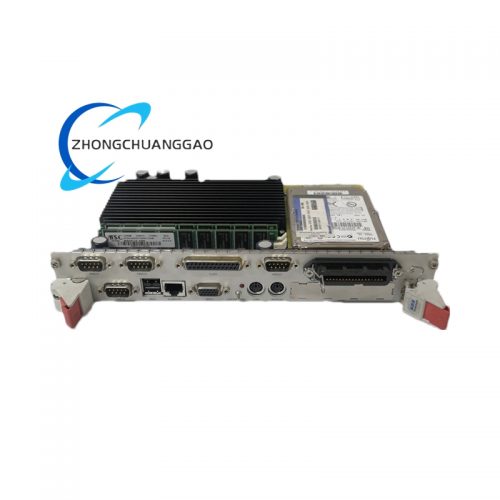

Product Short Description

- Processor: Dual-core ARM Cortex-A9, 800 MHz

- Memory: 4 GB eMMC storage, 2 GB RAM

- Communication Interfaces:

- 2 × Ethernet ports

- 2 × Serial ports (RS-232/RS-485)

- 1 × PROFIBUS DP interface

- USB 3.0/2.0 ports, SATA 3.0/2.0 interfaces, and Gigabit Ethernet LAN controller

- I/O Support:

- Supports up to 1,000+ I/O points for complex control tasks.

- Compatible with digital/analog signals and third-party devices via standard protocols.

Description

- Power Supply: 5–24 V DC

- Operating Temperature: -20°C to +60°C (extended range: -40°C to +85°C with PM866K01-EXT)

- Dimensions: 239 mm × 80 mm × 35 mm

- Weight: 0.72 kg

- Certifications: Complies with IEC 61131-3, SIL 2 safety standards.

Functional Features

- High Reliability:

- Built with industrial-grade components and redundant design to ensure continuous operation.

- Supports dual-controller redundancy for automatic failover during main controller faults.

- Efficient Data Processing:

- Dual-core processor and advanced algorithms enable rapid handling of control instructions and data analytics.

- Multifunction Integration:

- Combines logic control, data acquisition, signal processing, and communication in a single module.

- Precision Control:

- High-precision measurement and adjustment capabilities for parameters like tension, temperature, and pressure.

- Real-Time Monitoring:

- Provides live data visualization and alarm functions for proactive fault management.

- Security:

- Integrated fault diagnosis and emergency stop mechanisms to protect personnel and equipment.

- Programmability:

- Configurable via CODESYS software to define control strategies, alarm thresholds, and operating modes.

- Scalability:

- Modular design allows expansion with additional I/O modules or communication interfaces.

- Modular design allows expansion with additional I/O modules or communication interfaces.

Application Scenarios

- Industrial Automation:

- Controls manufacturing processes, assembly lines, and robotic systems in automotive, electronics, and machinery industries.

- Process Control:

- Manages complex chemical, petrochemical, and oil/gas processes, ensuring stable production and product quality.

- Energy Production:

- Monitors and controls generators, transformers, and grid equipment in power plants and renewable energy facilities.

- Building Automation:

- Optimizes HVAC, lighting, and security systems in smart buildings.

- Transportation:

- Coordinates traffic signals, monitors vehicle flow, and manages railway systems.

- Environmental Monitoring:

- Tracks air quality, water levels, and other environmental parameters in real time.

- Metal Processing:

- Controls tension in rolling mills and cutting machines for precise metal sheet production.

- Textile Industry:

- Maintains yarn/fabric tension during weaving and dyeing processes.

Industry-Specific Examples

- Automotive: A car factory achieved 0.1mm welding precision and reduced fault rates to 0.05% using PM866K01 for robotic arm control, cutting annual maintenance costs by $200,000.

- Oil & Gas: A refinery deployed the module for catalytic cracking unit control, enabling 24/7 operation with temperature accuracy of ±1°C and pressure stability of ±0.5 bar, boosting product yield to 99.9%.

- Renewable Energy: A wind farm integrated PM866K01 into its SCADA system, collecting data from 100+ turbines via Modbus TCP. This improved fault prediction accuracy and increased annual energy output by 5%.

- Water Treatment: A sewage plant used the module for dissolved oxygen control in aeration systems, reducing energy consumption by 30% and sludge production by 15%, saving $150,000/year in operational costs.

Reviews

There are no reviews yet.