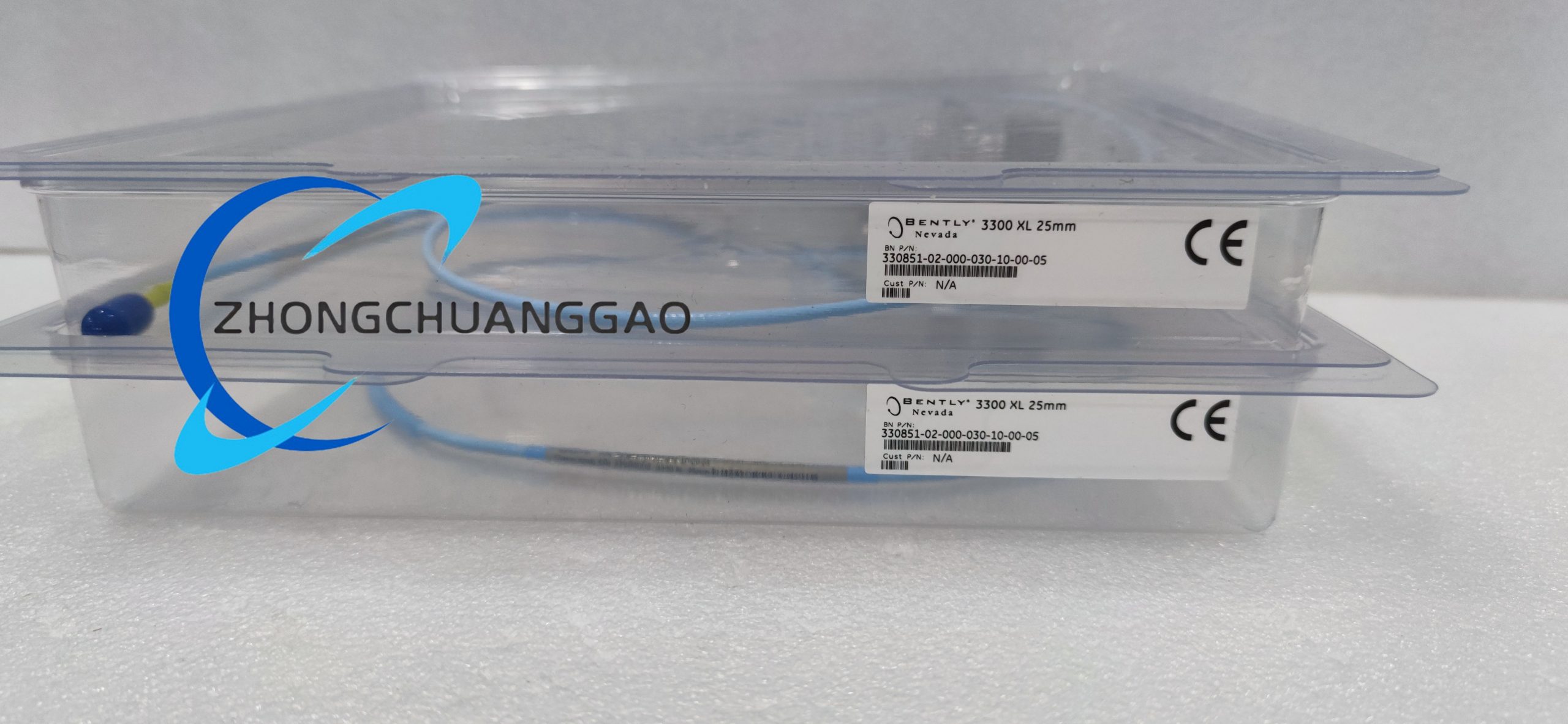

Product Short Description

Product Introduction

The Bently 330851-02-000-030-10-00-05 is a specialized acceleration transducer within Bently Nevada’s renowned 3300 XL product line, engineered for high-precision condition monitoring of industrial machinery. This device leverages advanced piezoelectric technology to convert mechanical acceleration (a key indicator of equipment health) into stable electrical signals, enabling accurate measurement of dynamic forces and vibration in rotating, reciprocating, and linear equipment. The long alphanumeric part number denotes its custom configuration: a standard 330851 base model with a 30-meter (98.4 feet) shielded cable, 10-32 UNF mounting threads, and optimized signal conditioning for industrial environments. Unlike velocity or proximity transducers, it excels at capturing high-frequency vibration components—critical for early detection of bearing fatigue, gear tooth wear, and structural resonance. Manufactured to meet strict industrial standards, the transducer features a rugged housing, weather-resistant cable, and compatibility with Bently Nevada’s 3300 XL monitoring systems and third-party control platforms. It delivers real-time, actionable data that empowers maintenance teams to implement predictive strategies, reduce unplanned downtime, and protect high-value assets across sectors where equipment reliability directly impacts productivity and safety.

Description

Technical Specifications

-

Part Number: 330851-02-000-030-10-00-05

-

Technology Type: Piezoelectric acceleration transducer (charge-mode with internal signal conditioning)

-

Measurement Parameter: Vibration acceleration (peak and RMS); convertible to velocity and displacement via signal processing

-

Measurement Range: ±50 g peak (g = 9.81 m/s²)

-

Frequency Response: 0.5 Hz to 10,000 Hz (±3 dB)

-

Sensitivity: 100 mV/g (calibrated at 159 Hz)

-

Output Signal: 4–20 mA DC (proportional to acceleration); optional 0–5 V DC output

-

Supply Voltage: 18–32 V DC (nominal 24 V DC)

-

Power Consumption: ≤ 3 W at 24 V DC

-

Cable Configuration: 30 meters (98.4 feet) shielded twisted pair; FEP insulation, stainless steel armor

-

Mounting Configuration: 10-32 UNF threaded stud (integral to transducer housing)

-

Operating Temperature Range: -40 °C to +125 °C (-40 °F to +257 °F)

-

Storage Temperature Range: -55 °C to +150 °C (-67 °F to +302 °F)

-

Mechanical Construction: Housing: Titanium alloy (lightweight, corrosion-resistant)

-

Sensing Element: Lead zirconate titanate (PZT) piezoelectric crystal

-

Cable Shielding: 95% coverage braided tinned copper (EMI/RFI protection)

Accuracy: ±1% of full-scale measurement (across 1–10,000 Hz)

Resolution: 0.001 g peak

Ingress Protection Rating: IP67 (dust-tight, protected against temporary submersion)

Connector Type: Bently Nevada proprietary 6-pin bayonet connector (pre-terminated on cable)

Shock Resistance: 2,000 g peak (1 ms duration, half-sine wave)

Weight: 350 grams (0.77 pounds) without cable; 1.8 kg (3.97 pounds) with 30-meter cable

Function Features

-

High-Frequency Measurement Capability: The 0.5–10,000 Hz frequency range excels at capturing high-frequency vibration components (500–10,000 Hz) that indicate early-stage bearing wear, gear tooth pitting, and electrical faults in motors—signals often missed by lower-frequency transducers.

-

Extended Cable for Remote Installation: The 30-meter armored cable enables remote mounting of the transducer on hard-to-reach equipment (e.g., tall turbines, overhead conveyors) while maintaining signal integrity. The stainless steel armor resists physical damage, while FEP insulation withstands chemicals and extreme temperatures.

-

Precision 10-32 UNF Mounting: The 10-32 UNF threaded stud ensures secure, repeatable mounting, minimizing measurement error caused by loose connections. It is compatible with standard mounting brackets and adapters, simplifying installation on diverse machinery surfaces.

-

Titanium Housing for Extreme Environments: The titanium alloy housing combines lightweight design with exceptional corrosion resistance, making it suitable for offshore, marine, and chemical processing environments. It withstands exposure to saltwater, acids, and industrial solvents without degradation.

-

Stable Signal Output: Internal signal conditioning converts high-impedance charge signals from the PZT crystal to a low-impedance 4–20 mA DC output, reducing noise and signal loss over long cable runs. The balanced design rejects electromagnetic interference (EMI) from nearby power cables and motors.

-

Multi-Parameter Compatibility: Acceleration data can be mathematically converted to velocity (mm/s) or displacement (mm) via Bently Nevada monitoring systems or third-party software, eliminating the need for multiple transducers and simplifying system integration.

-

Exceptional Shock Resistance: Withstands 2,000 g peak shock, making it durable for high-impact applications such as reciprocating engines, mining crushers, and construction equipment. The robust design prevents damage from transient mechanical stress.

-

Seamless System Integration: The proprietary bayonet connector mates directly with Bently 3300 XL monitoring racks, transmitters, and data acquisition units. It also integrates with DCS, SCADA, and predictive maintenance platforms (e.g., OSIsoft PI, IBM Maximo) via standard analog outputs.

-

Low Drift Performance: The PZT crystal and precision electronics deliver minimal temperature-induced drift, ensuring consistent 100 mV/g sensitivity across the entire operating temperature range. This eliminates false alarms and ensures reliable long-term monitoring.

Application Scenarios

-

Power Generation (Turbines & Generators): Installed on gas turbines, steam turbines, and generator bearings in thermal and nuclear power plants. It captures high-frequency vibration from turbine blades and generator windings, enabling early detection of imbalance, misalignment, or electrical faults.

-

Aerospace & Defense (Engine Testing): Used in jet engine test stands and aircraft auxiliary power units (APUs). The high-frequency response and shock resistance monitor engine components during rigorous testing, ensuring compliance with aerospace safety standards.

-

Oil & Gas (Offshore & Refining): Deployed on offshore drilling rigs, subsea pumps, and refinery catalytic crackers. The titanium housing resists saltwater corrosion, while the 30-meter cable accommodates remote mounting on large equipment.

-

Mining & Minerals Processing: Applied to crushers, grinding mills, and conveyor system motors. The shock resistance and armored cable withstand high-impact, high-dust environments, monitoring vibration to prevent equipment failure in continuous-production operations.

-

Automotive Manufacturing (Engine & Transmission Testing): Used in engine dynamometers and transmission test rigs. The high precision and wide frequency range capture vibration from rotating components, ensuring product quality during manufacturing.

-

Marine & Naval Systems: Installed in ship propulsion engines, propeller shafts, and marine generators. The corrosion-resistant design and IP67 rating withstand saltwater exposure, while the 10-32 UNF mounting simplifies installation on metal surfaces.

-

Chemical & Pharmaceutical (High-Speed Mixers): Monitors high-speed mixers, centrifuges, and agitators in chemical reactors. The FEP cable insulation resists exposure to solvents and chemicals, complying with strict safety and hygiene standards.

-

Renewable Energy (Wind Turbines): Deployed on wind turbine gearboxes and generators. The 30-meter cable enables mounting on nacelle components, while the high-frequency response detects gear wear and bearing degradation in remote wind farm locations.

Reviews

There are no reviews yet.