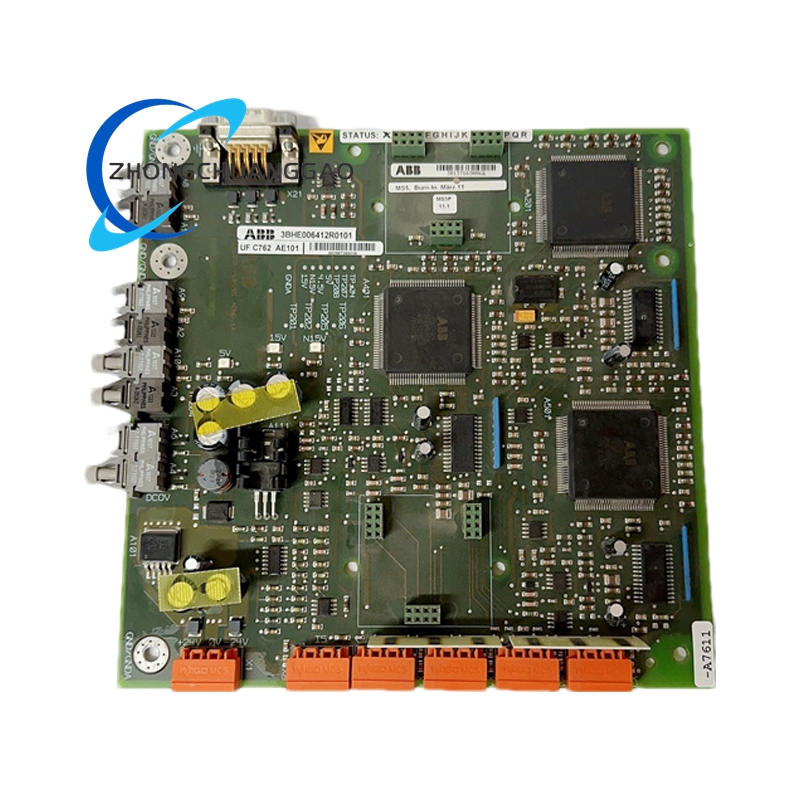

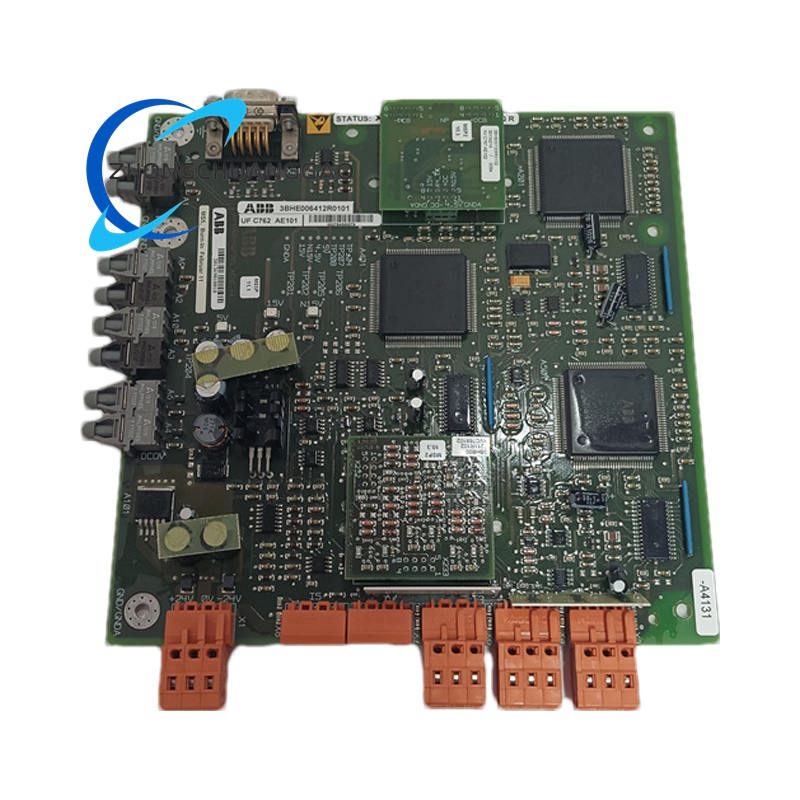

Product Short Description

Technical Specifications

- Processor: Quad – core

- Memory: 4 GB DDR3 (estimated, depending on configuration)

- Communication Interfaces: Modbus RTU, Ethernet (100BASE – TX, PROFINET/Modbus TCP optional), RS232/RS485 (depending on configuration)

- I/O Interfaces: Analog input: 4 – 20 mA (8 – 16 channels, depending on configuration); Digital I/O: 24 VDC (16 – 32 channels, depending on configuration)

- Power Supply: 24 VDC (18 – 32 VDC)

- Power Consumption: Approximately 10 W (typical)

- Protection Level: IP20 (EN 60529, for cabinet installation)

- Operating Temperature: – 25°C to +70°C (no condensation, humidity ≤95%)

Description

- Storage Temperature: – 40°C to +85°C

- Dimensions: 140 mm (length) × 61 mm (width) × 199 mm (height)

- Weight: Approximately 0.3 kg

- Certifications: CE, UL, CSA, TÜV, SIL 2 (IEC 61508, depending on application)

Functional Features

- Precise Control: It has high – precision speed and position control functions, which can quickly respond to system commands, ensuring the stability and accuracy of servo motors. It is suitable for complex motion control tasks such as high – precision positioning and trajectory tracking.

- Multiple Control Modes: Supports multiple control modes including speed control, position control, and torque control. Users can choose the appropriate control mode according to actual needs, flexibly adapting to various application scenarios.

- High – performance Processing: With a quad – core processor, it has a high – performance processing capacity, which can quickly process complex algorithms, and the measurement and control cycle is 0.5 seconds.

- Multi – axis Support: Can simultaneously control multiple servo motors, improving the flexibility and efficiency of the system.

- Easy Integration and Maintenance: Adopts a modular and standardized design, which is convenient for integration with other industrial equipment and systems. It also provides an intuitive user interface and powerful diagnostic tools for easy operation and maintenance.

- Rich Communication Interfaces: Supports high – speed communication interfaces such as RS232, Ethernet, Modbus, and CAN bus, which can quickly receive commands from the upper – level controller and feedback the motor status to the central system.

- Integrated Feedback System: It has an internal integrated encoder and position feedback function, which can monitor the rotation of the motor in real – time, ensuring precise positioning and control of the system at all times.

- Protection Functions: Built – in multiple protection mechanisms, such as over – current, over – voltage, over – heat and short – circuit protection, effectively preventing the system from malfunctioning under abnormal conditions and protecting the safety of equipment.

Application Scenarios

- Mechanical Processing Industry: Used in equipment such as CNC machine tools and automated production lines to achieve precise position and speed control.

- Automated Warehousing and Logistics Systems: In automated handling, sorting and stacking links, it controls servo motors to achieve efficient and accurate cargo handling.

- Energy and Power Industry: In the fields of wind power generation and hydropower generation, it controls servo motors to achieve precise angle and position adjustment.

- Industrial Robots: Used for robot control and operation.

- Medical Equipment: Used for the precise control of medical equipment.

Be the first to review “ABB UFC762AE101 3BHE006412R0101” Cancel reply

Reviews

There are no reviews yet.