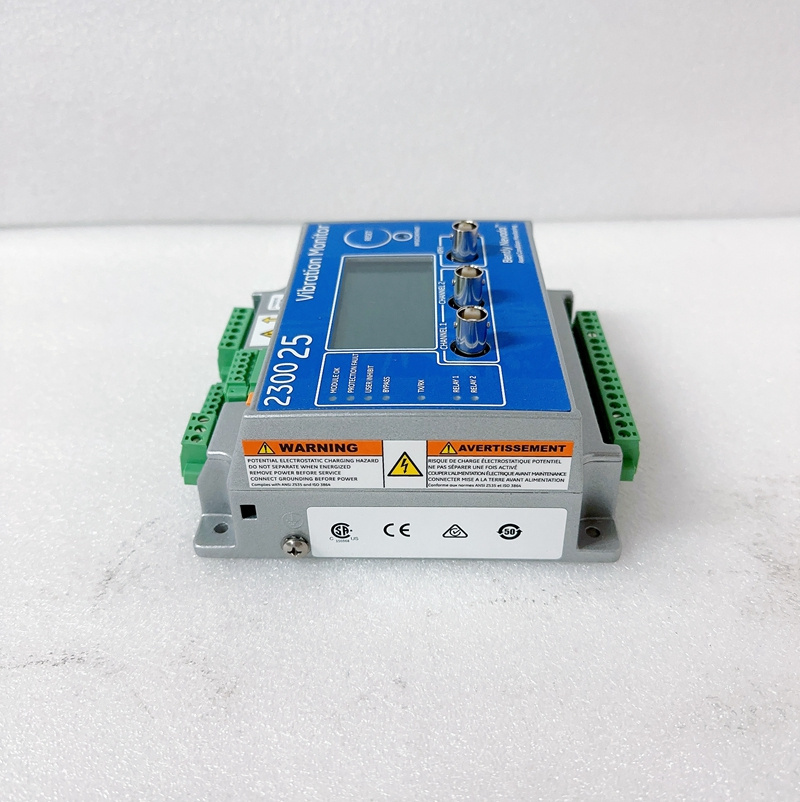

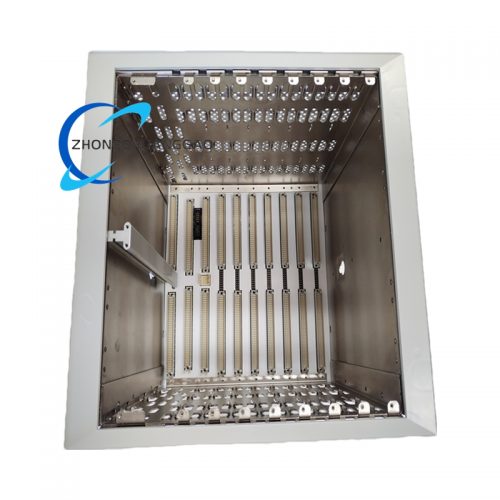

Product Short Description

Technical Specifications

- Power Input: DC input: 18 – 36VDC, maximum 7.5W.

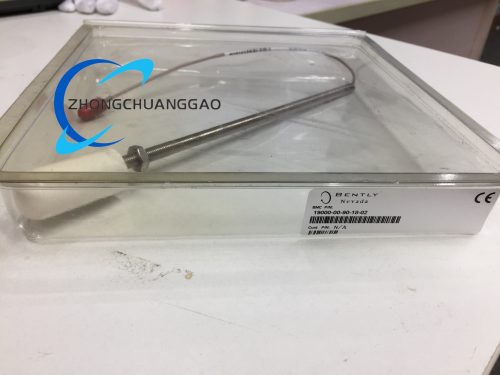

- Vibration Sensor Input: Supports ICP accelerometers with a pass – band variable of 0.2 Hz high – pass and 20 kHz low – pass, a sensitivity range of 5 to 575 mV/g, a range of 2 to 80 g peak, a bias voltage range of – 12VDC, a configurable OK voltage upper limit of – 0.25 to – 22 V, a configurable OK voltage lower limit of – 0.25 to – 22 V, a constant – current source supply current of 3.3 mA ± 5%, and an open – circuit voltage of – 21 to – 24 VDC. It also supports custom accelerometers (2 – wire or 3 – wire), and each channel has independent 24 – bit AD conversion.

Description

- Speed/Key – Phase Input: Supports eddy – current probes, proximity switches, and reluctance transmitters. It supports multi – event and single – event ratios per revolution, with a speed input of up to 20 kHz. The threshold voltage resolution is 0.1VDC. For eddy – current sensors, the supply voltage is – 22.8 to – 25.2 VDC, the maximum rated current is 15 mA, the short – circuit current is 15.1 to 23.6mA, the accuracy is ±1% of the range, and the input impedance is 10 kΩ in 3 – wire voltage mode, with a speed range of 1 to 120,000 RPM. For proximity switches, the supply voltage is – 10 to – 24 VDC, the non – Ok voltage lower limit is – 2.75 ±0.05 V, and the speed range is 1 to 120,000 RPM. For reluctance transmitters, the input voltage is up to ±125V (250Vp – p), and the speed range is 200 to 120,000 RPM.

- Relay Output: Two dry – contact relay outputs, which can be set to normally – energized or normally – de – energized. For non – hazardous area relay circuit technical specifications, the type is single – pole double – throw, sealed with epoxy resin, the contact life is 100,000 cycles @ 5 A 250 VAC, 200,000 cycles @ 1 A 24 VDC, the insulation impedance is at least 1000 MΩ @ 500 VDC, the relay closed – contact resistance is at most 1 Ω, the relay open – contact resistance is at least 1 MΩ, the maximum switching voltage is 250 VAC / 250 VDC, and the maximum breaking current is 6 A @ 250 VAC / 6 A @ 24 VDC.

- Dimensions and Weight: The dimensions are 263 × 138 × 88 mm, and the weight is 2.35 kg.

Function Characteristics

- Continuous Monitoring and Protection: It can continuously monitor the vibration of equipment and provide protection.

- LCD Display: The LCD display shows vibration amplitude, set values, and speed.

- Synchronous Sampling: The two acceleration vibration inputs can be synchronously sampled, which is convenient for advanced diagnostic analysis.

- Real – Time Alarm Configuration: Real – time alarm configuration for key measurement values (overall peak value, peak – to – peak value, overall RMS value, equivalent peak value, overall integral peak value, speed).

- Relay Output: Two programmable relay outputs can be used to trigger alarms or control other devices.

- Buffered Transducer Outputs: Three buffered transducer outputs (including speed signal) are provided, which have short – circuit and electromagnetic interference protection. Each signal’s buffered output is obtained through a BNC plug.

- Communication Interface: It has an Ethernet 10/100 Base – T communication interface, and Modbus® Ethernet communication is optional.

Application Scenarios

- Industrial Machinery Monitoring: Used to monitor the vibration of industrial equipment such as pumps, fans, generators, and gearboxes, and detect possible mechanical problems and faults.

- Power Industry: In power plants, it is used to monitor the vibration of rotating equipment such as turbines and generators and identify possible mechanical faults.

- Oil and Gas Field: In oil fields and gas facilities, it is used to monitor the vibration of pumps, compressors, and other rotating equipment to identify potential mechanical problems in advance.

- Manufacturing Industry: In the manufacturing process, it is used to monitor the vibration of important equipment to ensure the normal operation of the equipment and prevent potential faults.

- Transportation Industry: In the transportation fields such as railways, ships, and aircraft, it is used to monitor and maintain the vibration of key components to ensure the reliability of the transportation system.

- Wind Power Generation: In wind turbines, it is used to monitor the vibration status of rotating components to detect potential faults in a timely manner.

Be the first to review “Bently Nevada 2300/25-00” Cancel reply

Reviews

There are no reviews yet.