Product Short Description

High-speed data-processing board specifically engineered for ABB Pressductor Stressometer flatness-measurement systems in rolling-mill environments. It converts raw electromagnetic sensor signals into real-time flatness and tension data and delivers them to the mill’s DCS/PLC.

Description

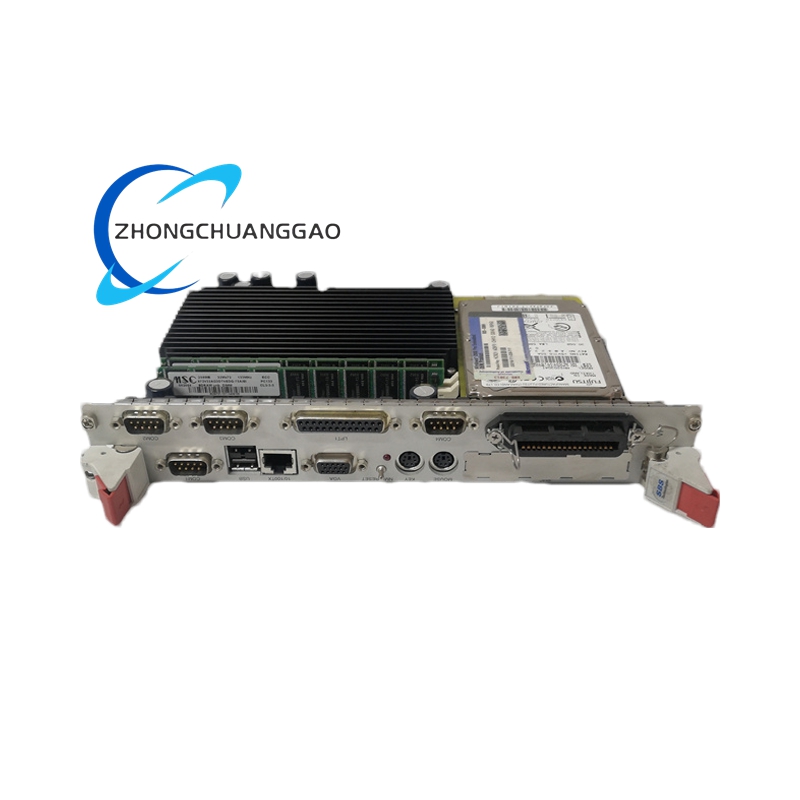

Technical Specifications

-

Part number: 3BSE027778R1

-

Internal model: VP74201-933CW07

-

Type: Industrial “server” / signal-processing board

-

Input: Analog/digital signals from Pressductor transducers

-

Output: Calibrated flatness, tension, and status data via high-speed internal bus

-

Communication: On-board diagnostic/configuration port (exact protocol proprietary)

-

Power supply: 24 V DC nominal (8–32 V DC operating range)

-

Current draw: ≤ 3 A at 5 V DC internal rail

-

Operating temperature: –40 °C to +80 °C

-

Humidity: 5 %–95 % non-condensing

-

Dimensions: Compact 6U plug-in board for ABB rack mounting

-

Certifications: CE, RoHS, UL recognized

Key Features

-

Real-time algorithm engine: Filters, linearizes and converts force signals to flatness values within millisecond cycles

-

Deep integration with Pressductor technology: Optimized for electromagnetic force sensors—no moving parts, high overload tolerance

-

Data quality management: Pre-processes and validates signals before forwarding to upper-level systems

-

Rugged design: Shock, vibration and EMC immunity for steel-mill environments

-

Hot-swap capable: Allows replacement without stopping the production line

Typical Applications

-

Steel rolling mills: Hot- and cold-strip mills, plate mills—real-time automatic flatness control (AFC)

-

Non-ferrous metal rolling: Aluminum, copper, zinc strip lines

-

High-precision tension/flatness monitoring in continuous process lines

-

Integration into ABB 800xA or third-party DCS for closed-loop shape control

Reviews

There are no reviews yet.