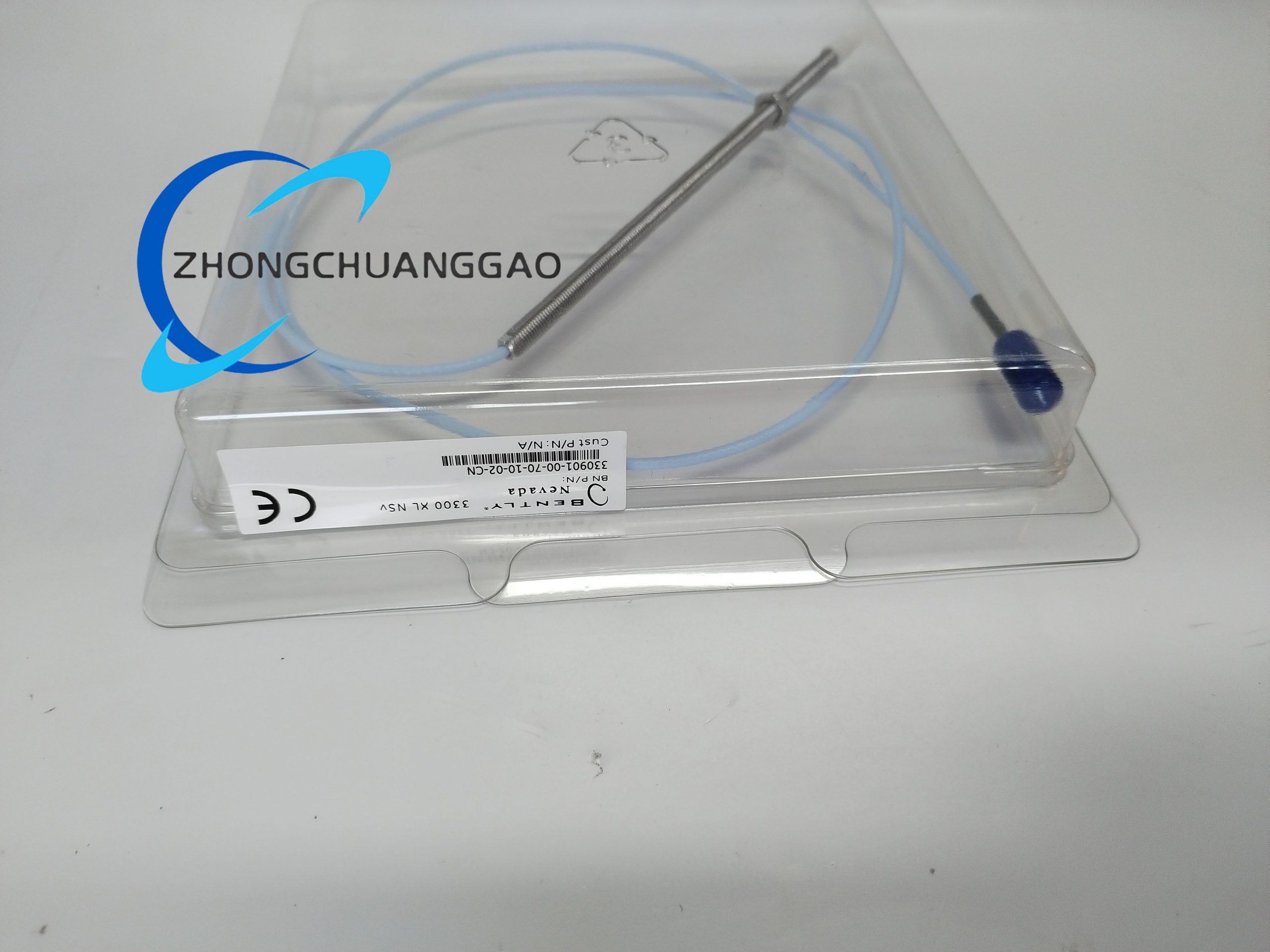

Product Short Description

The Bently 330901-00-70-10-02-CN is a specialized dual-axis vibration transmitter tailored for the Chinese industrial market (denoted by the “CN” suffix), belonging to Bently Nevada’s globally acclaimed 3300 XL condition monitoring series. This device integrates advanced piezoelectric sensing and signal processing technologies to simultaneously measure vibration in two orthogonal axes (X and Y), delivering comprehensive insights into the health of rotating machinery. The part number’s numerical sequence decodes key configurations: “70” indicates a 70 mm/s RMS vibration velocity range, “10” specifies 10-32 UNF mounting threads, and “02” denotes dual-channel output capabilities. Engineered to comply with Chinese industrial standards (GB/T 13926 series) and electromagnetic compatibility (EMC) regulations (GB/T 17626), the transmitter features a compact DIN-rail mountable design, robust anti-interference performance, and seamless compatibility with local control systems. It converts raw vibration signals into industry-standard 4-20 mA outputs, enabling direct integration with Bently 3300 XL monitoring racks and third-party DCS/SCADA platforms widely used in China’s power, petrochemical, and manufacturing sectors. By providing real-time, dual-axis vibration data, the transmitter facilitates early detection of equipment anomalies such as misalignment, bearing wear, and rotor imbalance, minimizing unplanned downtime and supporting predictive maintenance strategies critical for China’s industrial upgrading initiatives.

Description

Technical Specifications

-

Part Number: 330901-00-70-10-02-CN

-

Device Type: Dual-axis (X/Y) vibration velocity transmitter

-

Measurement Parameter: Vibration velocity (RMS); optional acceleration (g) and displacement (mm) via signal conversion

-

Measurement Range: 0-70 mm/s RMS (per axis)

-

Frequency Response: 2 Hz – 1,000 Hz (±3 dB) for both axes

-

Sensitivity: 100 mV/(mm/s) RMS (calibrated at 159 Hz)

-

Output Configuration: Dual 4-20 mA DC channels (one per axis); 2-wire/4-wire selectable

-

Supply Voltage: 18-32 V DC (nominal 24 V DC) – compliant with Chinese industrial power systems

-

Power Consumption: ≤ 5 W (4-wire mode); ≤ 3 W (2-wire mode)

-

Operating Temperature Range: -20 °C to +70 °C (-4 °F to +158 °F) – adapted to China’s diverse climatic conditions

-

Storage Temperature Range: -40 °C to +85 °C (-40 °F to +185 °F)

-

Mechanical Construction: Housing: Flame-retardant polycarbonate (UL 94 V-0; compliant with GB 8624-2012 B1 grade)

-

Mounting: 35 mm DIN rail or 10-32 UNF threaded stud

-

Termination: Screw terminals (accept 12-24 AWG wire; compatible with Chinese standard cables)

Accuracy: ±0.5% of full-scale output

EMC Compliance: GB/T 17626.2 (ESD), GB/T 17626.3 (radiated immunity), GB/T 17626.6 (conducted immunity)

Ingress Protection Rating: IP40 (housing); IP20 (front panel) – suitable for control cabinet environments

Fault Diagnostics: Dual Form C fault relays (2 A @ 250 V AC/30 V DC) for signal loss, overrange, or power failure

Weight: 350 grams (0.77 pounds) (DIN rail configuration)

Certifications: CE; CCC (China Compulsory Certification) for electrical safety

Function Features

-

Dual-Axis Simultaneous Measurement: Captures vibration data in X and Y axes simultaneously, providing a 360° view of machinery health. This eliminates blind spots in monitoring, critical for detecting complex faults like rotor misalignment and shaft bending common in large Chinese industrial pumps and turbines.

-

Chinese Market Compliance: Meets CCC certification requirements and GB series standards, ensuring seamless integration into Chinese industrial networks without additional modifications. The EMC design resists interference from high-voltage power grids prevalent in China’s manufacturing hubs.

-

Industry-Standard 4-20 mA Output: Dual 4-20 mA channels deliver calibrated data compatible with mainstream Chinese DCS systems (e.g., Sinopec’s SUPCON JX-300X, Huawei’s eLTE Industrial Internet platform). The 4 mA “live zero” design distinguishes between normal operation and power failure, preventing false alarms.

-

Flexible Mounting Options: Supports both DIN rail installation (common in Chinese control cabinets) and 10-32 UNF threaded mounting for direct attachment to machinery. Screw terminals accommodate local cable standards, simplifying on-site wiring.

-

Proactive Fault Monitoring: Dual fault relays trigger independent alerts for each axis, enabling targeted troubleshooting of issues such as sensor signal loss or excessive vibration. This aligns with China’s “Smart Factory” initiatives by supporting predictive maintenance workflows.

-

Wide Voltage Tolerance: The 18-32 V DC supply range accommodates fluctuations in Chinese industrial power systems, ensuring stable performance in remote areas or facilities with inconsistent voltage.

-

Flame-Retardant Design: Complies with GB 8624-2012 B1 grade flame resistance, making it suitable for hazardous environments in China’s petrochemical and coal-fired power plants.

-

Seamless System Integration: Interfaces directly with Bently 3300 XL monitoring systems and Chinese-made SCADA platforms (e.g., Kingview, Intouch). Optional Modbus RTU communication (via RS485) supports integration into industrial internet of things (IIoT) networks.

-

Temperature Adaptability: Operates reliably across China’s diverse climates, from cold northern industrial zones (-20 °C) to hot southern manufacturing facilities (+70 °C), ensuring consistent performance year-round.

Application Scenarios

-

Coal-Fired Power Plants (China’s Dominant Power Source): Installed in boiler feedwater pumps, induced draft fans, and turbine generators. Dual-axis monitoring detects bearing wear and rotor imbalance, critical for ensuring continuous operation of coal-fired units that supply over 50% of China’s electricity.

-

Petrochemical Industry (China’s Strategic Sector): Deployed in refineries (e.g., Sinopec, PetroChina) for catalytic cracker fans, centrifugal compressors, and pipeline pumps. CCC certification and flame-retardant design comply with safety regulations for handling flammable hydrocarbons.

-

Iron & Steel Manufacturing (China’s Heavy Industry): Used in rolling mill motors, blast furnace blowers, and continuous casting machines. Dual-axis data identifies misalignment in high-load equipment, supporting China’s steel industry’s drive for energy efficiency and reduced downtime.

-

Renewable Energy (China’s Green Transition): Installed in wind turbine gearboxes and solar tracker drives. The transmitter’s wide temperature range adapts to China’s wind farms in Inner Mongolia (cold) and solar plants in Xinjiang (hot), supporting the country’s carbon neutrality goals.

-

Water & Wastewater Treatment (China’s Infrastructure Upgrade): Deployed in large pumps at municipal wastewater plants (e.g., in Beijing, Shanghai). Dual-axis monitoring ensures reliable operation of equipment critical to China’s urban water management initiatives.

-

Automotive Manufacturing (China’s Largest Global Market): Used in production lines for stamping presses, robotic welders, and conveyor systems. The transmitter’s compact design fits in dense control cabinets, supporting the efficiency of China’s automotive factories.

-

Chemical & Pharmaceutical (China’s High-Tech Sector): Installed in reactor agitators and centrifuges at facilities compliant with China’s GMP standards. The flame-retardant housing and fault monitoring ensure safety in chemical processing.

-

Mining (China’s Resource Sector): Deployed in coal mine conveyor motors and ore crushers. The robust design withstands dust and vibration in China’s mining regions, ensuring reliable operation of equipment critical to resource supply.

Reviews

There are no reviews yet.