Product Short Description

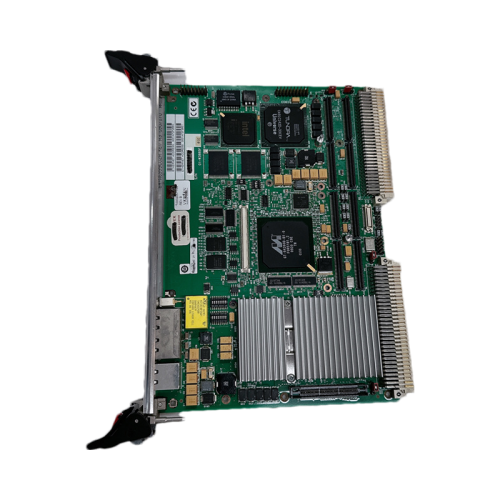

- Product Name

- 16-Channel Relay Output Module for Bently Nevada 3500 Series Machinery Protection System

- Product Introduction

This is a full-height relay output module exclusively developed for Bently Nevada’s 3500 series machinery protection systems and is manufactured in the USA. It acts as a vital link between the 3500 series monitoring system and external control equipment, featuring 16 independent relay channels to implement alarm triggering, emergency shutdown, and equipment interlocking functions. The module can be installed in any slot to the right of the transient data interface module in the 3500 rack, and it collaborates seamlessly with other modules in the series. It receives alarm, danger status, and other signals from various monitoring channels in the rack, processes these signals through pre-programmed logic, and activates corresponding relay actions. Its epoxy-sealed structure enables stable operation in harsh industrial environments with dust and moisture, and it is widely used to safeguard the safe operation of large and medium-sized rotating machinery in multiple industrial sectors.

Description

- Technical Specifications

- Relay Configuration: Equipped with 16 single-pole double-throw relays. Each relay is fitted with a 250Vrms arc suppressor as a standard configuration, and the relay contact life can reach 100,000 operation cycles.

- Power Consumption: Runs with a typical power consumption of 5.8 watts, which is fully compatible with the power supply system of the 3500 series rack and ensures energy-efficient operation during long-term use.

- Environmental Performance: Operates within a temperature range of -30°C to +65°C and can be stored in an environment ranging from -40°C to +85°C. It works normally in an environment with 95% non-condensing humidity, and the epoxy-sealed design enhances its resistance to dust and moisture.

- Physical Dimensions: Measures 2.6 centimeters ×25.6 centimeters ×24.4 centimeters and has a net weight of 0.4 kilograms. The compact size allows it to be easily integrated into the 3500 series rack without occupying excessive space.

- Panel Indicator: Equipped with an OK LED on the front panel. The LED stays illuminated when the module operates normally, enabling on-site staff to quickly check the module’s working status.

- Function Features

- Independent Programming with Voting Logic: Each of the 16 relay outputs can be independently programmed to execute the required voting logic. This flexibility allows the module to adapt to complex control requirements in different industrial scenarios and precisely match the operational needs of various machinery.

- Flexible Alarm Drive Logic: Each relay integrates alarm drive logic and supports “AND” and “OR” logic programming. It can trigger relay actions based on alarm inputs, non-normal status signals from any single monitoring channel or combined monitoring channels in the rack, achieving targeted responses to different equipment fault conditions.

- Highly Compatible Modular Design: The modular structure enables the module to be placed in any slot of the 3500 rack interface module. Users can install any number of these modules according to the scale of the monitoring system, realizing the expansion of relay output channels and building efficient and scalable control systems.

- Diverse Signal Adaptability: Supports eddy current sensors and electromagnetic sensors. It can receive input signals from these sensors and convert them into digital key phase signals, which facilitates the coordination between the module and various detection components in the machinery monitoring system.

- Application Scenarios

- Power Generation Industry: Deployed in thermal, hydroelectric, and other power plants to monitor equipment such as steam turbines, generators, and coal millers. When abnormal vibrations or overheating occur in the equipment, the module triggers relay actions to activate emergency shutdown procedures or start standby auxiliary equipment, avoiding large-scale power outages caused by equipment failures.

- Oil and Gas Industry: Installed on offshore drilling rigs, long-distance pipeline compressors, and natural gas processing facilities. It controls the interlocking of key equipment and emergency depressurization valves in response to faults like bearing wear and rotor imbalance, ensuring safe operation in flammable and explosive hazardous environments.

- Chemical Industry: Applied to reaction kettles, transfer pumps, and agitators in chemical plants. It connects with temperature and pressure monitoring modules. When process parameters deviate from the set range, it promptly triggers relay actions to isolate faulty equipment or activate fire suppression systems, reducing the risks of chemical leaks and explosions.

- General Manufacturing Industry: Integrated into production lines to monitor large motors, gearboxes, and centrifugal pumps. It outputs control signals through relays when detecting equipment faults, such as abnormal vibrations, to stop related production processes in a timely manner, minimizing production losses caused by equipment damage.

- Railway Industry: Used to monitor the operating status of key rotating machinery in railway locomotive traction systems and power supply equipment. It triggers maintenance alarms or adjusts equipment operating parameters through relay actions when abnormalities are detected, ensuring the stable operation of railway transportation and reducing the probability of operational disruptions.

Reviews

There are no reviews yet.