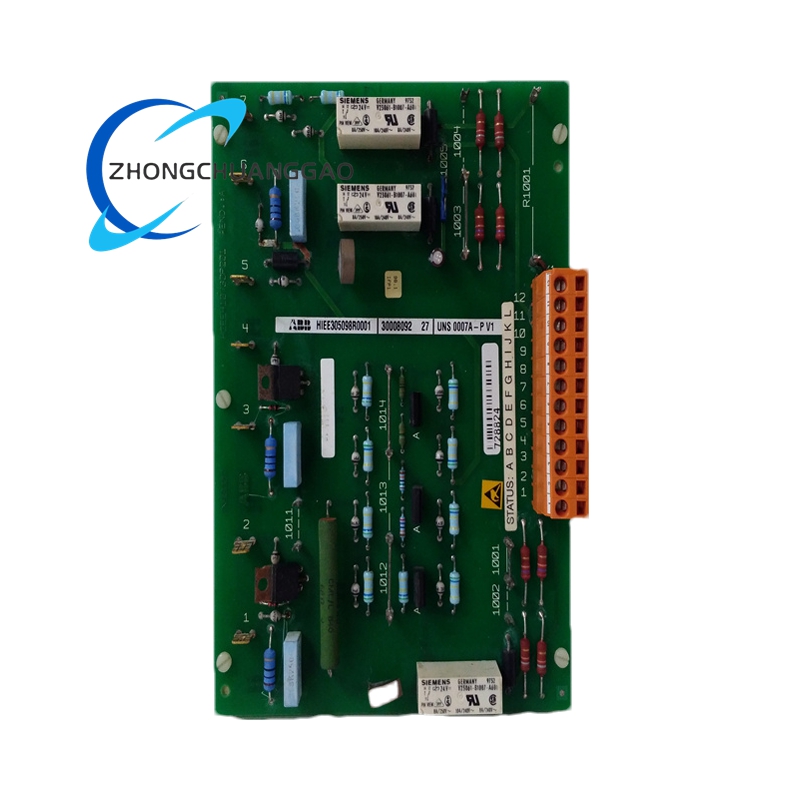

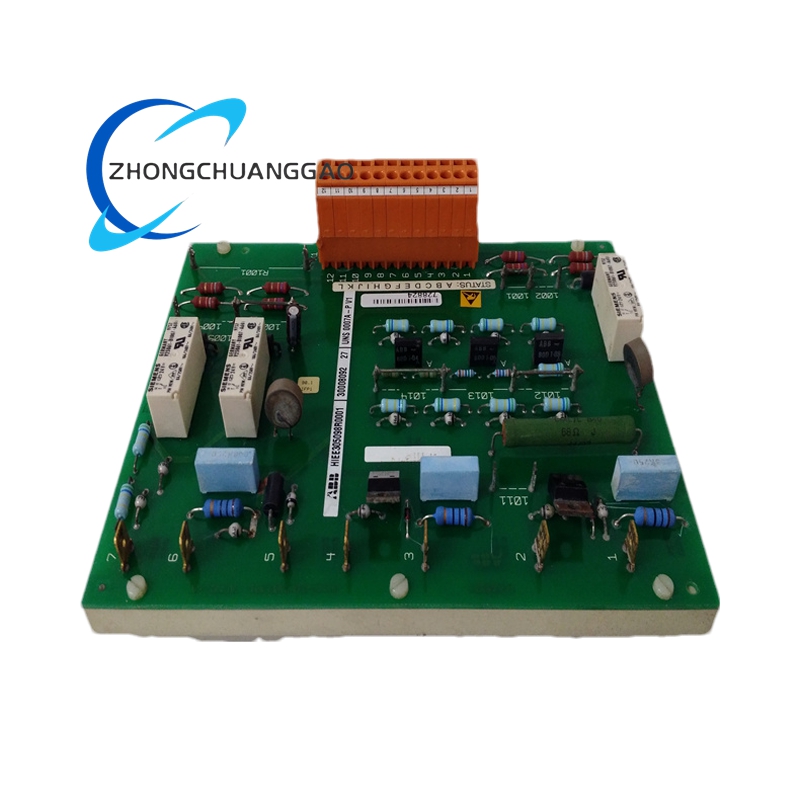

Product Short Description

Technical Specifications

- Communication Protocols:

- Supports PROFIBUS DP, CANopen, Modbus RTU, and Ethernet/IP (depending on configuration).

- Enables seamless integration with ABB and third-party control systems.

- Power Supply:

- 24 VDC nominal input.

- Low power consumption (typically <10 W).

- Environmental Resistance:

- Operating Temperature: -20°C to +60°C (-4°F to +140°F).

- Humidity: Up to 95% non-condensing.

- IP Rating: IP20 (dust-resistant, indoor use).

Description

- Mechanical Design:

- DIN rail mounting for easy installation.

- Robust casing for industrial environments.

- Input/Output (I/O) Capacity:

- Configurable digital and analog channels (specific configuration depends on firmware version).

- Supports up to 32 digital inputs/outputs (DI/DO) and 8 analog inputs/outputs (AI/AO) in modular setups.

- Diagnostic Capabilities:

- Built-in self-testing and fault detection.

- Real-time status monitoring via LED indicators and network protocols.

Key Features

- Multi-Protocol Support: Enables integration with diverse fieldbus networks without hardware modifications.

- High-Speed Communication: Up to 12 Mbps data transfer rate for real-time control.

- Flexible I/O Configuration: Digital and analog channels can be tailored for alarm management, event triggering, and timing sequences.

- Redundancy Support: Enhances system reliability through redundant communication paths and I/O configurations.

- Signal Isolation: Protects against electrical noise and ground loops.

- Easy Configuration: Software-based setup for protocol selection, I/O mapping, and diagnostic settings.

- Firmware Upgradability: Supports remote updates to add new protocols or features.

Functional Capabilities

- Field Device Integration: Connects sensors, actuators, and other field devices to control systems.

- Protocol Conversion: Switches between supported protocols (e.g., PROFIBUS to Ethernet/IP) via software settings.

- Data Aggregation: Collects and processes data from multiple field devices for centralized control.

- System Monitoring: Provides real-time diagnostics and alerts for proactive maintenance.

- Redundant Operation: Maintains communication during primary path failures.

Application Scenarios

- Power Generation:

- Monitoring and control of generators, transformers, and switchgear in thermal, hydro, and nuclear power plants.

- Renewable Energy:

- Wind turbine pitch control, solar inverter monitoring, and battery energy storage system (BESS) management.

- Manufacturing:

- Automation of production lines, packaging machinery, and material handling systems.

- Transportation:

- Elevator control, electric vehicle (EV) charging infrastructure, and railway signaling.

- Building Automation:

- HVAC control, lighting management, and access control in commercial facilities.

- Water and Wastewater:

- Pump station control, water treatment, and distribution network monitoring.

Advantages

- Cost Efficiency: Reduces wiring complexity and maintenance costs through centralized fieldbus integration.

- Scalability: Supports modular expansion for large-scale automation projects.

- Interoperability: Compatible with ABB 800xA DCS, AC 800M controllers, and third-party systems via open protocols.

- Future-Proof Design: Firmware updates enable protocol expansions (e.g., adding OPC UA support).

- Safety Compliance: Meets IEC 61131-3, CENELEC, and SIL 2/3 standards for industrial automation.

- Robustness: Designed to operate reliably in harsh industrial environments with minimal downtime.

Reviews

There are no reviews yet.