Product Short Description

- Product Name

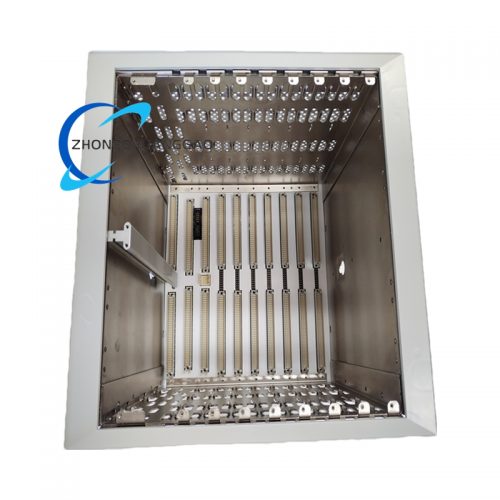

- 16-Channel Relay Output Module for Bently Nevada 3500 Series Machinery Protection System

- Product Introduction

This module is a full-height relay output component specially designed for Bently Nevada’s 3500 series machinery protection system. It focuses on providing reliable relay control and monitoring functions for industrial equipment. It integrates 16 independent relay output channels and serves as a key link between the 3500 series monitoring system and external control equipment. The module receives monitoring signals from the system, processes these signals through programmable logic, and converts them into relay actions to realize equipment protection and interlocking control. It can be seamlessly installed and connected to the 3500 series rack through the backplane, and its cost-effective design makes it suitable for general machinery and industrial processes that need continuous monitoring and protection. It effectively reduces the risk of unplanned downtime of equipment and provides stable guarantee for the safe and efficient operation of industrial production lines.

Description

- Technical Specifications

- Relay Configuration: It is equipped with 16 independent relay output channels. Each channel has a current rating of 1A, and the relay contact rating reaches 2A at 240VAC. It adopts solid-state relay technology with a normally open contact form.

- Power Supply: It adopts 24VDC power supply mode, which is fully compatible with the power supply system of the 3500 series rack and ensures stable power input for long-term operation.

- Response Performance: The relay response time is less than 1 millisecond, which can quickly respond to the alarm and fault signals from the monitoring system and realize rapid control of external equipment.

- Physical Specifications: The physical dimensions are 8.5 inches × 6.7 inches × 1.2 inches, and the net weight is 2.0 pounds. It supports DIN rail installation, which is consistent with the installation standards of the 3500 series modules and facilitates integrated assembly.

- Environmental Adaptability: It has an IP65 protection level and can operate stably in an environment with a temperature range of -40°C to +85°C. The rugged printed circuit board design and conformal coating can resist dust and humidity erosion.

- Communication Interface: It connects to the 3500 series rack through the backplane and supports Ethernet/IP and Profinet industrial standard communication protocols to realize data interaction with the upper-level control system.

- Function Features

- Programmable Logical Operation: It supports AND/OR logical programming for alarm-driven logic. It can integrate measurement variables from different channels of the 3500 system, process complex signal combinations, and customize relay action rules according to actual industrial control needs.

- Diversified Communication Compatibility: It supports Modbus communication through Ethernet and software-configurable RS232/485 serial ports. The optional Modbus gateway can directly transmit static variables, event lists and time-date information to Modbus clients such as distributed control systems and programmable logic controllers.

- Convenient Configuration and Maintenance: Users can create configuration files on a computer through professional configuration software and download them to the module via the built-in Ethernet connection. The non-volatile memory stores configuration information permanently, and the module supports remote diagnosis and maintenance to reduce on-site operation difficulty.

- Independent Channel Control: The 16 relay channels work independently without interfering with each other. Each channel can be configured according to different monitoring indicators and control objects to meet the multi-point control needs of complex industrial equipment.

- Self-diagnostic and Fault Tolerance: It has built-in self-test diagnostic functions that continuously monitor its own relay status and communication links. When abnormalities such as relay failure or communication interruption occur, it can promptly feed back fault information to the system to ensure the integrity of operational performance.

- Application Scenarios

- Power Industry: It is widely used in thermal power, hydropower and nuclear power plants to match with key equipment such as steam turbines and generators. When the system detects abnormal vibration or temperature, it triggers relays to cut off the relevant circuits or start standby equipment to avoid major power generation accidents.

- Oil and Gas Industry: It is installed on offshore drilling platforms, pipeline compressors and refinery equipment. It adapts to the harsh marine and onshore working environments, responds to equipment faults such as bearing wear and rotor imbalance, and guarantees the safety of oil and gas extraction, transportation and refining processes.

- Chemical Industry: It is applied to chemical reaction kettles, conveying pumps and air compressors in chemical plants. It links with the equipment monitoring system to control the opening and closing of valves and the start-stop of pumps through relay actions, preventing safety accidents caused by abnormal equipment operation.

- Railway Industry: It is deployed in railway locomotive maintenance and power supply systems. It monitors the operation status of locomotive engines and power transmission equipment. When faults are detected, it triggers timely alarms and protective actions to ensure the stable operation of railway transportation.

- Water Treatment Industry: It is used in municipal water pump stations and large water treatment equipment. It realizes 24-hour continuous monitoring of water pump vibration. It can quickly start standby water pumps through relay control when the main pump fails, ensuring the normal operation of the water supply system.

Reviews

There are no reviews yet.