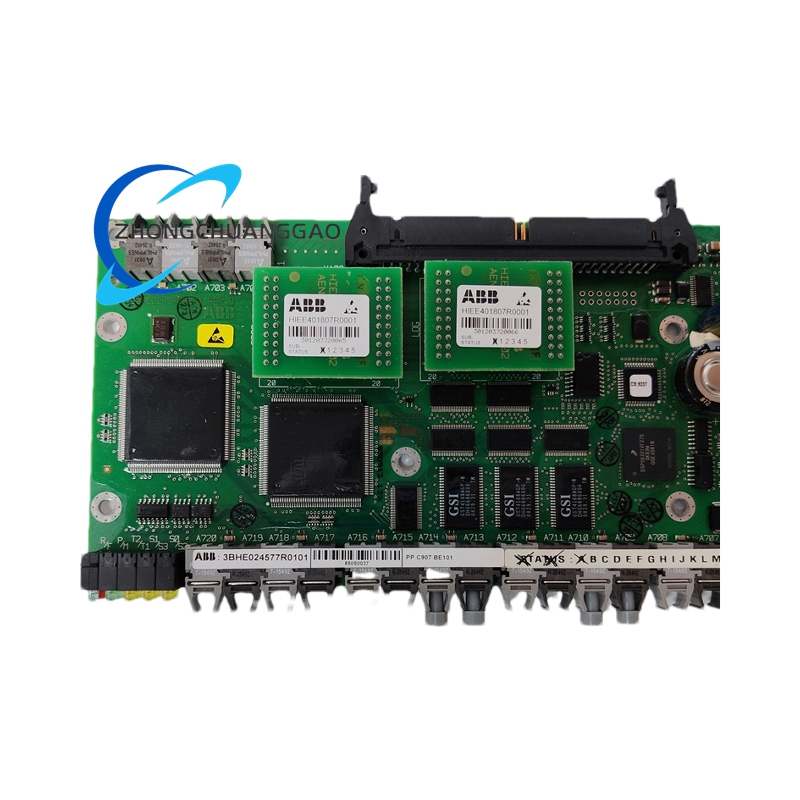

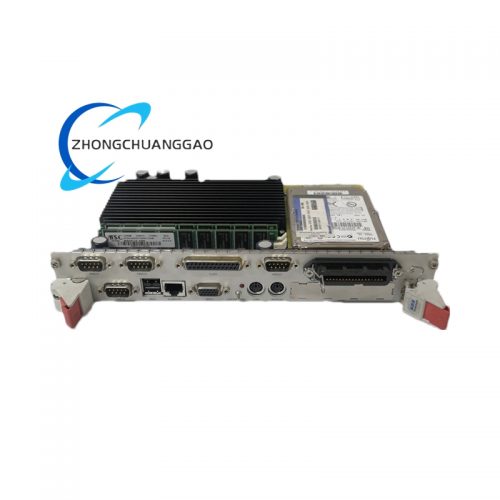

Product Short Description

- Core Hardware:

- Processor: 32-bit RISC CPU (high-performance multi-core architecture) .

- Memory: 128 MB RAM + 512 MB Flash storage (expandable) .

- Power Supply: 24 V DC ±10% (dual-range support for global compatibility) .

- Power Consumption: ≤4.5 W .

- Dimensions:

- Main Unit: 120 mm × 50 mm × 165 mm (L × W × H) .

- I/O Submodule: 22.5 mm × 60 mm × 101.5 mm (H × W × D) .

- Weight: 0.5 kg (I/O module) / 1.7 kg (full system) .

- Operating Temperature: -40°C to +70°C (industrial-grade range) .

- Protection Rating: IP20 (standard) / IP54 (harsh environments) .

Description

- I/O & Communication:

- Analog I/O: 12-bit resolution, ±0.1% accuracy (0–10V DC range) .

- Digital I/O: 16 DI + 16 DO (field-configurable) .

- Protocols: Modbus RTU/TCP, PROFIBUS DP/PA, Ethernet/IP, CAN bus .

- Ports: Dual RJ-45 Ethernet (100 Mbps), RS-232, RS-485 .

Functional Features

- High-Performance Control:

- Executes IEC 61131-3-compliant logic (ladder, structured text) for real-time process/motion control .

- Supports 1 MHz pulse counting for precision robotics and production tracking .

- Modular & Scalable Design:

- Hot-swappable I/O submodules for field upgrades without system downtime .

- Expandable via ABB AC 800M series FBMs (e.g., S800/S900 I/O) .

- Robust Industrial Engineering:

- Redundancy: CPU and communication redundancy for fail-safe operation (SIL 2 certified per IEC 61508) .

- Self-Diagnostics: Front-panel LEDs for power/network/fault status; logs >10,000 events .

- Conformal Coating: Resists chemicals/humidity in oil refineries, power plants .

- Smart Integration:

- Embedded web server for remote configuration via ABB Automation Builder or 800xA Control Builder .

- Cloud-SCADA compatibility (Ignition, WinCC) for real-time data historization .

Application Scenarios

| Industry | Use Cases | Key Functions |

|---|---|---|

| Power Generation | Turbine control (GE Mark VIe integration); grid stabilization | Real-time analog I/O monitoring; SIL 2 safety interlocks |

| Oil & Gas | Pipeline pressure safety; refinery valve networks | Modbus RTU leak detection; pump station automation |

| Manufacturing | Robotic welding (KUKA/PROFINET); assembly line synchronization | High-speed digital I/O; motion control logic |

| Pharmaceuticals | Batch reactor control; sterile filling machines | Precision temperature/pressure management |

| Water Treatment | Pump station flow monitoring; sewage parameter tracking | 4–20 mA sensor integration; fault diagnostics |

Compatibility & Integration

- Hardware Ecosystems:

- Controllers: ABB AC 800M, Honeywell Experion, Siemens S7-1500 .

- I/O Modules: ABB S800/S900 series; Allen Bradley 1794 .

- Software Tools:

- Engineering: ABB Control Builder for logic programming; System 1 for diagnostics .

- Third-Party: Ignition SCADA, WinCC .

Installation & Maintenance

- Deployment Guidelines:

- Mounting: DIN rail (EN 60715) with ≥50 mm ventilation clearance .

- Cabling: Shielded twisted pairs for analog signals; fiber optics in EMI zones .

- Preventive Protocols:

- Quarterly: Optical sensor calibration; connector cleaning with isopropyl alcohol .

- Annual: Firmware updates via Automation Builder; I/O channel validation .

- Troubleshooting:

- Boot Failure: Verify 24V DC stability; inspect capacitors .

- Network Latency: Check RS-485 termination (120 Ω) or Ethernet switch congestion .

Reviews

There are no reviews yet.