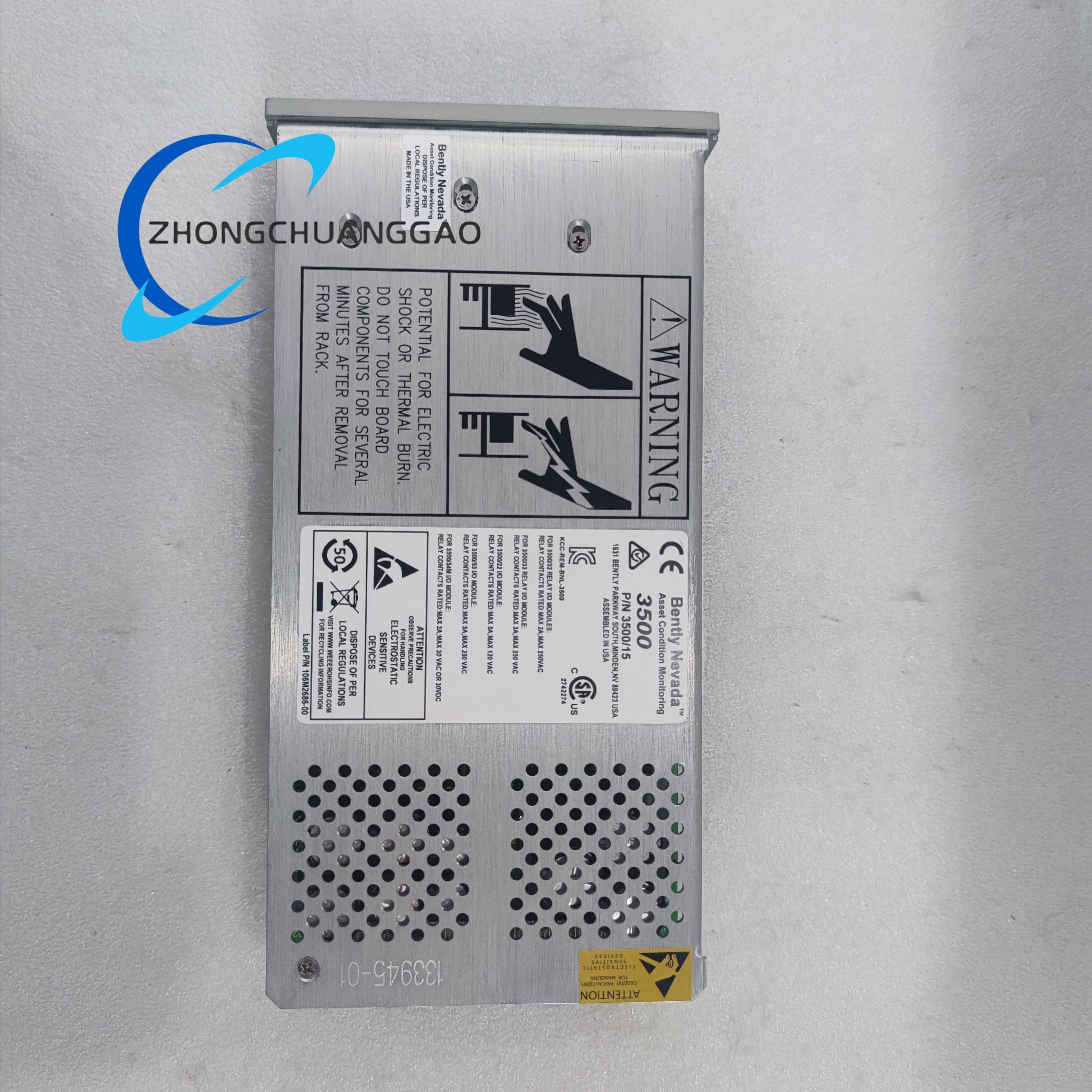

Product Short Description

Its part number structure, with “3500” denoting the foundational product series, “15133292” as the unique component identifier, and “01” indicating the standard configuration revision, signifies a design tailored for high-fidelity signal analysis and seamless data transmission. Unlike generic 3500 modules, this model combines advanced vibration signal conditioning (optimized for low-frequency and high-amplitude scenarios) with multi-protocol communication capabilities, serving as both a “signal refiner” and “data gateway” in complex monitoring systems. It is engineered to work seamlessly with Bently’s full range of 3300 series sensors, including 3300 XL proximity probes, 330850 velocity transducers, and 330851 acceleration sensors, while supporting compatible third-party devices. Adhering to stringent industrial standards (IEC 61326-1, UL 61010-1), the module features enhanced noise suppression, galvanic isolation, and a compact rack-mount form factor for 3500 chassis integration. By delivering precise vibration analytics and reliable data routing to upper-tier control systems, it enables early fault detection in assets where subtle vibration anomalies precede catastrophic failure—making it indispensable for industries such as power generation, oil & gas, petrochemical, and heavy manufacturing.

Description

Technical Specifications

-

Part Number: 350015133292-01

-

Module Type: Integrated vibration signal processing & communication module (single-channel primary, multi-protocol gateway)

-

Signal Processing Capability: Primary Parameter: Vibration (displacement, velocity, acceleration—simultaneous measurement)

-

Frequency Response: 0.05 Hz – 30,000 Hz (±1 dB); optimized for 0.05 Hz – 1,000 Hz (low-frequency shaft movement)

-

Signal Input Types: Eddy-current (proximity probe, 0–20 V DC), differential voltage (±10 V DC), piezoelectric charge (10–1000 pC/g)

-

Input Channels: 1 primary signal channel + 2 auxiliary monitoring channels

-

Signal Conditioning: Built-in charge amplifier (gain 10–1000 V/g), anti-aliasing filter (8th-order Butterworth), and DC offset correction

Measurement Ranges (Configurable): Displacement: 0–25 mm peak-to-peak (user-selectable 0–5/10/15/20 mm)

Velocity: 0–200 mm/s RMS (user-selectable 0–20/50/100/150 mm/s)

Acceleration: 0–300 g peak (user-selectable 0–50/100/200 g)

Communication Protocols: Ethernet: Modbus TCP/IP (10/100 Mbps), Ethernet/IP, and PROFINET (optional)

Serial: RS-485 (Modbus RTU), baud rate 9600–115200 bps, parity configurable

Diagnostic Interface: USB 2.0 (for local configuration and data logging)

Data Transmission Rate: Up to 1000 samples per second (SPS) for vibration data; 10 Hz for status updates

Output Configurations: Analog Outputs: 3 isolated 4–20 mA DC channels (1 per measurement parameter), 1000 Ω max load

Digital Outputs: 4 dry contacts (Form A), 2 A @ 250 V AC / 30 V DC (for alarms and fault signals)

Digital Status Indicators: 8 front-panel LEDs (power, signal lock, communication, faults per parameter)

Accuracy & Resolution: Displacement Accuracy: ±0.10% of full scale (at 25 °C ±5 °C)

Velocity Accuracy: ±0.15% of full scale (at 25 °C ±5 °C)

Acceleration Accuracy: ±0.10% of full scale (at 25 °C ±5 °C, 100 Hz reference)

Resolution: 24-bit ADC (signal input); 16-bit DAC (analog output)

Isolation & Protection: Channel Isolation: 2500 Vrms (channel-to-channel, channel-to-power)

Surge Protection: IEC 61000-4-5, ±2 kV (line to ground) for signal inputs

ESD Protection: IEC 61000-4-2, ±8 kV (contact), ±15 kV (air)

Noise Suppression: >80 dB common-mode rejection ratio (CMRR) at 50/60 Hz

Power Supply: Input Voltage: 24 V DC ±20% (nominal), galvanically isolated

Power Consumption: ≤ 5 W (full load, all outputs active)

Power Protection: Over-voltage (up to 36 V DC), under-voltage (≤18 V DC), reverse-polarity protection

Operating Environment: Temperature: -40 °C to +75 °C (-40 °F to +167 °F)

Humidity: 5%–95% RH (non-condensing), 40 °C dew point maximum

Altitude: Up to 3,000 meters (9,843 feet)

Shock & Vibration: IEC 60068-2-27 (shock: 50 g, 11 ms half-sine); IEC 60068-2-6 (vibration: 10 g, 10–2000 Hz)

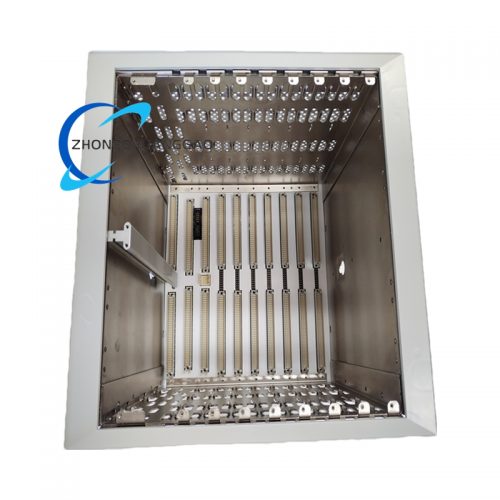

Mechanical Specifications: Housing: Anodized aluminum alloy, IP40 rating (when installed in 3500 chassis)

Mounting: 3500 system chassis (19-inch rack mount), 2 slot occupancy

Dimensions: 30.4 mm (width) x 152.4 mm (height) x 228.6 mm (depth)

Weight: 0.7 kg (1.54 lbs)

Certifications: UL 61010-1, CSA C22.2 No. 61010-1, CE (EN 61326-1), ATEX/IECEx (Zone 2/22, optional), IEC 61010-2-030

Function Features

-

Tri-Parameter Vibration Monitoring: Simultaneously measures displacement, velocity, and acceleration from a single sensor input, eliminating the need for multiple specialized modules. This is critical for assets like turbines, where shaft displacement (rotor alignment) and bearing acceleration (fatigue) must be monitored concurrently to assess overall health.

-

Low-Frequency Optimization: Extended frequency response down to 0.05 Hz ensures accurate measurement of slow-speed shaft movement—common in large gearboxes, SAG mills, and reciprocating compressors. The 8th-order Butterworth filter eliminates low-frequency noise, capturing subtle vibration patterns that precede mechanical failure.

-

Integrated Charge Amplifier: Built-in, gain-adjustable charge amplifier enables direct connection to piezoelectric acceleration sensors, removing the need for external signal conditioning. This reduces wiring complexity, minimizes signal loss, and lowers system costs compared to modular setups.

-

Multi-Protocol Communication: Supports Modbus TCP/IP, Ethernet/IP, and optional PROFINET, enabling seamless integration with diverse DCS/SCADA systems (e.g., Siemens PCS 7, Rockwell Allen-Bradley, Honeywell Experion). The RS-485 port provides local connectivity to 3500 core modules, ensuring redundant data paths.

-

High-Fidelity Signal Processing: 24-bit ADC delivers exceptional resolution for low-amplitude vibration signals (e.g., early-stage bearing wear), while >80 dB CMRR suppresses electrical noise from variable-frequency drives and power cables. This ensures the module transmits only actionable, accurate data.

-

Auxiliary Monitoring Channels: Two auxiliary channels support connection to temperature or pressure sensors, enabling correlated analysis (e.g., “vibration vs. bearing temperature”). This provides a holistic view of asset health, avoiding false alarms caused by isolated parameter spikes.

-

Configurable Alarm Logic: Four dry contacts and software-programmable thresholds allow users to define custom alarm triggers (e.g., “alert if displacement >10 mm AND temperature >80 °C”). Alarms are transmitted via both digital outputs and communication protocols, facilitating rapid response.

-

Local Data Logging: USB 2.0 interface supports on-site data logging (up to 16 GB via external flash drive), capturing vibration trends during transient events (e.g., startup/shutdown) for post-analysis. This is invaluable for troubleshooting intermittent faults that may not trigger real-time alarms.

-

Seamless 3500 Integration: Designed as a native 3500 component, it slots into 3500 chassis and integrates with 3500 display modules, alarm solvers, and other I/O modules. Configuration is centralized via Bently 3500 Software, ensuring consistent system-wide parameters.

-

Extreme Durability: Wide temperature range (-40 °C to +75 °C) and robust shock/vibration resistance enable operation in harsh environments—from arctic oil fields and desert power plants to high-vibration mining equipment. Optional ATEX/IECEx certification extends use to explosive areas.

Application Scenarios

-

Power Generation (Hydroelectric Turbines): Installed in hydroelectric plants to monitor slow-speed turbine runners and generator bearings. The module’s low-frequency response (0.05 Hz) captures shaft displacement caused by hydraulic imbalance, while auxiliary channels monitor bearing temperature. Modbus TCP/IP sends data to the plant’s DCS, with alarms triggering maintenance before runner damage occurs.

-

Oil & Gas (Reciprocating Compressors): Deployed in onshore refineries to monitor reciprocating compressors—prone to low-frequency vibration from piston movement. The module connects to 330851 acceleration sensors (rod load vibration) and 3300 XL probes (crankshaft displacement), with auxiliary channels tracking discharge pressure. Ethernet/IP integrates with the refinery’s Honeywell DCS, enabling correlated analysis of vibration and pressure.

-

Petrochemical (Large Gearboxes): Used in ethylene plants to monitor gearboxes driving centrifugal compressors. The module’s 24-bit resolution detects gear tooth wear via subtle acceleration changes, while displacement measurement tracks shaft misalignment. Custom alarm logic triggers a warning if both parameters exceed thresholds, avoiding unplanned shutdowns.

-

Mining (SAG Mills): Installed in copper and gold mines to monitor SAG mill pinion shafts and motor bearings. The module’s 10 g vibration resistance withstands mill-induced shocks, while low-frequency optimization captures shaft displacement from gear misalignment. RS-485 connects to local 3500 display panels, with USB logging capturing vibration during mill startup for post-analysis.

-

Marine (Ship Propulsion Systems): Deployed in large cargo ships to monitor slow-speed diesel engines and reduction gears. The module’s wide temperature range withstands engine room heat, while dual-parameter monitoring (displacement + acceleration) detects crankshaft wear and bearing fatigue. Digital outputs trigger engine alarms if thresholds are exceeded, preventing catastrophic failure at sea.

-

Steel Manufacturing (Cold Rolling Mills): Used in steel mills to monitor rolling mill backup rolls and drive gearboxes. The module’s noise suppression (>80 dB CMRR) resists interference from electric motors, while acceleration measurement detects roll bearing fatigue. PROFINET integrates with the mill’s Siemens PCS 7, enabling real-time adjustment of roll pressure to reduce vibration.

-

Offshore Oil (Subsea Pump Stations): Deployed on offshore platforms (ATEX Zone 2) to monitor subsea pump vibration and pressure. The module connects to subsea 330851 sensors (vibration) and pressure transmitters (auxiliary channel), with Modbus TCP/IP sending data to onshore SCADA. Surge protection safeguards against electrical transients from platform power systems.

-

Aerospace (Ground Test Rigs): Installed in aircraft engine test facilities to monitor turbine vibration during ground testing. The module’s high resolution captures low-amplitude blade vibration, while USB logging records data during startup/shutdown cycles. Ethernet/IP transmits data to test cell data acquisition systems, supporting engine certification.

-

Chemical Processing (Mixing Vessels): Used in pharmaceutical and chemical plants to monitor large mixing vessel agitators. The module connects to 3300 XL probes (agitator shaft displacement) and 330850 velocity sensors (bearing vibration), with auxiliary channels tracking vessel temperature. Alarms integrate with the plant’s SCADA, ensuring product quality by preventing agitator failure during batch processing.

-

Renewable Energy (Wind Turbine Gearboxes): Deployed in wind farms to monitor wind turbine gearboxes. The module’s low-frequency response captures gear meshing vibration, while auxiliary channels track oil temperature. Data is transmitted via Ethernet/IP to the wind farm’s SCADA system, enabling predictive maintenance scheduling and reducing downtime by 35%.

Reviews

There are no reviews yet.