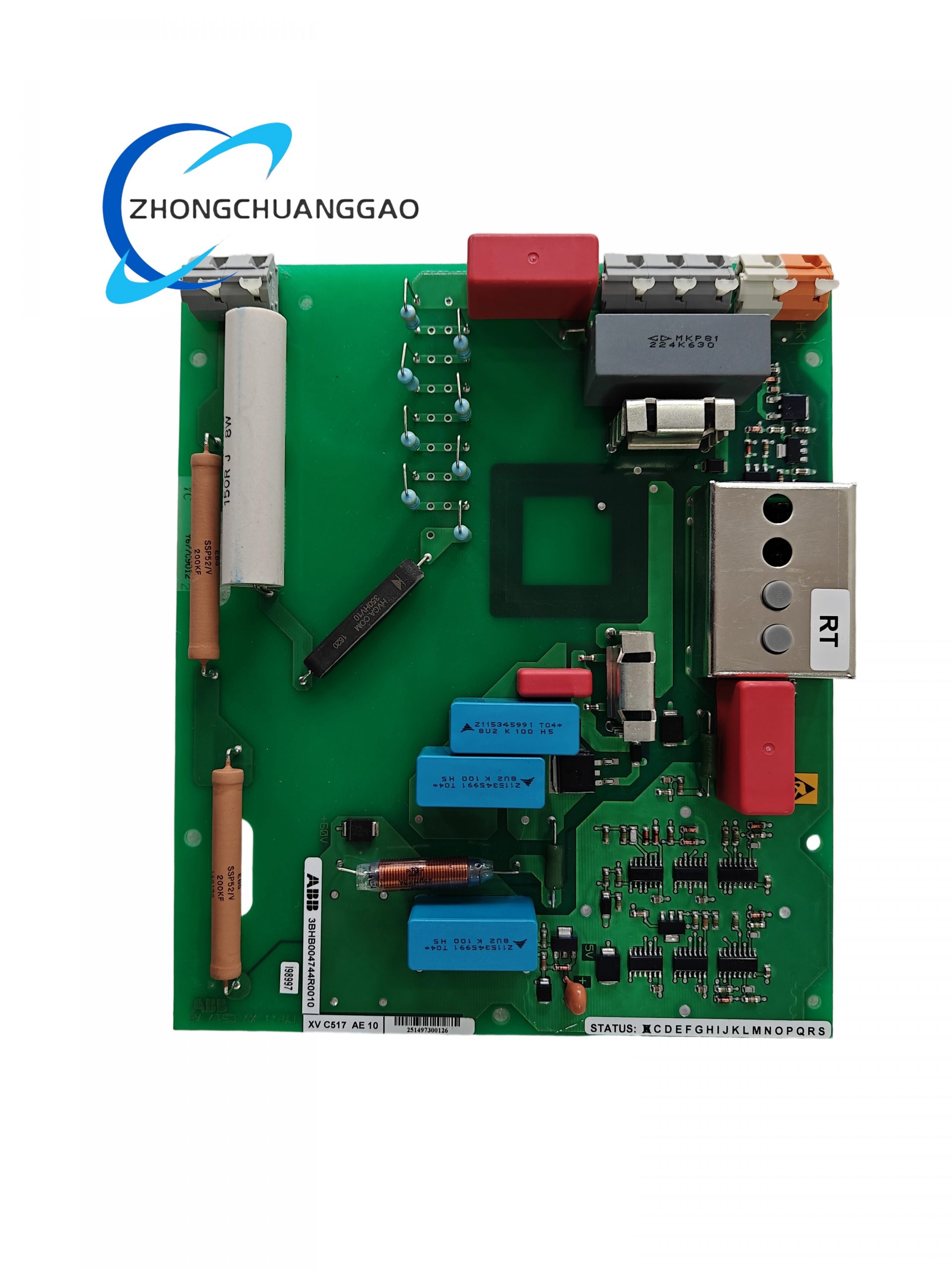

Product Short Description

Technical Specifications

- Product Type: Digital Input/Output Module (8DI/8DO)

- Input Channels: 8 – way digital input (dry – contact or wet – contact selectable)

- Output Channels: 8 – way digital output (relay contacts)

- Contact Type: Normally Open (NO) or Normally Closed (NC) selectable

- Rated Load Current: 5A (resistive load)/3A (inductive load)

- Input Voltage Range: DC 24V±20% (with reverse – polarity protection)

- Communication Protocols: Modbus RTU, Modbus TCP/IP, Profibus DP

- Isolation Method: Opto – isolation (between channels and between the field side and the system side)

- Diagnostic Functions: Channel status monitoring, over – current protection, power – failure alarm

Description

- Physical Dimensions: 120mm×80mm×50mm

- Weight: 300g

- Protection Level: IP67 (enclosure)

- Installation Method: DIN – rail mounting or wall – mounting

- Operating Temperature: – 40°C to + 70°C

- Storage Temperature: – 40°C to + 85°C

Function Features

- High Reliability and Harsh Environment Adaptability: It adopts redundant power supply design and industrial – grade relays, which can withstand high – humidity (95% RH non – condensing), strong electromagnetic interference (EN 61000 – 6 – 2) and mechanical vibration (IEC 60068 – 2 – 6) environments. Its impact resistance reaches 10g (11ms), suitable for harsh working conditions such as ships and mines. The built – in over – current protection mechanism can quickly cut off the output when the load is abnormal to avoid equipment damage.

- Flexible Configuration and Expansion Capability: The 8 – way input channels support dry – contact/wet – contact mode switching, and the output channels can be independently configured as normally open or normally closed contacts to meet different control logic requirements. Through the Modbus protocol, users can remotely monitor the status of each channel and adjust parameters, significantly reducing the system debugging cost. In addition, the module supports hot – swapping, allowing the replacement of faulty modules during system operation, greatly reducing downtime.

- Wide Compatibility and Intelligent Operation and Maintenance: The module is compatible with ABB Advant OCS, Freelance and third – party PLC/DCS systems, and can be directly connected to the main controller through the I/O BUS, simplifying the system wiring complexity. The built – in data logger can store historical operation logs. Combined with the ABB CMT 1000 debugging tool, users can perform trend analysis and predictive maintenance to identify potential faults in advance.

- Compliance and Energy Efficiency Optimization: The ABB XVC517AE10 3BHB004744R0010 is certified by UL and CE, and complies with the IEC 61508 SIL2 standard, suitable for industrial scenarios with high safety level requirements. Its low – power design (typical power consumption ≤5W) can reduce energy consumption. Combined with a wide voltage input range, it further improves the system economy.

Application Scenarios

- Industrial Automation Production Lines: In production lines such as automotive manufacturing and electronic assembly, the ABB XVC517AE10 is used to control the clamping of robotic arms, the start – stop of conveyor belts and the signal triggering of detection equipment. For example, through the Modbus protocol 联动 with the PLC, synchronous control of multiple devices is achieved to improve the production cycle efficiency.

- Process Control and Energy Management: In chemical reaction kettles and sewage treatment systems, the module can drive actuators such as electric valves and aeration blowers, and realize closed – loop control combined with sensor feedback. Its wide voltage adaptability can be compatible with different national power standards, suitable for cross – border projects.

- Power and Infrastructure: In smart grids, the ABB XVC517AE10 is used for substation switch status monitoring and standby power supply switching control. Its IP67 protection level allows it to be directly installed in outdoor distribution boxes, reducing the space occupation of the control cabinet.

- Building Automation: In commercial buildings, the module can control lighting systems, HVAC equipment and security access control, and is integrated with the building management system (BMS) through the Modbus TCP/IP protocol to achieve energy consumption optimization and remote monitoring.

Be the first to review “ABB XVC517AE10 3BHB004744R0010 Control Module” Cancel reply

Reviews

There are no reviews yet.