time. The data is transmitted to the central control system to guide operators to adjust fuel supply and cooling system operation, ensuring the efficient and safe operation of power generation equipment and preventing equipment damage due to abnormal parameters.

- Pharmaceutical Industry

It is used in pharmaceutical production lines such as chemical synthesis and preparation filling. It collects signals from temperature and pressure sensors in drug reaction kettles and concentration sensors in solution mixing tanks. It helps the control system strictly control the reaction conditions of drugs, ensuring that each production link meets GMP standards, and improving the stability and qualification rate of pharmaceutical products.

- Automated Manufacturing Industry

It is integrated into automated production lines such as automobile assembly and electronic component processing. It connects with position and pressure sensors on robots and processing equipment to collect signals reflecting the operation status of equipment. It ensures that the robots and processing equipment move accurately according to the set procedures, and triggers an alarm in time when the parameters are abnormal, so as to reduce production errors and improve the efficiency of the production line.

Reviews

There are no reviews yet.