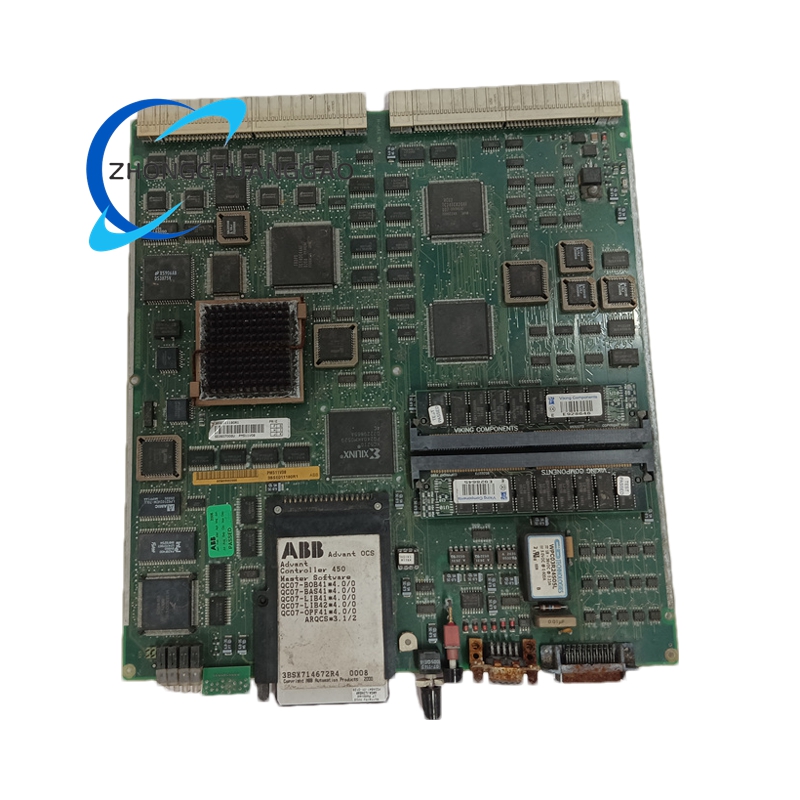

Product Short Description

Technical Specifications

- Processor Type: V08

- Input Voltage: 24 VDC

- Memory Configuration: 8 MB dynamic RAM with ECC (Error-Correcting Code)

- Dimensions: 150 × 130 × 200 mm

- Communication Interfaces:

- Supports multiple network types (e.g., PROFIBUS DP, Ethernet/IP)

- Device Type Manager (DTM) compatibility for seamless integration with communication devices

- Signal Types:

- Analog inputs/outputs: 4-20 mA, 0-10 V

- Supports high-precision signal acquisition for voltage, current, temperature, and other parameters

- Environmental Ratings:

- Operating temperature: -30°C to +70°C

- Protection class: IP67 (dust-tight, waterproof)

- Electromagnetic shielding for interference resistance

Description

Functional Characteristics

- High-Precision Data Acquisition:

- Real-time collection and processing of analog signals with minimal error and temperature drift.

- Resolution: 0.1 N (force measurement), adaptable to other physical quantities.

- Multi-Channel Input/Output:

- Simultaneous handling of multiple analog channels for efficient data management.

- Real-Time Communication:

- Enables rapid, stable data exchange with control systems (e.g., PLCs, DCS) for real-time monitoring and adjustment.

- Reliability and Stability:

- Designed for long-term operation in harsh industrial environments (vibration, humidity, extreme temperatures).

- Self-diagnostic functions for error detection and fault isolation.

- Flexible Integration:

- Supports custom output signals (4-20 mA/0-10 V) and protocols (Modbus, CANopen).

- Compatible with ABB’s DCS, PLC, and Millmate tension control systems.

Application Scenarios

- Process Control:

- Monitors and adjusts tension in paper manufacturing, textile production, and metal rolling to prevent defects (e.g., web breaks, uneven coating).

- Example: Reduced paper mill web breaks by 30% and improved coating uniformity by 20%.

- Data Acquisition:

- Collects analog signals (temperature, pressure, flow) for quality assurance in food packaging, battery production, and chemical processing.

- Example: Lowered fault rates by 40% in beverage packaging lines.

- Industrial Automation:

- Controls actuators (e.g., valves, motors) in energy management systems, factory equipment, and water treatment plants.

- Example: Cut yarn breakage by 60% in textile factories.

- Power and Petrochemical Industries:

- Manages analog signals in power plants, substations, and oil refineries for safe and efficient operation.

Industry Applications

- Manufacturing: Automation and quality control in automotive, aerospace, and electronics.

- Energy: Wind turbine control, solar panel production, and grid management.

- Metallurgy: Steel rolling mills and material handling systems.

- Petrochemicals: Refinery process monitoring and pipeline control.

- Water Treatment: Pump and valve control for wastewater management.

Advantages

- Durability: Stainless steel housing and IP67 rating ensure a 10+ year lifespan.

- Precision: ±0.02% FS accuracy for critical measurements.

- Low Maintenance: Self-diagnostics and dust/waterproof design reduce downtime.

- Scalability: Adaptable to small-scale sensors and large industrial networks.

Software and Tools

- Configuration: ABB Ability™ System 800xA for parameter setup and calibration.

- Diagnostics: ABB AssetCare software for remote monitoring and firmware updates (OPC UA compatible).

- Development: MotionLib dynamic library for custom application development.

Reviews

There are no reviews yet.