Product Short Description

Technical Specifications

- Channel & Signal Parameters

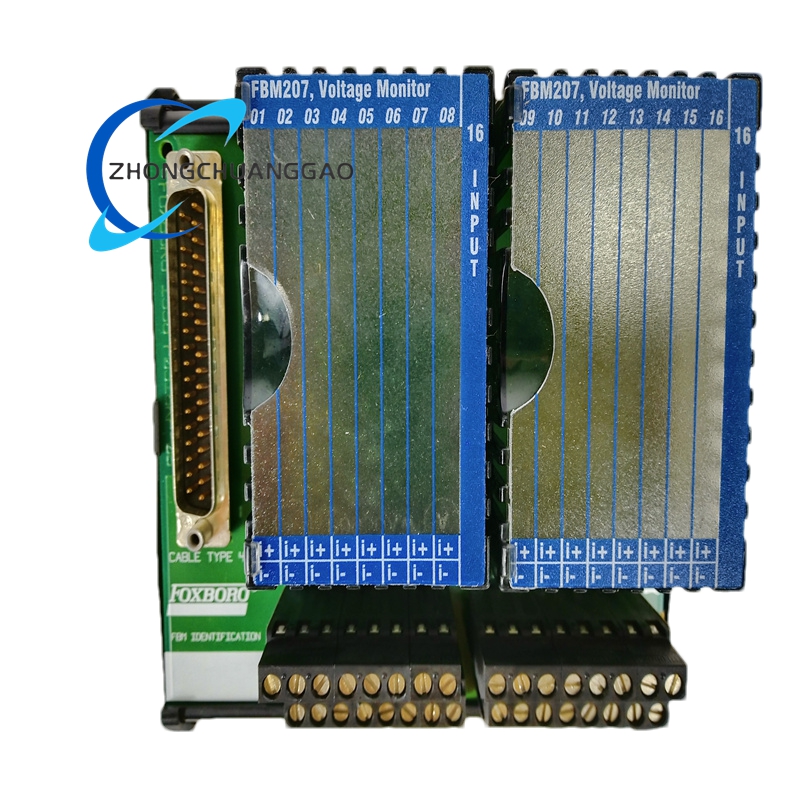

- It is configured with 16 discrete input channels, which can be used as either DC voltage monitors or contact sensors to meet large-scale on-site signal acquisition needs.

- It supports multiple voltage-level discrete signals, including 15 – 60V DC for contact sensing, 120V AC/125V DC and 240V AC for voltage monitoring or switch input.

- Electrical & Communication Specifications

- Each input channel is galvanically isolated, which completely avoids signal crosstalk between channels and prevents damage to the module caused by voltage interference.

- It adopts 24V DC as the nominal power supply, with a maximum power consumption of 8.5W for each non-redundant module.

- It communicates with the control system via a redundant 2Mbps module fieldbus, which ensures uninterrupted data transmission when a single communication path fails.

Description

- Physical & Environmental Specifications

- The module weighs 880g, and the size is 14.7cm × 5.15cm × 11.4cm, featuring a compact structure that saves installation space in the control cabinet.

- It can work stably within the operating temperature range of 0°C to 60°C, and adapts to an environment with 5% – 95% non-condensing humidity, meeting G3-class harsh environment operation standards.

- It is equipped with 16MB SDRAM and 32MB Flash memory, which provides sufficient storage space for program operation and data temporary storage.

Function Features

- Multi-functional Program Execution Capability

The module can run various practical programs such as discrete input processing, ladder logic, pulse counting and sequence of events recording. This allows it to not only collect basic signals but also complete simple logic operations and data analysis on-site, reducing the computing load of the central control system and improving the overall response speed of the control system.

- Convenient Installation and Maintenance

It adopts a screwless push-in wiring method and color-coded terminals. The former enables quick wiring without additional tools, while the latter facilitates quick identification of different signal types, greatly improving wiring efficiency. It can be removed and replaced without disconnecting on-site equipment termination cables, power supplies or communication cables, which minimizes maintenance downtime.

- Dual Isolation for Stable Signal Transmission

In addition to the galvanic isolation between channels, its matching termination assemblies are also equipped with optical isolation and voltage attenuation functions. This dual isolation design can suppress electromagnetic interference and voltage spikes in complex industrial environments, filter out invalid noise signals, and ensure the integrity and stability of the collected and transmitted signals.

- Intuitive Operational Status Monitoring

It is configured with LED visual indicators that clearly display the operating status of the module and each channel. Operators can directly observe whether the module is running normally and whether the input signals are stable through the indicator lights, and quickly identify fault channels when an abnormality occurs, which shortens the fault troubleshooting time.

- Strong System Compatibility and Scalability

It can be seamlessly integrated with Foxboro’s I/A Series DCS, and can be used in both single and redundant module configurations. This flexibility allows the module to adapt to different scale control system requirements, whether it is a small-scale equipment monitoring system or a large-scale integrated industrial control network.

Application Scenarios

- Petrochemical Industry

It is deployed in oil refineries, natural gas processing plants and oil transmission pipelines. It connects with contact switches and voltage sensors on pumps, valves and storage tanks to monitor the on-off status of valves and the voltage stability of transmission equipment. The module transmits real-time data to the DCS to ensure the safety of oil and gas extraction, refining and transportation processes and prevent leakage accidents caused by equipment failure.

- Metallurgical and Steel Industry

In steelmaking and non-ferrous metal smelting workshops, it is installed on smelting furnaces, continuous casting machines and conveyor systems. It monitors the contact signals of limit switches on the conveyor and the voltage signals of heating equipment. It helps the control system adjust the operation speed of the conveyor and the heating power of the furnace in a timely manner, ensuring the continuity of the smelting process and the quality of metal products.

- Machinery Manufacturing Industry

It is applied to automated production lines, assembly robots and mechanical processing equipment. It collects contact sense signals of safety doors, limit switches and voltage signals of drive motors. It ensures that each process of the production line is carried out in an orderly manner, and triggers an emergency shutdown when the safety door is opened or the motor voltage is abnormal, so as to protect the safety of equipment and operators.

- Automotive Industry

In automobile assembly lines and parts processing workshops, it is used to monitor the operation status of various automation equipment such as welding robots, painting equipment and conveyor belts. It captures voltage signals of equipment drives and contact signals of position switches, and feeds back data to the control system to ensure the accuracy and efficiency of each assembly step and improve the qualification rate of finished automobiles.

- Light Industry

It is widely used in production lines of food and beverage, textile and other light industrial fields. In food processing lines, it monitors the voltage of temperature control equipment and the contact signals of packaging position switches; in textile mills, it collects voltage signals of spinning machines and contact signals of yarn breakage detection switches. It provides reliable data support for the stable operation of the production lines and ensures the consistency of product quality.

Reviews

There are no reviews yet.