Product Short Description

ABB DSQC658 3HAC025779-001 is a high-performance signal conditioning module designed for industrial robotic systems. It serves as a critical interface between the robot controller and external devices, enabling precise control of single or dual-channel analog/digital signals. This module is widely used in ABB’s IRC5 and IRC5 Compact robot controllers to enhance signal accuracy and system reliability.

Description

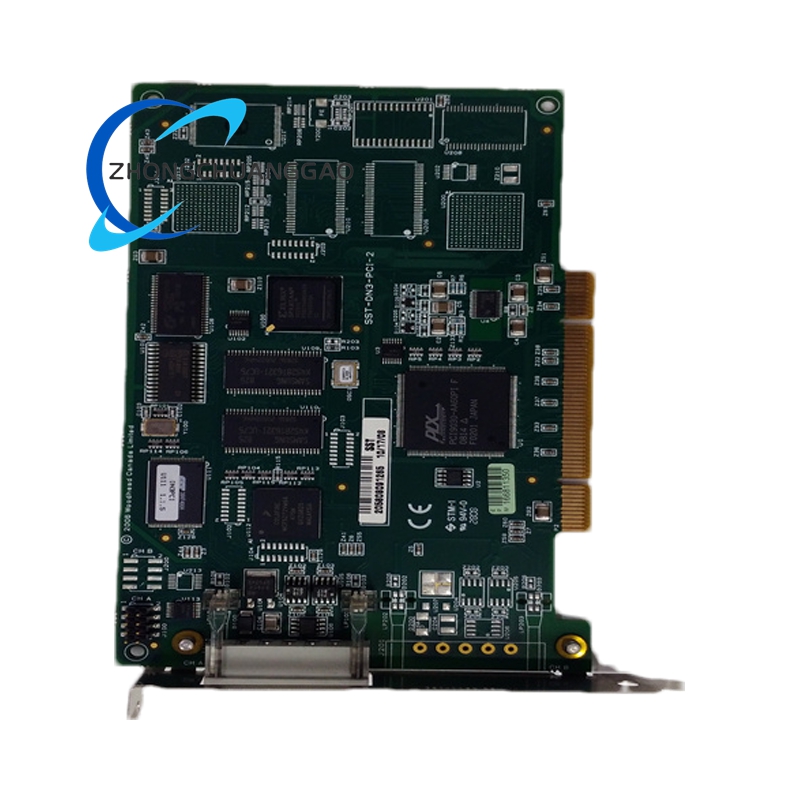

Technical Specifications

- Model: DSQC658 3HAC025779-001

- Type: Single/dual-channel signal conditioning module

- Voltage Range: 24V DC / 120V AC

- Output Frequency: 60Hz

- I/O Points: 40 points (configurable for analog/digital signals)

- Signal Types: Supports voltage (0–10V/5V) and current (0/4–20mA) signals

- Communication: Integrated with DeviceNet or DCS systems

- Operating Environment: Industrial-grade design for temperatures ranging from -25°C to +70°C

- Protection: Shielded against electromagnetic interference (EMI) and electrical noise

- Dimensions: 23cm (L) × 17cm (W) × 9cm (H)

- Weight: Approx. 1.5 kg

Functional Features

- High-Precision Signal Processing: Ensures accurate transmission of analog/digital signals with minimal latency.

- Multi-Channel Support: Configurable for single or dual-channel operation, reducing hardware complexity.

- Programmable Logic Control (PLC): Compatible with ABB’s RAPID programming language and RobotStudio software for flexible automation tasks.

- Real-Time Monitoring: Provides continuous feedback on signal quality and system status via integrated diagnostics.

- Robust Construction: Durable industrial-grade housing resistant to vibrations, temperature fluctuations, and corrosive environments.

- Safety Features: Supports emergency stop (E-stop) and collision detection functions to ensure safe robot operation.

Application Scenarios

- Automotive Manufacturing: Used in robotic welding, assembly, and painting lines for precise control of sensors and actuators.

- Electronics Assembly: Powers precision robots for component placement, soldering, and quality inspection.

- Metal Fabrication: Integral to CNC machining and metal cutting robots for accurate tool positioning and force control.

- Material Handling: Supports motorized grippers and conveyors in logistics automation systems.

- Power Generation: Deployed in电厂 (power plants) for monitoring and controlling turbine and generator operations.

- Cement & Paper Industries: Enhances process automation in cement kilns and paper mills through reliable signal transmission.

Key Advantages

- Seamless Integration: Compatible with ABB’s IRC5 controller ecosystem, simplifying system upgrades.

- Reduced Downtime: High-reliability design minimizes maintenance needs and operational interruptions.

- Scalability: Supports multi-robot configurations and distributed control systems (DCS) for large-scale automation.

- Global Support: Backed by ABB’s global service network, ensuring prompt technical assistance and spare parts availability.

Reviews

There are no reviews yet.