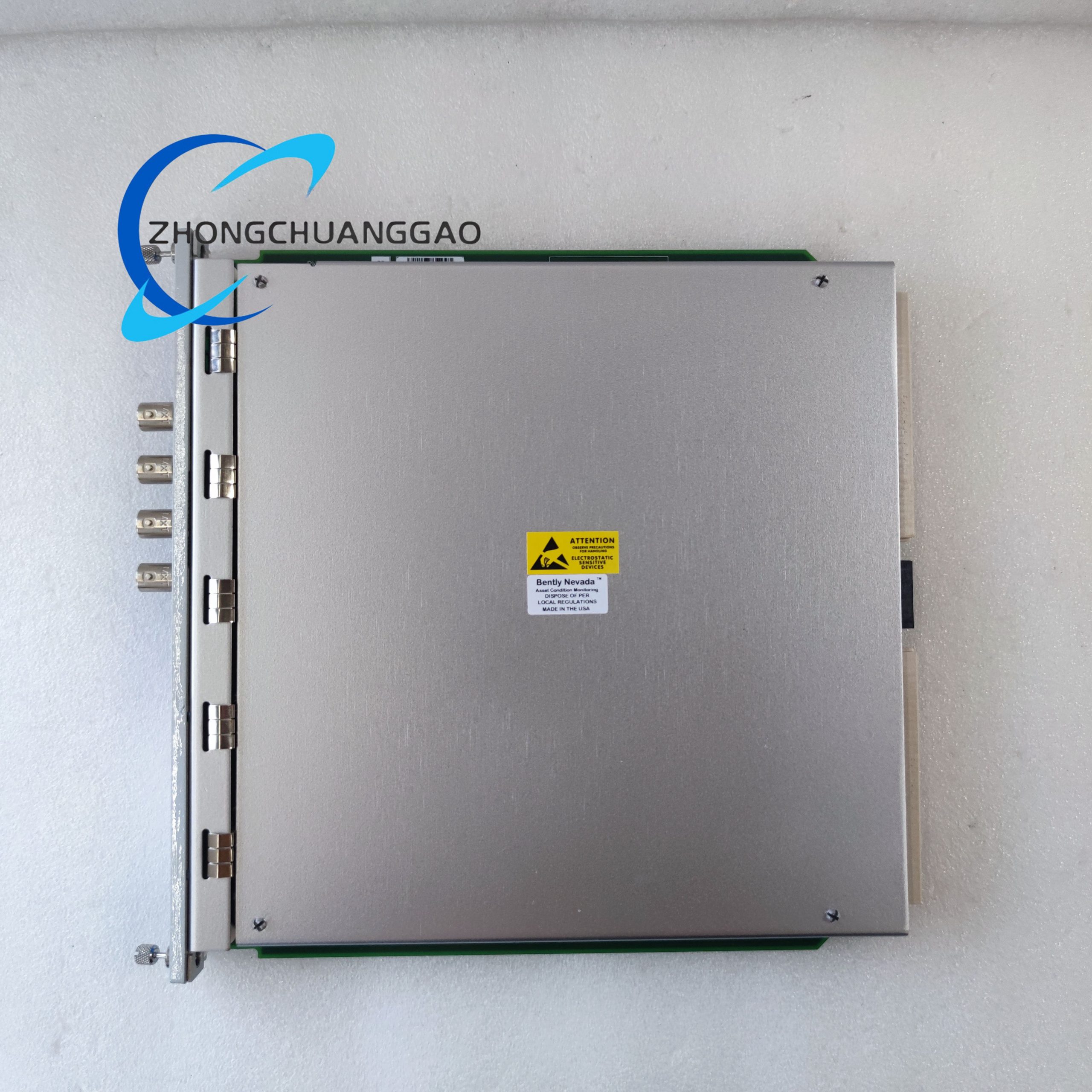

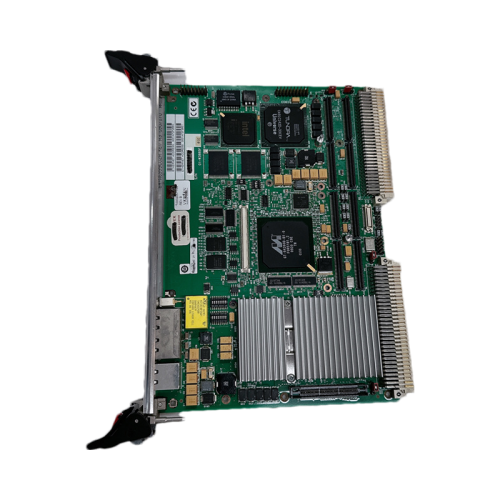

Product Short Description

Technical Specifications

- Channels: Four independent channels, each configurable for different measurement functions.

- Input Types: Accepts signals from various vibration sensors, including velocity sensors and accelerometers.

- Measurement Functions:

- Radial Vibration

- Axial Displacement

- Eccentricity

- Differential Expansion

- Signal Processing: Advanced signal processing capabilities, including signal integration, filtering, and amplification, to extract useful information and eliminate interference.

- Communication Protocols: Supports multiple communication protocols, such as Modbus and Ethernet, for seamless integration with other devices or systems.

- Environmental Rating: Designed to operate in harsh industrial environments with a wide temperature range and robust construction.

Description

Key Features

- High Precision and Reliability: The monitor uses high-quality electronic components and materials, ensuring accurate and reliable vibration measurements.

- Multi-Channel Monitoring: Supports simultaneous monitoring of multiple measurement points, providing comprehensive coverage of rotating machinery.

- Real-Time Alarming: When vibration levels exceed preset thresholds, the monitor can provide real-time alarms or shutdown protection to prevent equipment damage.

- Powerful Data Processing: Built-in data processing and analysis functions, such as frequency spectrum analysis and trend prediction, support preventive maintenance.

- Flexible Configuration: Each channel can be independently configured to meet specific application requirements, allowing for customized monitoring solutions.

- Easy Integration: Compatible with the Bently 3500 series monitoring system and supports various communication protocols, facilitating easy integration into existing control systems.

- Modular Design: The modular design simplifies expansion and maintenance, reducing downtime and operational costs.

Application Scenarios

- Power Generation: Monitors turbines and generators in power plants to ensure safe operation and prevent equipment damage due to excessive vibration.

- Oil and Gas: Protects compressors, blowers, and other rotating equipment in production facilities, ensuring continuous and efficient operation.

- Chemical Processing: Ensures the safe operation of machinery in chemical plants, preventing accidents caused by equipment failures.

- Manufacturing: Used for equipment status monitoring and preventive maintenance in large industrial machinery, improving production efficiency and reducing downtime.

- Aerospace: Specifically designed for aeroderivative gas turbines, the monitor provides accurate vibration monitoring to ensure the safe and reliable operation of these critical components.

Reviews

There are no reviews yet.