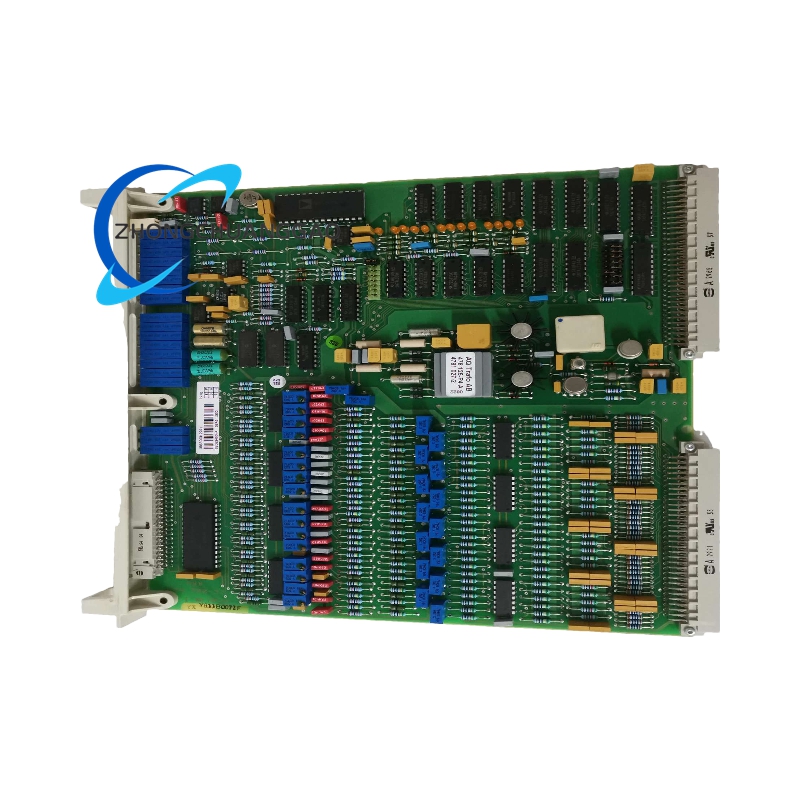

Product Short Description

Technical Specifications

- Module Type: Analog Input Module

- Input Channels: 8 differential channels (isolated between channels)

- Input Signal Types:

- 4-20 mA DC (current input, standard industrial signal)

- 0-20 mA DC (current input)

- 0-10 V DC (voltage input)

- ±5 V DC (voltage input)

- ±10 V DC (voltage input)

Description

- Input Resolution: 16 bits (ensures high-precision signal conversion)

- Input Isolation: 500 V AC (between channels; between channels and backplane)

- Accuracy:

- For 4-20 mA DC: ±0.1% of full scale (FS) at 25 °C

- For 0-10 V DC: ±0.1% of FS at 25 °C

- Sampling Rate: 10 samples per second (per channel, configurable for specific process needs)

- Operating Voltage: Powered via the Advant OCS/Symphony Plus backplane (typically 5 V DC logic supply, 24 V DC auxiliary supply)

- Power Consumption:

- Logic supply (5 V DC): Max 0.8 W

- Auxiliary supply (24 V DC): Max 1.2 W

- Operating Temperature Range: -10 °C to +55 °C

- Storage Temperature Range: -40 °C to +85 °C

- Humidity Tolerance: 5% to 95% relative humidity (non-condensing)

- Physical Dimensions: Approximately 100 mm (width) × 160 mm (height) × 220 mm (depth) (compatible with standard ABB DCS rack mounting)

- Weight: Approximately 1.8 kg

Functional Features

- High-Precision Signal Acquisition: Equipped with 16-bit ADC (Analog-to-Digital Converter) to ensure accurate conversion of analog field signals, minimizing measurement errors for critical process parameters.

- Channel-to-Channel Isolation: Each of the 8 input channels features independent electrical isolation, preventing cross-interference between channels and enhancing system stability in noisy industrial environments.

- Wide Signal Compatibility: Supports multiple standard analog input types (current and voltage), eliminating the need for additional signal converters and reducing system complexity.

- Built-in Self-Diagnosis: Continuously monitors internal module status (e.g., ADC functionality, power supply, and communication links). Triggers alarms and sends diagnostic data to the DCS controller if faults are detected, enabling quick maintenance.

- Rack-Mounted Integration: Designed for seamless installation into ABB Advant OCS/Symphony Plus standard racks, with standardized backplane communication to ensure plug-and-play compatibility with the DCS.

- Environmental Robustness: Operates reliably within a wide temperature range and high humidity conditions, meeting the durability requirements of harsh industrial sites (e.g., chemical plants, power stations).

- Noise Immunity: Incorporates electromagnetic interference (EMI) filtering technology to suppress external electrical noise, ensuring stable signal transmission even in environments with heavy machinery or high-voltage equipment.

Application Scenarios

- Power Generation Industry: Used in thermal power plants and nuclear power plants to acquire analog signals from sensors monitoring steam pressure, feedwater flow, turbine oil temperature, and generator exhaust gas temperature, supporting DCS-based process control and safety monitoring.

- Chemical and Petrochemical Industry: Applied in chemical reactors, distillation columns, and oil refineries to collect data from pressure transmitters, temperature sensors, and flow meters, enabling precise control of reaction conditions and ensuring compliance with production quality standards.

- Oil and Gas Industry: Deployed in offshore platforms, oil pipelines, and natural gas processing plants to monitor wellhead pressure, pipeline flow rate, and gas composition (via analog sensors), facilitating remote process control and leak detection.

- Water and Wastewater Treatment: Used in water treatment plants to measure parameters such as water pH value, turbidity, and chemical dosage (e.g., chlorine concentration) via analog sensors, supporting automated treatment process control and ensuring effluent quality meets regulatory requirements.

- Pharmaceutical Industry: Integrated into pharmaceutical production lines to monitor temperature, pressure, and viscosity of drug synthesis processes, ensuring compliance with GMP (Good Manufacturing Practices) through high-precision analog signal acquisition and traceable data logging.

- Metallurgical Industry: Applied in steel mills and aluminum smelters to collect signals from sensors monitoring molten metal temperature, furnace pressure, and rolling speed, enabling real-time adjustment of production parameters to improve product quality and reduce energy consumption.

Be the first to review “ABB DSAI130D 3BSE003127R1” Cancel reply

Reviews

There are no reviews yet.