Product Short Description

Bently 3500/20 125744 – 02 Detailed Information

- Product Name

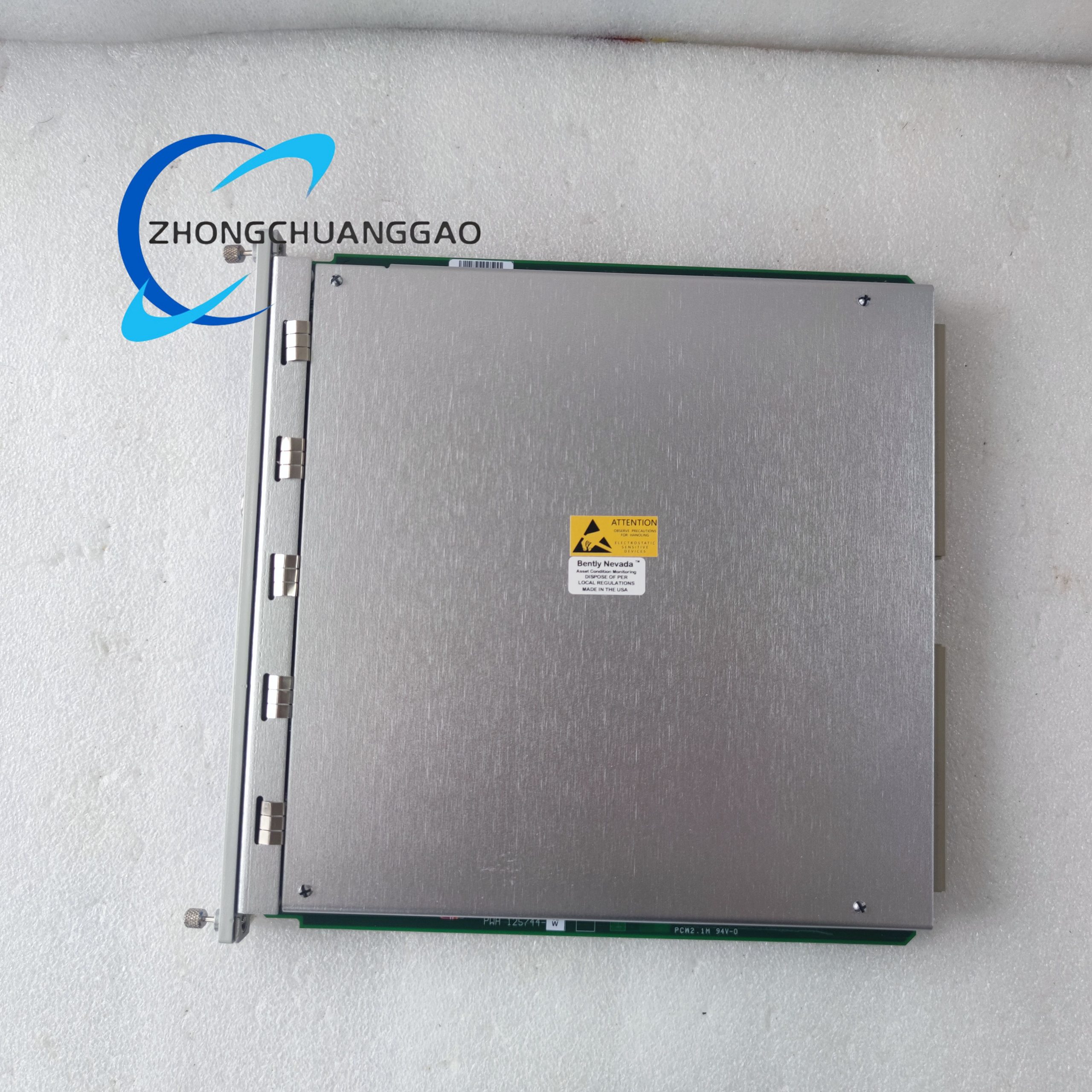

- Rack Interface Module (RIM) for Bently Nevada 3500 Series Machinery Monitoring and Protection System

- Product Introduction

This module is a core component of the Bently Nevada 3500 series monitoring and protection system and is currently produced under Schneider Electric after Bently Nevada was incorporated into it. It serves as a key connection hub between the 3500 series rack and external equipment. It must be installed in the No.1 slot of the rack adjacent to the power supply module to undertake the core tasks of rack configuration management, data transmission and communication with external systems. The module does not involve the direct collection and processing of key monitoring data such as mechanical vibration, so its operation status will not affect the normal monitoring path of the entire system. It is manufactured in the United States, supplied with original packaging and comes with a 12 – month factory warranty, which is a crucial supporting component for ensuring the stable operation of industrial machinery monitoring systems.

Description

- Technical Specifications

- Power – Related Parameters: The typical power consumption is fixed at 4.75 watts, and it adopts a 24V DC power supply. The rated value of its OK relay is 5A 24Vdc/120Vac, matching a 120 – watt/600VA switching power supply.

- Communication Performance: It supports RS – 232/RS – 422 serial communication and Ethernet communication. The maximum data transmission rate reaches 38.4 k baud. The effective transmission distance of RS – 232 cables can reach 30 meters, and that of RS – 422 cables can extend to 1200 meters.

- Physical Dimensions and Weight: It has a height of 9.5 inches, a width of 0.96 inches and a depth of 9.52 inches. The net weight of the module is about 0.91 kilograms, and the shipping weight is 2 kilograms, which is compatible with the installation space of the 3500 series standard rack.

- Environmental Adaptability: The operating temperature range is from – 30°C to + 65°C, and the storage temperature range is from – 40°C to + 85°C. It has an IP20 protection level, which can resist the intrusion of solid objects with a maximum size of 12 millimeters and adapt to dusty industrial environments.

- Other Core Specifications: It is designed with 4 input channels, the sampling rate is 1000 Hz, and the data resolution reaches 16 bits. The built – in 1GB storage capacity can temporarily store configuration information and communication logs.

- Function Features

- Dual – mode Configuration Support: It supports both local and remote configuration modes for the 3500 series rack. Maintenance personnel can directly connect to the module on – site for parameter setting, or conduct remote configuration and modification of rack parameters through the network, which is flexible for different application scenarios.

- Visual Status Diagnosis: The front panel is equipped with multiple LED indicator lights including TX/RX, CONFIG OK and OK relay. These indicators can intuitively display the communication status, configuration validity and rack operation status respectively, enabling technicians to quickly judge the module’s working condition without complex detection equipment.

- Configuration Password Protection: It is equipped with a dedicated password protection function. Only when the input password matches the preset password in the rack configuration software can the communication connection with the 3500 rack be established. This prevents unauthorized modification of rack parameters and ensures the security of the system configuration.

- Strong External Compatibility: It can seamlessly integrate with external communication processors of Bently Nevada such as TDXnet, TDIX and DDIX. It can also achieve data sharing and collaborative operation with DCS and SCADA systems, which is highly compatible with various industrial automation systems.

- Redundancy Support for High – Reliability Scenarios: The TMR version of this module can be applied to triple modular redundancy systems. It can compare the output data of three redundant monitors in real time. Once a deviation between monitoring data occurs, it can promptly send out prompts to significantly improve the fault tolerance and reliability of the system.

- Application Scenarios

- Oil and Gas Industry: It is widely used in on – shore oil fields and offshore platforms. It is matched with the 3500 series system to provide communication support for the monitoring equipment of compressors, pipeline transport pumps and gas processing machinery. It ensures the smooth transmission of equipment operation data in high – humidity and high – salt – fog environments.

- Power Generation Industry: It is installed in thermal power, hydropower and nuclear power plants. It is connected to the 3500 series protection systems of core equipment such as turbines and generators. It realizes the data interaction between the monitoring system and the plant’s DCS system, facilitating the centralized management and remote monitoring of power generation equipment.

- Petrochemical Industry: It is deployed in petrochemical production workshops. It cooperates with the 3500 series modules to monitor reaction kettles, material transport pumps and other equipment. It ensures the stable transmission of temperature, pressure and other monitoring data, laying a foundation for the safe operation of the production line.

- Heavy Machinery Manufacturing: It is integrated into the production lines of large – scale construction machinery and precision machine tools. It connects the 3500 series monitoring modules and the factory’s intelligent management system. It transmits the operation accuracy data of mechanical components in real time to ensure the stability of product processing quality.

- Redundant Monitoring Systems: In industries with high requirements for system reliability such as aerospace equipment manufacturing and high – speed rail maintenance, its TMR version is applied to triple modular redundancy monitoring systems. It uses real – time data comparison to avoid monitoring errors caused by single – module failures and ensures the continuous and reliable operation of key equipment.

Reviews

There are no reviews yet.