Product Short Description

Technical Specifications

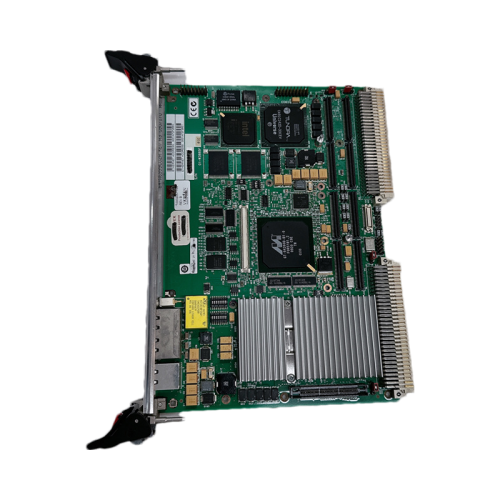

- Channels: 4-channel monitoring

- Input Signals: Accepts inputs from seismic sensors for vibration measurement

- Measurement Range: 0-20000 RPM (revolutions per minute)

- Accuracy: ±0.05% of full scale

- Output Signals: 4-20mA analog output, alarm relay outputs

- Sampling Rate: High-speed sampling for accurate signal capture

- Operating Temperature: -40°C to 85°C

- Power Requirements: 18-32VDC

- Dimensions: 127mm x 127mm x 254mm

- Protection Class: IP65 (dust-tight and protected against water jets)

Description

Key Features

- High Precision Monitoring: Provides extremely accurate speed and impulse measurements, ensuring reliable operation in various industrial environments.

- Wide Measurement Range: Capable of monitoring a broad range of speeds, adaptable to different reciprocating compressor applications.

- Multiple Input Options: Supports various sensor inputs, enhancing compatibility and flexibility in system integration.

- Alarm Functionality: Built-in alarm thresholds trigger alerts when monitored parameters exceed preset limits, enabling timely intervention.

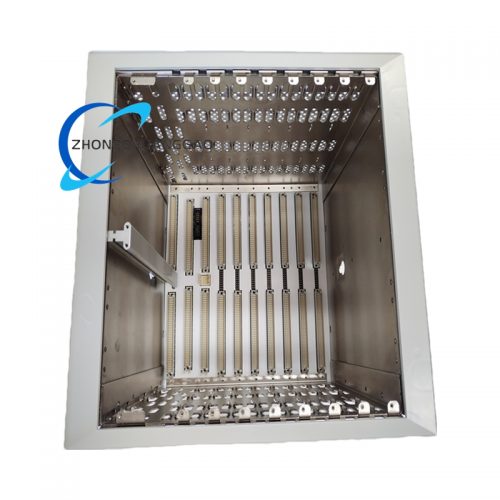

- Modular Design: Facilitates easy installation, maintenance, and upgrades, reducing downtime and operational costs.

- Robust Construction: Designed to withstand harsh industrial conditions, ensuring long-term stability and durability.

Functional Characteristics

- Continuous Monitoring: Continuously monitors the speed and impulse signals of reciprocating compressors, detecting anomalies early.

- Fault Diagnosis: Analyzes vibration patterns to identify potential faults, aiding in preventive maintenance and reducing unexpected failures.

- Data Analysis: Provides essential machine information for operation and maintenance personnel, supporting informed decision-making.

- Self-Diagnostics: Monitors its own operating status and sensor health in real-time, preventing false alarms or missed detections.

- Flexible Configuration: Each channel can be individually programmed to perform specific monitoring functions, offering customized solutions.

Application Scenarios

- Power Industry: Monitors the speed of turbines and generators to ensure safe operation and prevent failures due to over-speed or other anomalies.

- Petrochemical Industry: Used in the monitoring of compressors and pumps, ensuring efficient and safe operation in critical processes.

- Metallurgical Industry: Monitors the speed of rolling mills and fans, optimizing production efficiency and preventing equipment damage.

- Other Industries: Applicable in any scenario requiring precise speed monitoring of reciprocating machinery, such as in paper mills, refrigeration systems, and more.

Reviews

There are no reviews yet.