Product Short Description

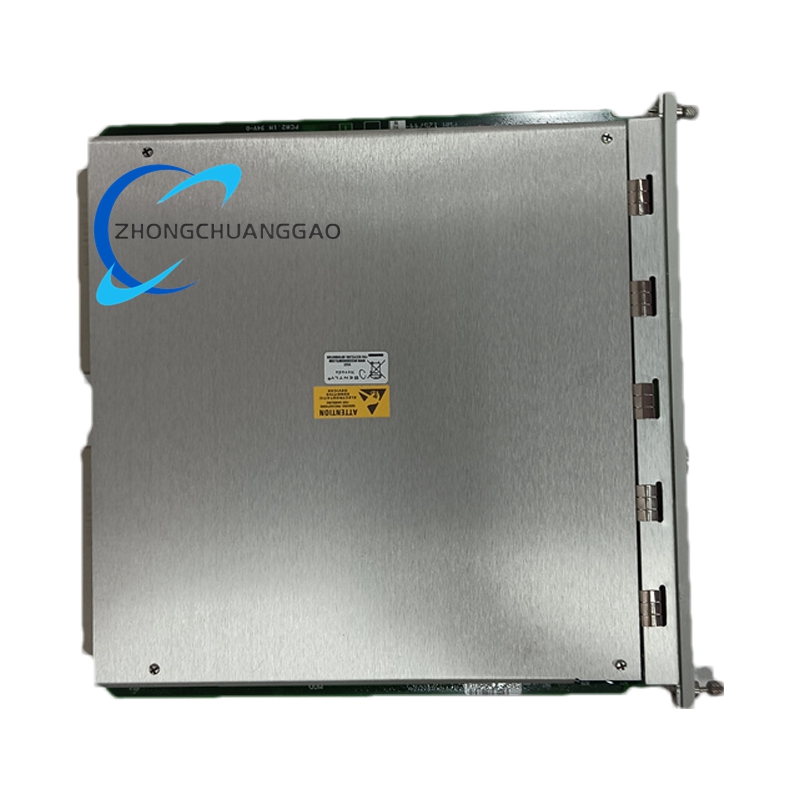

- Model: 3500/20

- Interface Types: RS-232, RS-422, Ethernet, Profibus, DeviceNet, Modbus RTU/TCP

- Communication Protocols: Supports Bently Nevada proprietary protocols (e.g., TDXnet, TDIX, DDIX) and standard industrial protocols (Modbus, Ethernet/IP, Profibus).

- Data Rate: Up to 38.4 kbps (serial); high-speed Ethernet options available.

- Power Supply: 24 V DC (standard); 120 V AC (optional for specific configurations).

- Operating Temperature: -30°C to 65°C (storage: -40°C to 85°C).

- Dimensions: Height 241.3 mm, width 24.4 mm, depth 99.1 mm.

- Weight: Approximately 0.45 kg.

- Protection Rating: IP20 (dust and particle resistance).

- Certifications: IEC 61131-3, CE, UL.

Description

Functional Features

- High-Speed Data Communication: Transmits real-time sensor data (vibration, temperature, pressure) to external systems via Ethernet or serial protocols.

- Redundancy Support: Configurable in dual-module redundancy to eliminate single points of failure, ensuring continuous operation in critical environments.

- Multi-Protocol Compatibility: Integrates with diverse control systems using Modbus, Profibus, Ethernet/IP, and Bently Nevada’s proprietary protocols.

- Real-Time Monitoring and Alerts: Continuously tracks equipment status and triggers instant alerts for abnormal conditions (e.g., vibration spikes, temperature overruns).

- Modular Design: Standard 19-inch rack-mountable for easy installation and scalability. Supports up to 32 connections per module.

- Advanced Diagnostics: Provides self-diagnostics, fault detection, and predictive maintenance insights to reduce downtime.

- Security: Password-protected configuration and read-only access to prevent unauthorized modifications.

- User-Friendly Interface: Intuitive LED indicators (OK, TX/RX, CONFIG OK) for quick status checks and troubleshooting.

Application Scenarios

- Oil and Gas: Monitors rotating equipment (pumps, compressors, turbines) to prevent failures and ensure safe operations.

- Power Generation: Tracks generator and motor health in thermal, hydro, and nuclear power plants.

- Chemical and Petrochemical: Controls critical parameters in continuous manufacturing processes (e.g., reactor temperature, pressure vessel integrity).

- Metallurgy: Oversees rolling mills, furnaces, and other high-stress equipment to optimize production efficiency.

- Water Treatment: Manages pump stations and filtration systems for reliable water supply.

- Pharmaceuticals: Ensures compliance with hygiene and safety standards in sterile production environments.

Key Advantages

- High Reliability: Built for harsh industrial conditions (vibration, dust, extreme temperatures).

- Flexible Integration: Supports multiple protocols and interfaces for seamless system expansion.

- Cost Efficiency: Reduces maintenance costs through predictive diagnostics and early fault detection.

- Global Trust: Deployed in over 80 countries, meeting stringent safety and performance standards.

- Scalability: Modular design allows easy addition of I/O modules for future needs.

- Longevity: Designed for 20+ years of continuous operation in demanding environments.

Reviews

There are no reviews yet.