Product Short Description

Technical Specifications

- Channels: Four independent channels, configured as 2× displacement/acceleration and 2× velocity.

- Input Types:

- Displacement: Electro-hydraulic proximity sensors.

- Velocity: Seismic velocity sensors.

- Acceleration: Seismic acceleration sensors.

- Sensitivity Ranges:

- Radial Vibration: 3.94 mV/µm (100 mV/mil) or 7.87 mV/µm (200 mV/mil).

- Axial Displacement: 0.787 mV/µm (20 mV/mil).

- REBAM®: 40 mV/µm (1000 mV/mil) or 80 mV/µm (2000 mV/mil).

- Acceleration: 10 mV/(m/s²) (100 mV/g).

- Velocity: 20 mV/(mm/s) peak (500 mV/(in/s) peak) or 5.8 mV/(mm/s) peak (145 mV/(in/s) peak).

Description

- Filter Options: User-programmable filters including bandpass, low-pass, and notch filters to eliminate unwanted frequency components.

- Output Signals: Processed signals can be output as digital or analog signals for integration with other control or monitoring systems.

- Power Consumption: Normal consumption is 7.7 watts.

- Environmental Rating: NEMA 4/4X weatherproof enclosure for harsh environments.

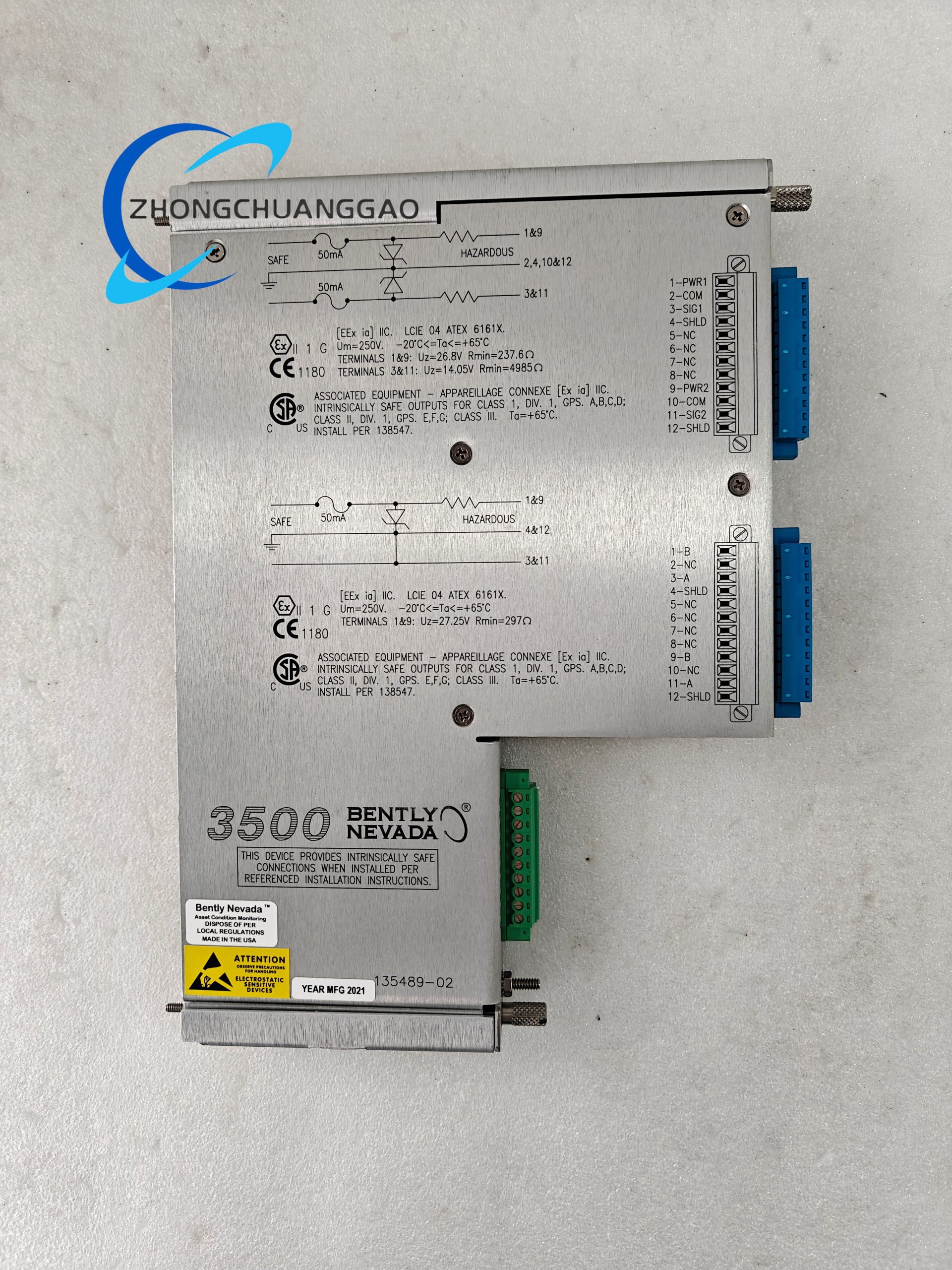

- Certifications: Meets API 670 standards for mechanical protection systems; optional ATEX, IECEx, and CSA certifications for hazardous areas.

Key Features

- Flexible Configuration: Each channel can be independently configured for displacement, velocity, or acceleration measurements using 3500 rack configuration software.

- High Reliability: Built with high-quality materials and manufacturing processes, subjected to rigorous testing and quality control to ensure stable operation in harsh industrial environments.

- Comprehensive Alarm Logic: Supports comprehensive alarm logic for each channel, enabling timely alerts for abnormal conditions.

- Seismic Monitoring: Supports seismic sensors for low-frequency vibration analysis, crucial for early fault detection in rotating machinery.

- Redundancy Support: Compatible with Triple Modular Redundant (TMR) systems for high-availability applications.

- Ethernet Connectivity: Enables integration with System 1 software for advanced data analysis and predictive maintenance.

- User-Friendly Interface: LED indicators for OK, TX/RX communication, and bypass status for easy monitoring of module status.

Application Scenarios

- Power Generation: Monitors turbines, generators, and pumps in power plants to ensure safe operation and prevent equipment damage.

- Oil and Gas: Protects compressors, blowers, and other rotating equipment in production facilities, ensuring continuous and efficient operation.

- Chemical Processing: Ensures safe operation of machinery in chemical plants, preventing accidents caused by equipment failures.

- Manufacturing: Used for equipment status monitoring and predictive maintenance in large industrial machinery, improving production efficiency and reducing downtime.

- Steel and Metals: Monitors rolling mills, fans, and other critical equipment, ensuring stable production processes.

- Pulp and Paper: Protects rotating machinery in paper production lines, preventing production interruptions due to equipment failures.

Reviews

There are no reviews yet.